- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium steels

Results for

Aluminium steels - Import export

QUELLTECH GMBH

Germany

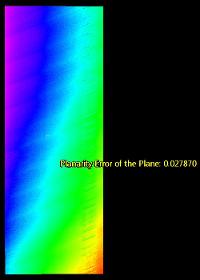

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution: The performance of a manual inspection cannot be compared with the speed and the repeatability of a contactless QuellTech Q4-1000 laser scanner. It is even possible to install several instruments in parallel to cover the whole width of the ingot with one single scan. These instruments are mounted on an existing portal and correctly synchronized, so that interaction of the laser light originating from the other scanners is excluded. The QuellTech laser line scanners produce 3D point cloud of the raw ingot surface, and the software calculates the coordinates of the highest and deepest levels of this surface. After scalping the flat surface can be scanned again for any defects. Benefits for the Client: Thanks to QuellTech’s wide area laser line scanners, the cycle times for ingot scalping could considerably be reduced, and excessive material scrap due to a too low scalping level is prevented.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Through the process of briquetting, the value of residual metals can be increased considerably. The value of residual metals can be increased considerably. A further advantage is the recovery of expensive cutting fluids that can be pressed out of wet chips and then reused. When melting briquettes, combustion is significantly lower and results in a higher melting yield than with loose chips. Depending on the need, our briquette systems are equipped with hydraulic motors between 4 and 90 kW. They will achieve a specific pressure of up to 5,000 kg/cm². Suitable for aluminium, steel, cast iron, copper and many other metals Advantages: - Heavy reduction of volume, reducing storage and transportation costs - Recycling of expensive cooling lubricants - Recipients often pay a better price for loose millings - Minimal burn-off and increased glaze recovery thereby For throughput rates between 30 and 4,800 kg/hr.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Based on a individual needs assessment we tailor-make briquetting solutions including peripheral devices. RUF- Charging hopper with screw conveyor for charging & transporting of bulk material as aluminium, steel, stainless steel, other metals, wood, other bulk materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GESCO-METALL GMBH SCHOTTENHAMML-BIEGETECHNIK

Germany

The two basic designs in stainless steel and aluminium are available in standard sizes of 200 mm, 250 mm, 300 mm, 350 mm, 400 mm, 500 mm (cut-out in the door panel / nominal diameter). Portholes are available in five standard design versions – invisibly screwed (A), visibly screwed on one side (B), visibly screwed on both sides (C), with flat-leaf screw fitting (D) and with folded screw fitting (E). Our portholes can be fitted in Internal doors House doors Panels Facades Surfaces Aluminium Press plank, ready for powder coating Finely brushed, anodised RAL powder-coated Stainless steel Finely brushed

Request for a quote

IPR GMBH

Germany

for hexagonal crimp of Aluminium Steel Cables with Aluminium tube: 120/20; 150/25 DIN 48083

Request for a quote

IPR GMBH

Germany

for hexagonal crimp of Aluminium Steel Cables with Steel tube: 50/8 DIN 48083

Request for a quote

IPR GMBH

Germany

for hexagonal crimp of Aluminium-Steel Cables with Steel tube: 120/20; 150/25 DIN 48083

Request for a quote

IPR GMBH

Germany

for hexagonal crimp of 10mm² Cu and Aluminium-Steel Cables with Steel tube: 16/2,5; 25/4; 35/6 DIN 48083

Request for a quote

NORIS GROUP GMBH

Germany

Non-contacting speed sensor type FA54 withNon-contacting speed sensor type FA54 with aluminium flange and stainless steel sensor tube. Due to its design and its approvals especially suitable for the shipbuilding industry. Robust and high quality housing: IP68 pressure-tight Excellent vibration and shock resistance High degree of EMC immunity for difficult electrical environment Connection outlet straight or lateral; with protective tubing on request Up to four output signals, on request available with one status signal for rotational direction detection, on request with two galvanically isolated output signals

Request for a quoteResults for

Aluminium steels - Import exportNumber of results

12 ProductsCompany type