- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling solutions

Results for

Milling solutions - Import export

ROSE PLASTIC AG

Germany

Plastic cases sturdily designed for all-around protection of high-quality milling cutter heads Extremely strong blown double-wall case Secure center fixing screw offers high protection of cutter edge Centering points on base and cover for secure stacking

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Over 130 successfully completed projects worldwide. With the combination of the understanding of the whole rolling process and the experience with modern control methods, we have implemented modernisation solutions in many rolling mills that have significantly improved the quality of the finished product and the efficiency of the production. For thickness control, for example, we convert mills from electric motor to servo-hydraulic screwdown of the stands. We also replace pancake cylinders or the combination of spindle and hydraulic screwdown with modern long-stroke cylinders. Vollmer has already modernised mills with a rolling force of 3,000 t. For the modernisation of the shape control system, too, Vollmer offers complete solutions through to the control and modification of the adjusting elements.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

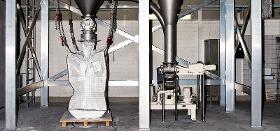

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Drug Mill The economic solution for grinding your natural products The drug mill used by us enables an economical external grinding of leaf drugs, herbs and plant roots for our customers. This way our clients save having to invest in their own, only mills that would only be fully utilized seasonally – at the same time they remain flexible with the production of teas, remedies or natural cosmetics. Technical data Throughput: 0,5-3 to/h Target fineness: 1-15 mm Product-contacting parts: Stainless steel Cleanability: Completely cleanable Grinding plant: Granulator with screen insert Feeding: Via bunker with clearing device and double shaft screw Container: Feeding as bagged goods, bales, Big Bags, octabins or in drums Areas of application Grinding of drug precursors Grinding of willow bark Grinding of St. John's wort Grinding of tea leaves Grinding of plant roots After grinding, filling in Big Bags or other containers Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Cryogenic Mill The solution for fine grinding temperature-sensitive products. Our cryogenic grinding plants enable fine grinding of lubricating and temperature-sensitive products. This not only results in a technically perfect grinding but in addition thermal damage of the ground material and resulting grinding losses are prevented by the cryogenic grinding. All plants are designed with swivel screw coolers and liquid nitrogen cooling, appropriate dosing devices, separators as well as bunkers as closed plants. Technical data Target fineness: 10-2,000 µm Plant types: Pin mills, cross beater mills Product-contacting parts: Stainless steel Cooling: By liquid nitrogen Delivery in: Bagged goods, Big Bags, oktabins, drums Feeding: Via feeding stations, metering screws and vertebral screw coolers Filling into: Bags, drums, Big Bags, cardboard boxes and special containers Areas of application Fine grinding of resins Fine grinding of foodstuffs Fine grinding of seeds Fine grindi

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: rectangular tube, round edged Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 1.8 -3 Length (mm): 6,000 Height (mm): 15 - 40 Width (mm): 25 - 80 Radius (mm): 2 - 6

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: EN AW-2017 (AlCuMg1), 3.1325, T451 Type of manufacture: rolled Condition: solution annealed, cold aged Surface finish: mill-finish Standard: EN 573/EN 485 eClass 9.1: 35020501 UNSPSC 11.2: 30102506 Dimensions: Thickness (mm): 2 - 3 Length (mm): 2,000 Width (mm): 1,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: rectangular tube, 2 centre crossbars Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 573-3, 755-1/-2/-9, EN 15088 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 Length (mm): 6,000 Height (mm): 18 Width (mm): 200

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

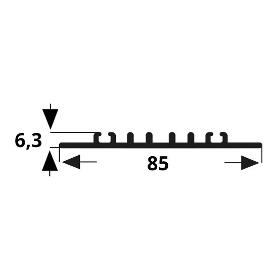

Shape: grooved butt connector, perforated Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, not completely artificially aged Surface: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Width (mm): 85 Length (mm): 6,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: round Material: EN AW-6060 (AlMgSi0,5), 3.3206 Manufacturing method: pressed Surface quality: mill-finish Condition: solution heat-treated, artificially aged Norm: DIN EN 573-3 eClass 9.1: 35020302 UNSPSC 11.2: 30102406 Dimensions: Diameter (mm): 6 - 60 Length (mm): 6,000

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 30 and FZ 35 Portal Milling Machines are the economical solution for a vast variety of tasks. For finishing, and with the FZ 35 even roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 35 Portal Milling Machine is the economical solution for a vast variety of tasks. For finishing and roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quoteResults for

Milling solutions - Import exportNumber of results

13 ProductsCountries

Company type