- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- multi-saw

Results for

Multi-saw - Import export

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HCS MULTI-FLUID is a series of carbide circular saw manufactured by Eisele. The key highlights of the HCS MULTI-FLUID series include a firm base frame that is welded, a bigger scope of cutting, an arbitrary saw blade that is accessible to ensure maximum cutting scope that can reach up to 180 mm . The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickelbasedalloys like Inconel and Hastelloy as well as titanium alloys. Depending on the requirements, the following cooling/lubrication components can be combined in a most effective way: — Coolant nozzles for wet processing — Micro-spraying device for minimum quantity lubrication — Cooling vortex tube for dry cutting

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

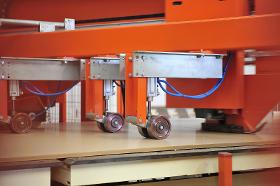

The boards are cut o the endless mat in the saw section. The process becomes a discontinuous one that is characterised by cycle times from this point on. The saw section includes the board edge-trimming and saw units. The board is cut by saws that are positioned at right angles to the endless board and that cut straight proportionally to the feed of the press. It is possible to change the tools without interruption to the production process depending on the number of individual units. longitudinal edge trimming device 2 edge-trimming units – no production possible while tools are being changed 2 edge-trimming units with the option for retrotting additional units 4 edge-trimming units for interruption-free changing of the saw blades Bevelling of the endless board after trimming Multi-diagonalsaw Up to two saw beams each with two units, i.e. four saws maximum Number of saws depending on the feed and desired board length

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The DW292 is specifically designed for cutting monocrystalline silicon ingots up to 300mm diameter into high quality wafers for the semiconductor industry. The newly developed DW292-300 can be operated with slurry wire, as well as with diamond wire, and has sophisticated features for optimizing warp and ripple. The longer wire field, as well as the higher wire speed and acceleration, enable a higher throughput per machine and year. The use of extremely thin wire is possible thanks to smaller inertia of moving parts, fewer deflection rollers and shorter wire distance. The DW292-300 is highly resistant to temperature fluctuations and vibrations due to its compact and robust machine frame made of mineral casting. Thanks to higher process automation and the new intuitive HMI with dialog-based production wizard, operation is safer, easier and faster.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Multi-saw - Import exportNumber of results

3 ProductsCountries

Company type