- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metering pumps

Results for

Metering pumps - Import export

WITTE PUMPS & TECHNOLOGY GMBH

Germany

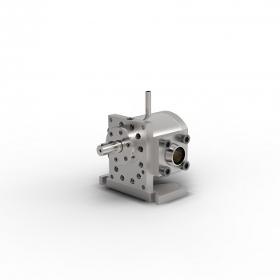

Stainless steel metering gear pump for the delivery of chemical raw materials for the production of pharmaceutical products. CHEM metering pumps are also used to pump isocyanate, sulphuric acid, polyol or essential oils. With the appropriate combination of materials, many critical applications can be realized and a variety of low-viscosity fluids can be pumped. The range of applications extends from classic transfer and metering tasks in the chemical and pharmaceutical industry to the pumping of monomers, oligomers and prepolymers in polymer production. These chemical pumps are suitable for even the most difficult tasks and impress with their reliability and dosing accuracy in both vacuum and high-pressure applications. Typical applications for this pump type are in the chemical, cosmetics, food, petrochemical and polymer industries

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Stainless steel gear pump for the delivery of alcohols, isocyanates or gels. The exact volumetric dosing of this series guarantees a low-pulsation and constant flow rate. Due to its compact size and high precision, the CHEM MINI is ideally suited for use in laboratories. Parts in contact with the medium can be made of stainless steel or ceramic materials. The series is available in sizes from 0.2-9-5.5 to 2.95-14-28, other sizes are also available on request. The range of application covers classic transfer and dosing tasks in the chemical and pharmaceutical industry. Due to decades of design experience and optimum material selection, this pump type is suitable for even the most difficult tasks and convinces by its reliability and dosing accuracy in vacuum applications.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The CHEM gear pump series was developed especially for the requirements of the chemical industry. The series is used for pumping and transferring low to medium viscosity media. The CHEM series is extremely flexible in its design and areas of application. Technical details: — Suction pressures from vacuum up to 15 bar and suction pressures with magnetic coupling up to 25 bar — Delivery volume 1.28 cc/rev to 12,000 cc/rev — Temperatures up to 300 degrees — As special pumps for the chemical industry according to customer specifications — Viscosities up to 1.000.000 mPas

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Witte chemical pumps are used as dosing pumps for a variety of fluids. Pumps of the CHEM series are designed and assembled exclusively at the Tornesch site, thus guaranteeing highest reliability and quality. For all our series we offer a comprehensive spare parts service on request. In addition, we also install the pumps directly at our customer's plant. Dosing pumps of the CHEM series are extremely flexible in their design and can be offered in various variants and equipment thanks to a modular system. Differential pressures up to 120 bar, suction pressures vacuum up to 15 bar Temperatures up to max 500 °C in combination with a magnetic coupling. Viscosities up to 1.000.000 mPas or higher Components made of stainless steel, ceramic and special materials Flow rates from 20 l/h to 170,000 l/h

Request for a quote

DEMAREIS GMBH

Germany

Whether for canisters or bottles with good stability, our high-quality metering pumps have an output from 10 until 30 ml. We have the matching closure sizes, also with tamper evident protection available in 38, 43 and 45 mm.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Easy to operate, compactly built and quick to mount on all Drum- and container pumps: the new Lutz Flow Meter TR3 in PP or PVDF. A handy meter that you can "count on" in any situation. The symmetrical measuring chamber allows it to be used for all flow directions and measures low-viscosity, non-flammable media precisely, quickly and, above all, efficiently. * PP for neutral and aggressive media * Media examples: Glycol, ferric chloride, hydrochloric acid, phosphoric acid, etc. * Two 1.5 V batteries (AAA) interchangeable Features & Advantages * Measurement according to the turbine wheel principle * Display of partial and total quantity * Variable display orientation * Mobile on a Drum pump or with nozzle connection * Measuring range from 5 l/min - 120 l/min * Easy battery change

Request for a quote

LUTZ PUMPEN GMBH

Germany

Piston diaphragm dosing pumps are particularly precise and pressure-independent dosing devices. The dosing quantity changes proportionally to the stroke length and can be set reproducibly down to the smallest quantities. For this reason, twin and multiple piston pumps are particularly suitable for precise mixing tasks in which a constant ratio of different media, which can be set as required, must be metered. The total quantity can be infinitely varied from 5% to 100% at a constant ratio using externally adjustable drive motors. Heated heads allow the dosing of cold, rigid media. An optional flushing lantern can be used to prevent harmful leaks and to protect the packings and pistons against abrasive substances.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The FEDOS E is the latest development in the FEDOS series, combining proven features with modern dosing technology requirements. It offers improved flexibility and efficiency in process engineering applications. Piston dosing pumps are robust and accurate, ideal for precise liquid dosing in various industries. Their simple mechanism ensures reliability and durability. Key features: . Precision: Accurate dosing . Robustness: Durable and resistant . Flexibility: Processes different liquids . Easy maintenance: Easy to maintain Piston dosing pumps are ideal for applications that require high accuracy and durability.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MAGDOS LB solenoid-driven diaphragm dosing pump is the cost-effective alternative for simple and continuous dosing tasks. It is particularly suitable for water treatment and the process industry. The MAGDOS LB is available in seven performance ranges so that it can be flexibly adapted to different requirements. Double ball valves ensure exact dosing, which enables precise and reliable control of the dosing quantity. The dosing capacity is infinitely adjustable via the stroke frequency of the dosing pump and can be set from 0 to 100%. The MAGDOS LB impresses with its compact design and is reduced to the most important elements for reliable dosing. This makes it not only space-saving, but also easy to operate and maintain.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MAGDOS LP solenoid-driven diaphragm dosing pump is the ideal solution for precise and reliable dosing tasks. It is available in seven different performance ranges and therefore offers flexible adaptation to different requirements. Thanks to the double ball valves, exact dosing is guaranteed, which ensures consistently precise results. The dosing capacity can be adjusted in a variety of ways: manually, via external control contacts or by means of a 0/4 - 20 mA signal. The MAGDOS LP is also available with an optional Ethernet interface. The stroke frequency and the number of strokes can be controlled via the network connection. In addition, all fault messages can be transmitted in the opposite direction, enabling optimum monitoring and control. The combination of flexible customisation options and state-of-the-art network technology makes the MAGDOS LP the perfect choice for a wide range of dosing applications.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MEMDOS LB solenoid-driven diaphragm dosing pump is the ideal solution for applications where the pump needs to be integrated into control systems or control loops. Thanks to its robust plunger drive and the option of manual or automatic capacity adjustment, the MEMDOS LB reliably and precisely doses various media such as acids, alkalis, precipitants and flocculants. The dosing capacity is adjusted either by mechanically adjusting the stroke length or by controlling the speed of the three-phase motor via a separate frequency converter. This flexibility enables precise control of the flow rate to meet different requirements. On request, the MEMDOS LB is also available with a double diaphragm system, which offers additional safety and reliability. This combination of versatile control and robust design makes the MEMDOS LB the ideal choice for demanding dosing tasks.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The diaphragm dosing pumps in the MEMDOS MR series have been developed for a wide range of applications in dosing technology. They are ideal for use in industry, process engineering, water treatment and waste water treatment. Features: . Robust dosing head: Made of PP and stainless steel for high durability and longevity. . Precise dosing: Double ball valves (up to MR 290) and spring-loaded flat-seat valves (from MR 290), optional spring-loaded single ball valves. . Safety: Separation chamber with drainage tube between dosing head and gearbox protects against leaks. . Flexible stroke adjustment: Can be adjusted manually or electrically (ATE). Optional extensions: . Dual dosing pumps for increased performance. . Stroke counting with inductive sensor for precise batch processes. . Frequency inverter control for variable control.

Request for a quoteFAUDI GMBH

Germany

Advantages Simple, compact design Area of application For the filtration of all types of liquids; protection filter for pumps and volume meters, pipeline filter, etc. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S8 Filter aid - Filtration degree 10 µm - 5 mm Medium Oil, water Filter material Sieve Disk

Request for a quote

SCHAAF TECHNOLOGIE GMBH

Germany

Sweet creamy fillings in a moulded, crisp extrudate shell The latest in sophisticated products from direct extrusion are the co-extruded, centre filled products. In these products a soft filling with a pumpable viscosity is metered continuously, using a suitable pump, into an extruded pipe, simultaneously while it is being extruded. A special design co-extrusion die is used for this purpose. The result is an extruded pipe filled with a creamy mass. This pipe can then be moulded into various shapes continuously with the help of special moulding rollers. Raw-materials: It is important to choose a proper combination of the extrudate raw-materials and the filling mass in these kinds of products to ensure that they combine harmoniously in the final product to give a compatible eating experience to the consumer.

Request for a quote

AIS HENSCH AUTOMATION-INDUSTRY- SOLUTIONS INH. IGOR HENSCH

Germany

Industrial pumps play a crucial role in a variety of industrial applications and are essential components for the efficient functioning of processes in various industries. At AIS Hensch Automation-Industry-Solution we offer a wide range of high quality industrial pumps designed for reliability, efficiency and performance. Versatility and Adaptability: Our range of industrial pumps includes a variety of types including centrifugal pumps, centrifugal pumps, metering pumps, screw pumps and more. These pumps are suitable for a wide range of applications, be it in the chemical industry, mining, food processing, water treatment or other industries. High-quality construction and materials: Our industrial pumps are made from robust materials and manufactured to the highest quality standards. They feature a durable construction that ensures reliable performance even under demanding operating conditions.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2500 Variospeed is a fully automated filling, foil application and sealing machine, suitable for creamy to liquid filling media for plastic, tin or glass containers. Available performance versions: 2.500 units/h, 3.000 units/h or 3.500 units/h. all gearboxes are maintenance-free: Lenze main drive, Atek gearbox, Miksch stepping gear various cams on drive shafts of the gearbox: filling cam, control cam for valves, pre-sealing cam, lever arm for driving the metering pump and dispenser drive shafts with prockets for chain drives central lubricating system 8-up turntable with mechanical overload clutch backlog detector and monitor for incoming and outgoing containers filling unit with turntable metering unit 40 liters filling funnel dispenser with pre-sealing thermal sealing unit (conductive) integrated conveyor belt central, stepless height adjustment of conveyors and guides by a handwheel integrated SPS control system Siemens S7

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE flow sensors without integrated Amplifier permit the space-saving flow measurement on site and the comfortable setting of the limit value using separate amplifier, e.g. within a control cabinet. The measurement takes place without mechanically moving parts using a thermal measuring element. The current flow state is displayed at the amplifier using LEDs. The sensor can be exposed to high temperatures. The devices are used wherever a safe, robust and low-maintenance monitoring of flow values is required. This includes e.g. cooling circuit monitoring, monitoring of the flow rate of process fluids, monitoring of metering processes or also for pump protection in process and factory automation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump hydraulically temperature controlled for a wide range of applications. This ranges from organic and inorganic chemicals to food oils, polymers and pharmaceutical products. A wide-ranging modular system provides optimum material combinations for corrosive or abrasive media.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Dosing pumps Dosing pumps are used in a wide range of applications, such as in the production of fibres. Synthetic man-made fibres are becoming increasingly important. They are needed for many different applications such as textiles, linen, bristles etc. WITTE metering pumps ensure that the polymer melt is delivered evenly and reliably to the appropriate points in the process. In order to guarantee a constant quality, a constant flow rate is very important. But also in other applications, media with very low viscosities can be pumped safely and precisely. High efficiency and a long service life are the hallmarks of this pump series.

Request for a quote

STRONG MAGNETS GMBH

Germany

Magnetic coupling is widely used in various fields such as magnetic drive of sealing vacuum of metering pump of polyurethane foamer, magnetic drive of pneumatic ball valve, magnetic drive of stirring reactor, etc. to prevent leakage of raw gas. Magnetic coupling is mostly used in high vacuum, high cleanliness, poisonous, corrosive, or harsh environment to transfer power from the driving shaft to the driven shaft. Because of the use of isolation seal sleeve, dynamic seal into static seal, zero leakage can be achieved.

Request for a quoteMPT DOSING GMBH

Germany

WPH webReady The pH/ORP on-line process controllers are designed for industrial, commercial, and municipal water treatment applications. The output configuration allows you to program up to four outputs in a variety of control modes. Select from on/off mechanical relays or pulse proportional control for direct connection to metering pumps. The easy-to-use menu format and pre-wired, pre-mounted panel system options make set-up and installation quick and simple. Integrated data logging is available to validate system performance. With a USB memory stick data and event logs that include electrode measurements, temperature and relay status can be extracted. Then download log files from the USB stick to a PC. Product features: Range of applications Select from pH or ORP measurements and from five output options. Use In-Range to control a solenoid valve to dump a batch treatment tank when measurement value is within limits, or program for Out-of-Range Alarm in waste treatment applica

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Centrifugal gas separator are among the best components in the protection of your flow measurement accuracy, both custody transfer applications as well as in everyday application process. Application For avoiding measuring errors and damage caused by foreign particles contained in the medium. Reliability • maintenance-free • complete emptying via outlet socket Special features • with automatic float-dearation device, level probe and controled magnatic valve or defined return to the process (orifice) • mandatory for fiscal metering with pump operation in Germany • Bopp & Reuther Messtechnik Centrifugal Gas Separators possess the EWG design approval and are approved for EWG primery approval for fiscal metering Flexibility • DN 25 to 400 • up to 20 mPa ·s • up to 25.000 l/min • up to PN 50

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The APG-process by HÜBERS permits short cycle times thanks to rapid gelation and demoulding with automatic opening and closing of the mould. During the gelling process, fresh material is supplied continuously to the mould under pressure in order to prevent cracks and voids and to compensate for the shrinkage of the material. The mould is held together by the clamping machine. The degassed material is injected into the APG mould directly from the static mixer. Shrinkage compensation is carried out by the HÜBERS metering pumps. One central mixing and metering system can serve several clamping machines. In this case each clamping machine has its own static mixer positioned directly in front of the mould and also has its own shrinkage compensation unit to maintain the pressure. The system is supplied via a ring line which requires no maintenance and is free of sedimentation. In principle the length of this line is insignificant.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2500 Variospeed is a fully automated filling, foil application and sealing machine, suitable for creamy to liquid filling media for plastic, tin or glass containers. Available performance versions: 2.500 units/h, 3.000 units/h or 3.500 units/h. • all gearboxes are maintenance-free: Lenze main drive, Atek gearbox, Miksch stepping gear • various cams on drive shafts of the gearbox: filling cam, control cam for valves, pre-sealing cam, lever arm for driving the metering pump and dispenser • drive shafts with prockets for chain drives • central lubricating system • 8-up turntable with mechanical overload clutch • backlog detector and monitor for incoming and outgoing containers • filling unit with turntable metering unit • 40 liters filling funnel • dispenser with pre-sealing • thermal sealing unit (conductive) • integrated conveyor belt • central, stepless height adjustment of conveyors and guides by a handwheel • integrated SPS control system Siemens S7

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function Emergency lubrication is a safety device which kicks in case of a complete failure of the power supply.It also ensures that the refiner main bearing is continually supplied with lubricant providing that the bearing is effectively protected against any damage due to inadequate lubrication.This retrofit unit mainly consists of one or more pumps, the flow meter and a drive unit for connection with the powertrain of the refiner. Advantages Protection against inadequate lubrication and severe bearing damage Reliable lubrication as long as the powertrain turns

Request for a quoteResults for

Metering pumps - Import exportNumber of results

26 ProductsCountries

Company type

Category

- Flow meters (7)

- Pumps (7)

- Gear pumps (4)

- Dosing pumps (2)

- Sensors (2)

- Electric and electronic components - machines for manufacturing (1)

- Magnets (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Package stamping machinery (1)

- Packing and packaging - machinery and equipment (1)