- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal solutions

Results for

Metal solutions - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

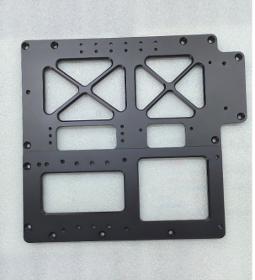

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The versatility and and capability of LAWECO products is most notably shown in coil processing systems. In the infeed and outfeed areas, coil lifting carriages primarily handle the coil. In conjunction with various rack systems even complete solutions can be realised. In the stack areas, stationary and movable scissor lift platforms provide the required handling. Here, it is also our goal to respond to the wishes and requirements of our customers and to provide individual solutions. Load bearing capacity up to 150 t Movable or stationary With simple, tandem or double scissor With materials handling technology or special constructions Mechanical coupling facility With powerful switching hydraulics or control valve technology With weighing device With positioning system

Request for a quote

MESUTRONIC GMBH

Germany

SPECIAL CONVEYING SYSTEMS TRANSTRON SERIES S / M / L / XL / CM / CL / CX CONVEYING OF PACKED PRODUCTS AND BULK MATERIALS IN THE PRODUCTION LINE WITH “METAL FREE AREA” FOR THE INTEGRATION OF METAL DETECTOR. High value tailored solutions. Reliable continuous operation. Guaranteed long-term, trouble-free metal detection results.

Request for a quote

MESUTRONIC GMBH

Germany

SPECIAL CONVEYING SYSTEMS CONVEYING OF PACKED AND BULK PRODUCTS IN THE PRODUCTION PROCESS WITH “METAL FREE AREA” FOR THE INTEGRATION OF METAL DETECTOR Budget sparing individualized solutions. Guaranteed long-term, trouble-free metal detection results. Continuous operation, reliable and with low maintenance. Systems available for nearly any application, from mill feeding over bag checking to the Transport of textile fibres.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP foremost engage with clients to build systems tailored towards their needs. Each tank is custom specified for each application, following a customer consultation – as construction materials, coatings and sealants differ greatly depending upon the stored media. Tank integrity, stability and corrosion resistance are paramount in any LIPP installation – which is achieved through a detailed understanding and advanced construction methods. This means water, aggressive liquids, solids, gaseous media and other substrates are provided for with equal expertise. Performance models and efficiency calculations also provide the customer with an insight into the future performance of their system. In terms of materials, LIPP provides the most appropriate metallic materials solution for each application. The entire spectrum is catered for; from specific purpose graded steels right up to high quality stainless steels.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIZERBA SE & CO. KG

Germany

Standard checkweighers with metal detector the inspection system for quality assurance at the highest level Bizerba's CWEmaxx series checkweighers with metal detector are used in the food industry mainly in middle- and high-performance settings. In the non-food area, they are used in lines with high output and wherever nominal weights up to 15 kg have to be checked. A built-in VARICON metal detector transforms the dynamic checkweigher CWEmaxx into a complete inspection system in compliance with HACCP, IFS, BRC and others. Verifiable combination units optimise quality assurance. They control the packaging flow by categorising and sorting goods by freely definable or legally stipulated weight classes. Checkweighers with metal detectors also check out of tolerance or contaminated packages and are automatically ejected. A combination checkweigher with metal detector is the ideal solution when space is at a premium, used with _connect.BRAIN the system will seamlessly integrate with...

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Matthews Marking Systems offers specialized inkjet and software solutions for the metal industry which can handle high temperatures, oily or dusty surfaces and changing material compositions. The MPERIA® V-Series enables clear marking on various materials and can be integrated into production systems. It is particularly suitable for machine builders and OEMs, with benefits such as specialty inks, low maintenance, high availability, robust design and flexible printhead mounting. Matthews' specialty inks are highly adhesive, fast drying and temperature resistant, ideal for aerospace and marine applications. The V-Series printheads are durable, low maintenance and enable automated cleaning processes. Large ink containers reduce maintenance cycles. The MPERIA® V-Series integrates into existing production lines and enables printing from different angles. Central control is provided by the MPERIA® universal controller, also in a version for harsh environments.

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET SC enables contact free printing of 1 to 8-line texts, dates, barcodes, Data Matrix codes and logos in high resolution, and with print heights up to 12 mm. The robust and stainless steel housing with IP54 protection class and the intuitive operation make this coding and marking solution suitable for smooth surfaces like foils, laminates and a very wide assortment of plastics and metals. Applications — Printing of variable data such as counter, date, time, shift code, best before date date, etc. — Serialized data for traceability — Bidirectional printing — Alphanumeric texts, barcodes, 2D codes — Ideally suited for smooth surfaces thanks to short drying time — Ideal even with larger distance to product surface — Suitable for high production and marking speeds

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

PFLITSCH offers various hoses to provide comprehensive protection against mechanical and thermal damage to cables, for example where cables are installed in a corrosive environment or where cables run across the floor between a machine and a mobile operating enclosure. The UNI Dicht® system has suitable solutions in metal and plastic for safe connection of hoses to cable glands in these situations. Clampless variants are most suitable e.g. for the food industry, where no contamination or dirt is allowed to build up. These variants have all the advantages of the UNI Dicht® system, including a excellent seal up to IP 68, superior strain relief values, EMC and Ex-compatibility as well as great versatility of application. Also available are cable glands for Smooth hoses Spring-stiffened UL hoses Hoses with external steel braid Availability in sizes from M6 to M120 and Pg 7 to Pg 29.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quoteResults for

Metal solutions - Import exportNumber of results

11 ProductsCountries

Company type

Category

- Chemistry, inorganic - raw materials and derivatives (1)

- Electric and electronic components - machines for manufacturing (1)

- Hoses, pipes and tubes - plastic (1)

- Measurement - Equipment & Instruments (1)

- Metal detectors (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Rolling machines (1)

- Tanks, metal (1)