- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cable stripping

Results for

Cable stripping - Import export

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 5000 range includes the flagship models for precise processing of thick cables up to 240 mm² section and 35 mm diameter. Even the basic specification models, with their high torque and powerful three-stage step motors offer the highest level of cutting and haul-off power. All models are equipped with as standard with the Metzner double-knife system that enables very varied and multi-stage processes to be performed. Moreover, with convincing operator-friendliness and long service life. Metzner AM 5000 models are also suited to processing thinner braided cables from 1.5 mm² The stripping full haul-off 1side/2nd side amount to 270-450 mm and 90-270 mm, for partial haul-off 450 mm and 270 mm. For interuption-free automatic production, a number of sensors monitor the material feeding If a material blockage occurs, the production stops automatically and the operator is informed about the cause of the fault.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

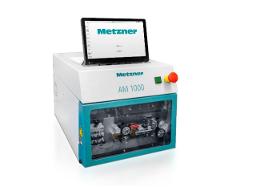

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable to form a cable ring.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cable stripping - Import exportNumber of results

5 ProductsCountries

Company type