- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling and turning

Results for

Milling and turning - Import export

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

STARRAG GMBH

Germany

The 5axis Mill / Turn center model s128 is a perfect combination of maximum performance and minimum footprint. On less than 2m², the s128 is a concentrate of high technology; Milling, Turning, Drilling, Engraving, Setting preparation and Diamond cutting processes are possible to produce parts as single unit or as serial manufacturing. The machining of miscellaneous parts from bar or blank and demanding perfect surface quality can be achieved with very short changeover time. Features Compact machine less than 2m² Flexible manufacturing solution Production from bar or blank 5Axis simultaneously

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

ROHRE-KETTERER GMBH

Germany

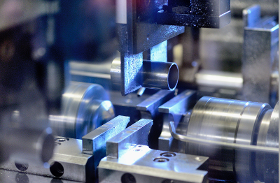

Stamping of especially thin-walled tubes with high demands on precision and a burr-free surface is one of our specialities. We are stamping with full and half automated stamping units and can produce any stamping geometry in one clamping withoud deforming the parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

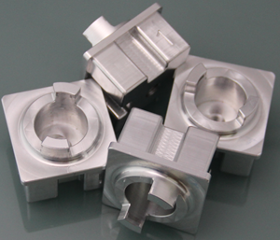

These accessories use for precision machinery.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These the parts made by aluminum, used for machines accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in gas detector.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Valve screw mechanical accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are made by aluminium, used for the mechanical support and connection, after process then doing sandblasting + natural oxidation.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories use vintage car, the surface including :brush + bright anodize, brush + black anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the assembly parts of air valves.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in valve accessories series products,which is made by aluminum.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in the valve accessories,the main function is to strengthen the valve,and ensure the normal flow of gas,to make sure the valve is working properly.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This parts are use for automobile brake accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flake,custom machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is the accessoris used for sensor, after machining, and then process black anodize.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The parts used in connecting pipe.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Aluminium gasket.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turn-milling compound machining flange

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in assemble flashlight accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in audio equipment accessories.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Flexible production of crankshafts and camshafts Machine series for perfect internal and external milling - as stand-alone machine or linked manufacturing system Highlights Internal and external milling of crankshafts Turn-chasing of crankshafts External milling of camshafts Advantages Unique HELLER know-how of the complete process chain Use of a combination of different technologies Dependable process control

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Most modern equipped, we meet your demands on highest level! For the mechanical processing, we use modern manufacturing technologies which ensure tailor-made optimized solution on a constantly high quality level. Whether individual parts or small and medium-scale productions, whether small components or XXL parts, we remain at your service. For the customer's data transfer, our modern 2D & 3D CAD systems are available. ■ CNC turning: up to 3000 mm / Ø420 mm (118"/Ø16") ■ CNC milling: up to 7000/2500/1500 mm (275"/98"/59"), part weight up to 10 T (2204 lbs) ■ 5-axis treatment up to Ø 1000 mm (39"), part weight up to 1,2 T (2645 lbs)

Request for a quoteResults for

Milling and turning - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Sensors (3)

- Turning - steels and metals (2)

- Machine tools, metal machining - parts and accessories (2)

- Mechanical engineering - custom work (2)

- Automobiles (2)

- Household appliances, electrical - import-export (2)

- Milling - steels and metals (1)

- Steels and metals - machining (1)

- Aerosol valves (1)

- Agricultural machines and accessories (1)

- Astronomy - instruments and equipment (1)

- Cabinetmaking - machinery and equipment (1)

- Cocks and valves for petroleum and petrochemical industries (1)

- Construction cranes (1)

- Dynamos (1)

- Heating and air conditioning - works (1)

- Machine tools - metal machining (1)

- Medical and surgical optics - instruments (1)

- Pharmaceutical industry - machinery and equipment (1)

- Radiators, engine (1)