- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mould making

Results for

Mould making - Import export

ZANDER GMBH

Germany

Three-dimensional shapes and tools implemented in steel and aluminum. Our services Moldmaking develops and manufactures tools for your products based on models, datasets and drawings. Manifold mandrels, tools for cooling water, fuel, heating and air hoses and other special applications Vulcanizing molds for air conditioning hoses with high accuracy in steel and aluminum Milling mandrels for hoses in stainless steel and aluminum Punching tools for elastomers Special production in steel, stainless steel and aluminum Turning - CNC machine CTX 420 with driven tools and Y-axis Milling - CNC machine DMU 80, five axes simultaneously

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD SLV is a universal two-component fast casting PU resin for mould making. It is used for the production of milling devices, negatives, product holders, foundry moulds, mould plates, copy moulds, core boxes, pattern plates, casting moulds, prototype parts, supporting moulds and synthetic cast. It consists of a beige-brown low viscosity resin component A (polyol mixture) and a red-brown, low viscosity hardener (component B) based on isocyanate (Methylendi(phenylisocyanat)e = MDI). Two types are available with different pot life: *ALWA MOULD SLV 3 ~ 3 min. pot life *ALWA MOULD SLV 9 ~ 9 min. pot life

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

Using thermoforming as an alternative to metal, foam or injection moulding often makes economical sense, especially where mid-size production runs or complex components are involved.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Optimel is your reliable partner for solutions for encapsulating electrical and electronic assemblies. The innovative Low Pressure Moulding (LPM) technology offers optimal protection against external influences such as moisture, dust and vibrations, thus ensuring the longevity and reliability of your products. The Low Pressure Moulding process or hotmelt moulding process originated in the sealing of cable harnesses in the automotive industry - today it is used in many areas for the protection of electrical and electronic components. At 5-40 bar (in individual cases up to max. 60 bar), processing takes place at a much lower pressure than in the classic hotmelt injection moulding process. This makes it easy to directly encapsulate even sensitive components such as circuit boards, sensors, etc. The cycle times are limited to pure encapsulation

Request for a quote

CRAEMER GMBH

Germany

The CB1 pallet box from Craemer is one-piece injection moulded with three runners, making it highly robust. Further impact protection and resistance to forklift tines is provided by additional ribs over the entry openings of the closed exterior walls. The seamless construction and smooth interior walls of this large load carrier ensure easy emptying, simple cleaning and good drying capabilities. Integrated stacking cams on the outer corners give stacked pallet boxes a secure hold. Dimensions L x W x H: 1200 x 800 x 740 mm Weight: 34,5 kg Volume: 470 L Material: PE Load capacity: Stacking Load 5000 kg, Holding Capacity 700 kg, Dynamic Load 1200 kg Runners: 3, unwelded Integrated locking corners for secure stacking Stippled area for adhesive labels Ram protection through added side reinforcements Smooth interior walls Container corresponds to DIN EN 13626 and DIN EN ISO 12048 Option: — RFID transponder — Lid — Individual printing — Available in various colours

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

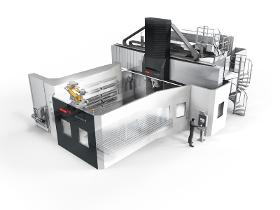

STARRAG GMBH

Germany

With the T/TF series, Droop+Rein offers gantry machining centres for heavyduty machining in many sectors Applications range from tool and mould making, aircraft component manufacturing and engine manufacturing to general mechanical engineering. Based on the robust, highly accurate and powerful basic machines, the T/TF series offers an extensive system of innovative automation and expansion stages that enable the machines to be adapted flexibly to each machining task. The optional automatically changing forktype milling head makes complex and demanding machining possible. Through extensive application knowhow, a variety of different milling heads are available including vertical milling heads, angle milling heads, and forktype milling heads for positional or simultaneously controlled applications.

Request for a quoteResults for

Mould making - Import exportNumber of results

8 ProductsCountries

Company type