- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal stamping

Results for

Metal stamping - Import export

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Stampings (and stamped parts) are versatile and you find them in a wide range of applications for many different industries. Lesjöfors delivers stamped parts from our standard program as well as customized solutions.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

very flexible over three axes Stretch values up to >40%. high compression ratio

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Stretching up to 100 % possible very light version large variety of designs

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Single Spine / Einstegig extremely flexible over three axes predetermined breaking points can be defined Free choice of spine width and positioning Double Spine / Two-webbed reduced "hungry horse" effect predetermined breaking points can be defined Free choice of spine width and positioning

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

maximum weight reduction high design flexibility predetermined breaking points can be defined

Request for a quote

KARL NAUMANN GMBH

Germany

small selection from our production range for stamping

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our ACP Group offers over 400 different variants of stamped and lanced metal carriers. These carriers are used in a wide variety of sealing systems. Only high-quality raw materials such as steel, aluminium and stainless steel from certified suppliers are used for production. The Huehoco Group also offers a wide range of coating options. From functional to decorative coatings, our customers can choose from a wide range of products. We offer suitable bonding agents for almost all types of rubber and plastic compounds.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

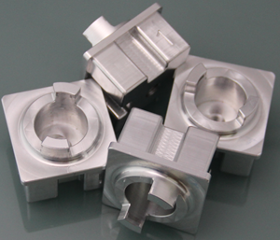

Mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quote

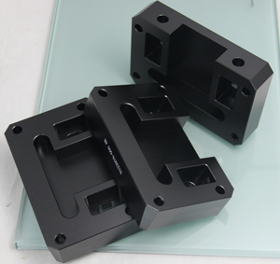

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quote

IGUS® GMBH

Germany

Solutions for plates Application examples - Automotive The new solution for all applications in stamped sheet metal retainers: iglidur® Clip On's are frequently used in seat and convertible top systems and multi-joint hinges. iglidur® clip-on bearings facilitate captive assembly even in punched sheetmetal / steering arms with limited fine blanking content. Compensation of axial clearance Loss secure pre-assembly possible Electrically conductive materials are optionally available Pressure-resistant materials until 80 MPa The Clip On bearings can also be produced from electrically conducting iglidur® RN89, thus permitting e-coating.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

We are specialized in the production of precision parts and assemblies for the medical technology, automotive, telecommunications, metrology and renewable energy industries. We use our own equipment and technologies and undertake in-house fixture construction. Laser machining, electrochemical metalworking and mechanical manufacturing are our core competencies. We manufacture quantities from 50,000 up to several million per year. You will find further information in brochure at our homepage.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The effective protection against self loosening and unscrewing. The "SK" Serrated Locking Washer prevents self-loosening of screwed joints. Damage to the bearing surfaces and consequent variations in the tightening torques, as they occur in threadlockers with teeth are avoided with lock washers through the special geometrical shape of the locking edges. shape S (small) shape M (middle) shape B (wide) shape Z (for screws with cylindrical head shape) shape K (for electrical contacts)

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The contact lock washer to NFE 25-511 and SN 70093 with grooved surface provides the designer the ability to secure wobble-prone screw effectively. It is particularly suitable for use on slot fasteners, dynamic cross-loaded to the screw connections and applications that require high biasing forces. Operational: The contact wheel ensures positively spring and a form-fitting locking. Form S = narrow - for small headrests Form M = average - for normal headrests Form B = wide - for large pressure transmission surfaces and slot fasteners Form K = serrated - for electrically conductive connections with contact teeth (SN 70093)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Through the process of briquetting, the value of residual metals can be increased considerably. The value of residual metals can be increased considerably. A further advantage is the recovery of expensive cutting fluids that can be pressed out of wet chips and then reused. When melting briquettes, combustion is significantly lower and results in a higher melting yield than with loose chips. Depending on the need, our briquette systems are equipped with hydraulic motors between 4 and 90 kW. They will achieve a specific pressure of up to 5,000 kg/cm². Suitable for aluminium, steel, cast iron, copper and many other metals Advantages: - Heavy reduction of volume, reducing storage and transportation costs - Recycling of expensive cooling lubricants - Recipients often pay a better price for loose millings - Minimal burn-off and increased glaze recovery thereby For throughput rates between 30 and 4,800 kg/hr.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Grinding chips are created by the grinding of metal components. It is a mixture of metal and corundum abrasion in combination with the cutting fl uids being used. By briquetting, the waste is reduced significantly and the briquettes possess a defi ned residual moisture. Thus, the disposal costs are reducedand depending upon the alloy, there is even the opportunity to sell the briquettes with a profit. In most cases, the expensive oil contained in the cutting fl uid can be reused. The briquetting system can already payoff for itself within less than 12 months by processing about 10 to 30 tons of the expensive oil contained in the cutting fl uid per year. Depending on the requirements, our briquetting systems for grinding chips are equipped with hydraulic motors ranging from 4kW to 22kW, and reach a specifi c pressure of up to 3,800 kg/cm². The throughput of the RUF briquetting systems - especially for grinding chips - range from 40 to 350 kg/h.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser produces highly precise presses for the metal forming industry, thus increasing productivity, quality, and lifetime and decreasing overall operating costs. ANDRITZ Kaiser has delivered more than 8,000 presses for numerous customers world wide, each different in its application. A large number of factors have to be taken into account when deciding on the right press: technical requirements from the product, expected productivity, technical requirements on the press line, integration into the existing production lines, fixed and running costs, process control, fast availability of maintenance/service, availability of spare parts – all these considerations influence mainly the total cost of ownership. Our press solutions are: Conventional high speed presses from 630 kN up to 4,000 kN Conventional stamping and deep drawing presses from 1,000 kN up to 8,000 kN Cutting presses from 1,600 kN up to 6,300 kN Heavy presses from 10,000 kN up to 25,000 kN Servo presses from...

Request for a quote

ECKOLD GMBH & CO. KG

Germany

With the ECKOLD insertion system, nuts, studs and bolts can be pressed into almost any material, especially in the automated production. The servo motor-driven system can be configurated for stationary or robot-guided use. This offer includes: Servo motor-driven insertion system • Insertion frame, throat of approx. 700 mm Stroke 150 mm Press force max. 58 kN Positioning accuracy +/- 0.02 mm Stroke speed max. 150 mm/s • Servo motor-driven • Feeding unit • Separator • Frame • Control cabinet incl. visualisation software ECKOLD VISU • Tool holders Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Domes produced with ECKOLD machines in automotive industry make sure that there is only a minimum offset between the securing screws and the surrounding metal. ECKOLD machines can produce two or even three domes in a single process. Our dome embossing machines are suitable for both single and double sheet steel or aluminium parts and come with a hydro-pneumatic or servo motor drive system. With our machines, domes can be embossed without preliminary holes (even when combined with final hole punching for a defined diameter). This offer includes: Dome embossing frame Embossings: 1 piece/stroke Embossing geometry: according to data set Drive: pneumohydraulic Mechanical interface: support stand Embossing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. We optionally offer hydraulic or servo motor drives as well as multiple embossings/stroke.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

In ultrasonic systems, the booster functions as a transmission tool to change the amplitude provided by the converter. It then forwards it to the sonotrode of the oscillating system. Depending on the design and installation direction, the amplitude can be reduced or increased by the booster. The booster is also suitable to embed the vibrating system into a machine if a clamping or tension ring is attached to it. soniKKs boosters stabilize the vibration behavior and ensure lossfree transmission through completely flat coupling surfaces. We usually manufacture our boosters from titanium. This material maintains its positive properties even at high temperatures. It has an exceptionally high corrosion resistance and belongs to the light metals. We are happy to match our boosters to your specific needs. Your Advantages “Made in Germany” Usually made of titanium Lossfree transmission due to optimally processed coupling surfaces Suitable for the food and pharmaceutical industry

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

In ultrasonic systems, the sonotrode transmits the mechanical vibration of the converter and booster to the relevant workpiece, thus completing the oscillation system. The sonotrode, just as the booster, can additionally increase or decrease the amplitude of the system through a corresponding geometry. Depending on your application and/or the material that needs to be processed, we can design the sonotrode in a way that optimal results will be achieved. soniKKs sonotrodes are usually made of highquality titanium or steel, which is also approved for aerospace. Titanium retains its positive properties even under high temperatures. It has an exceptionally high corrosion resistance and ranks among the light metals thanks to its light weight. We are happy to match our sonotrodes in terms of form and material to your specific needs. Your Advantages “Made in Germany” Made of highquality titanium or steel Suitable for the food and pharmaceutical industry Production of special shapes

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Ultrasonic converters, also called transducers or oscillators, convert highfrequency electrical voltage generated by ultrasonic generators into a mechanical vibration of the same frequency. The piezoelectric effect is used here. The ultrasonic converter forms the starting point of the oscillation system and transmits the vibration to the booster and sonotrode. Our soniKKs converters captivate with their compact design, reliability and durability. As all our products, they are also "Made in Germany". The resonant body is made of titanium or steel. We are also happy to manufacture special converters and housings according to your needs. Your Advantages “Made in Germany” Compact design High reliability, durability, and costeffectiveness Production of special converters/housings on request Resonance base body made of titanium or steel Also suitable for the food and pharmaceutical industry

Request for a quote

KRAMSKI GMBH

Germany

Compositing of stamped metal insert parts and plastic belongs to our core skills. With our know-how in both technologies, we are able to offer our customers projects and production that push the borders of what is technically possible, when synergistically compositing metal and plastic – and that from us as a single source.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

Technical plastic : Polyethylene (Short : PE) Product name Polyethylene (PE or sub groups like PE-HD, PE-LD, PE-HMW, PE-UHMW, PE 300, PE 500, PE 1000 or RCH 1000 and many more) Delivery form Sheets, cuts, milled products, base profiles Specification Polyethylene - technical plastic Polyethylene ( Short: PE ) is a technical plastic that can be processed easil. It has a density of about 0,95g/cm³ and with that it's the second least weighing plastic of all technical plastics and just because of that it offers a very interesting price. The moisture absorbtion of PE is about 0,0 %. The material is really good against lyes and acids , has a self-lubricating effect and is easy to mill ( cut, milling, lathe, water jet cutting and welding ). Furthermore it is a great material for abrasive fraught parts in e.g. machine engineering ( PE UHMW ), as inlay for bulk containers or as a cutting boards in the food industry or households. We would like to advise you which kind of PE RG ist the...

Request for a quoteResults for

Metal stamping - Import exportNumber of results

32 ProductsCountries

Company type

Category

- Stamping - steels and metals (12)

- Stamping - machine tools (5)

- Sheet metals - stamping (3)

- Milling - steels and metals (1)

- Bicycle frames (1)

- Embossing machine tools (1)

- Engineering - industrial contractors (1)

- Import-export - steels and metals (1)

- Mechanical transmission - components (1)

- Medical and surgical optics - instruments (1)

- Perforation of steels and metals (1)

- Valves for industrial fittings (1)

- Vehicles - mechanical components and parts (1)