- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling and drilling

Results for

Milling and drilling - Import export

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and suited for milling and drilling applications.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Powerful, long-lived, precise: GMN motor spindles for manual or automatic tool change stand for quality and efficiency, and are well-suited to your grinding, milling, drilling or special applications.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications. GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

ROSE PLASTIC AG

Germany

Hexagonal telescopic plastic packaging tubes with ratchet length adjustment. Ideal for drills, milling cutters, shank tools, tool holders and tool bits Infinitely variable telescopic length adjustment Speedy efficient packaging Speedy handling

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PERFECTLY EQUIPPED FOR EVERY TASK! - The TFZ series offers intelligent solutions from A to Z. STABILITY AND HIGHEST PRECISION DO NOT COME FROM ABOUT BY CHANCE. - Static and dynamic optimization of the components in the power flow - Permanent dimensional accuracy and prevention of tolerance overlap - Minimum distance between pivot bearing and tool center point (TCP) WE KNOW WHAT IS IMPORTANT WHEN IT COMES TO OPERATION AND MAINTENANCE. - Easy crane loading thanks to simultaneous opening of the front and roof doors - Generous sliding doors to the work area - Additional viewing window - Tool magazine & tool rack arranged internally for quick changeover | optional: external & automatic tool changer - User-friendly service access TRUST IS GOOD, CONTROL IS BETTER! - Guarantee of professional machining, long tool life and prevention of accidents & breakdowns - Precise process monitoring during machining

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

TBM flex – special deep drilling and milling centers – deep drilling and milling in one machine Modular system for drilling and milling For individual part and small series production Peeling and rolling possible Processing of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

Universal centring microscope to set up tool machines (for example drilling and milling machines).

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

Universal centring microscope to set up tool machines (for example milling or drilling machines). The edges of a workpiece can be positioned, rotary stages can be centered or machine spindles can be aligned. The centring microscope is fixed in the machine instead of the tool. the image is true erect and with high contrast the eyepiece has a graticule with crosshair and concentric circles LEDs are used for the incident light 5 µm centring accuracy can be achieved DIN 2080-A 40 (short taper) standard fixture

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Milling and drilling combined in one machine - In tool and mold making, complex cubic workpieces can be machined precisely, powerfully, safely and from all four sides in just one clamping. The machining centers in the TFZ series cover all requirements in small, medium and large mold making. But TFZ machines are also used in mechanical engineering and the hydraulic industry. You can obtain suitable solutions for machining spindle housings, gear housings or hydraulic cylinders from the deep drilling specialist. Position tolerances in the range of +/-1/100 Angle tolerances +/- 0.02° Surface qualities for ELB drilling Rz 1.6 Cutting volume of 1,600 cm³/min Deep drilling using the ELB process also for diameters larger than 60 mm

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quote

STARRAG GMBH

Germany

Thanks to the integrated DBF spindle head, the complex production in the processes turning, drilling and milling can be realized in one single workspace. Available in 5 and 6axis versions

Request for a quote

STARRAG GMBH

Germany

Finishing centers for the jewelry industries, the machines range s210/ s220 combine several processes such as Milling, Engraving, Drilling and Faceting to produce parts for the most demanding key players of the jewelry crafts worldwide. His legendary finishing qualities best fit the requirements in terms of accuracy and ease of use. Features 6 to 8Axis Faceting, engraving, drilling, milling 2 spindles with changer and tool magazine High frequency 45.000min1 spindle Easy changeover of the programs CNC control unit Siemens 840Di

Request for a quote

STARRAG GMBH

Germany

The 5axis Mill / Turn center model s128 is a perfect combination of maximum performance and minimum footprint. On less than 2m², the s128 is a concentrate of high technology; Milling, Turning, Drilling, Engraving, Setting preparation and Diamond cutting processes are possible to produce parts as single unit or as serial manufacturing. The machining of miscellaneous parts from bar or blank and demanding perfect surface quality can be achieved with very short changeover time. Features Compact machine less than 2m² Flexible manufacturing solution Production from bar or blank 5Axis simultaneously

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

PERO AG

Germany

Cleaning of machined parts (after turning, milling, drilling, etc.). Particularly suitable for the removal of graphite, AW and EP additives, salts, soaps, and emulsion residue. Generally suitable for the removal of dust, metal chips, surfactants, stearates and polishing paste. Preparation of parts for downstream processing such as joining (by clinching, etc.), assembly and packaging. Cleaning of machined parts (after turning, milling, drilling, etc.). Particularly suitable for the removal of grease, oil, wax, resins, corrosion protection agents and esters. Generally suitable for the removal of dust, metal chips, surfactants, stearates and polishing paste. Preparation of parts for downstream processing such as joining (by clinching, etc.), assembly and packaging. Cleaning of machined parts after turning, milling or drilling, grinding, polishing, lapping and honing, punching and forming (stamping & bending, deep drawing, extruding, etc.).

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Digital readouts from HEIDENHAIN are used in a wide variety of applications. They are deployed on machine tools, infeed axes on saws and presses, measuring and inspection equipment, dividing apparatuses, setting tools, production inspection measuring stations, and more. To meet such demands, these digital readouts can also be used in combination with numerous encoders from HEIDENHAIN. Digital readouts with multiple axes are primarily used on manually operated machine tools, where their practical cycles provide optimal support to the operator during milling, drilling, or turning. By instantly displaying the position in an easy-to-read manner, digital readouts enable a significant increase in productivity.

Request for a quote

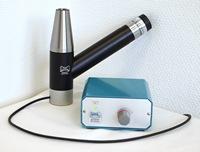

FISCHER FORTUNA GMBH

Germany

Compact spindle with asynchronous motor for micron machining with speed up to 65,000 rpm. Due to the bearing arrangement the PRECISE SC3164 can be used for light milling and drilling application and also for grinding application. Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact motor spindle for micron machining with speed up to 80,000 rpm. Due to the bearing arrangement the PRECISE SC2063 can be used for light milling and drilling application. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact spindle with asynchronous motor for micron machining with speed up to 15,000 rpm. Due to the bearing arrangement the PRECISE ESC4094-MAC can be used for light milling and drilling application and also for grinding application. Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quoteResults for

Milling and drilling - Import exportNumber of results

67 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (14)

- Measurement - Equipment & Instruments (5)

- Mechanical engineering - custom work (2)

- Machine tools - metal machining (1)

- Drilling - machine tools (1)

- Plastic packaging (1)

- Adjustment - machine tools (1)

- Cleaning machines, industrial (1)

- Engraving, industrial - steels and metals (1)

- Metallurgy - machinery and installations (1)

- Numerical control systems - minicomputers and mainframes (1)

- Punching machines, plastic (1)

- Taps - adjustable controls (1)