- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal alloys

Results for

Metal alloys - Import export

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

pressure equipment: valves, boiler systems, piping PED 2014/68/EU, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering American Bureau of Shipping (ABS) Bureau Veritas (BV) Det Norske Veritas (DNV) Lloyds Register (LR) Nippon Kaiji Kyokai (ClassNK)

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Good compromise between alloy properties, lower metall cost and better scrap value assessment conditions. It has very good cold forming properties and a good conductivity combined with high strength and hardness.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Rapid developments in the fields of control engineering and in microprocessor and semiconductor technology have resulted in the widespread use of electronically controlled systems in every branch of industry today. This has created a need for sensors that are inexpensive but, at the same time, sufficiently robust, both electrically and mechanically, to withstand a wide range of temperatures (e.g. from -40 to +160 degrees centigrade), particularly in applications involving large quantities, such as the automobile industry. Fig. 1 provides a summary of the various types of sensors for angular and linear motion that are in use today. This paper is concerned with quality criteria (1) and (2) applicable to conductive-plastic potentiometers for use as sensors for angular and linear motion. Such potentiometers essentially comprise the following components: 1. The resistance element (support material + a resistance track of conductive plastic) 2. A wiper (precious metal alloy) 3. A...

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Almaredge 23 Water-miscible premium cooling lubricant Description Castrol Almaredge 23 is a chlorine-, formaldehyde-releasing and boron-free high-performance cooling lubricant. It contains an excellent additive package that improves machine performance and surface quality, ensures excellent stability and reduces machining costs . Castrol Almaredge 23 is suitable for both central systems and individual systems. Application Castrol Almaredge 23 is a versatile product and is used for general machining of low-alloy steels and aluminum alloys. Benefits -Boron-free to comply with health and safety regulations -Chlorine and nitrite-free to comply with waste treatment, workplace safety and environmental laws -Low foam at recommended water quality -Low fog at recommended water quality -Ability to process different metal alloys provides opportunity for product consolidation

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Almaredge 23 Water-miscible premium cooling lubricant Description Castrol Almaredge 23 is a chlorine-, formaldehyde-releasing and boron-free high-performance cooling lubricant. It contains an excellent additive package that improves machine performance and surface quality, ensures excellent stability and reduces machining costs . Castrol Almaredge 23 is suitable for both central systems and individual systems. Application Castrol Almaredge 23 is a versatile product and is used for general machining of low-alloy steels and aluminum alloys. Benefits -Boron-free to comply with health and safety regulations -Chlorine and nitrite-free to comply with waste treatment, workplace safety and environmental laws -Low foam at recommended water quality -Low fog at recommended water quality -Ability to process different metal alloys provides opportunity for product consolidation

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

With our delivery program “Screws for direct screwing” we deliver a great variety of thread rolling screws in different implementations. In doing so we realize small lot sizes and short-term delivery dates. Upon request we also introduce customer-oriented warehousing also in your company. Apart from the many advantages you can save time and money. We provide: KTG screws for thermoplastic materials: single pass thread or double pass thread (high/low); head shapes with cross or 6-star (similar Torx). Tapping screws: longitudinal slot, cross slot, cross-head-combination slot or 6-star (similar Torx). DIN 7981, 7982, 7983 or to the new ISO standards; special tip-styles, e.g. with with pressed washer. Combination screws with undetachably washers: According to DIN 6901. Self-tapping screws: According to DIN 7500. Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry...

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

NANOSYSTEC GMBH

Germany

Exactly tailored to the respective process requirements of the devices, VersaWeld provides high productivity from the beginning. The application determines which laser source will be used and thus stainless steel, Kovar, Titan alloys and nonferrous metals can be efficiently processed. Typical devices for precision laser welding include sensors, micromotors, medical components and other miniature elements such as housings which require leak tightness.

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Titanium alloys • Metals with high residual stress • Stainless steels • Special alloys • Abrasive non-ferrous metals and graphite

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== ZINC INGOT Usage: Mainly used for die-casting alloy battery industry Pharmaceutical / rubber industry Chemical industries zinc and other metal alloy plating coating industry in applied widely. Factory with strong supply ability silver white lustrous metal zinc ingot for die-casting alloy battery industry 1. mainly used for melting ingot 2. discontinuous melting with scrap 3. Used for industry such as automobile,pinning and weaving,electron broadly and so on

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microSTRUCT™ C is a highly flexible laser micromachining system predominantly used in product development and applied research. Superior flexibility makes the system ideally suited for laser structuring, cutting, drilling and welding applications on a variety of substrates, e.g. metals, alloys, transparent and biological material, ceramics and thin film compound systems. The microSTRUCT™ C offers a maximal degree of freedom regarding the positioning of the substrates. Flexible, stable and repeatable machining results Two independent and free configurable working areas with various optical setups Open system concept for the integration of different laser sources High range of software functions (Masterscript) User friendly, flexible, upgradeable system

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microPRO™ is an adaptable laser micromachining system mainly used in industrial production. Its high versatility makes the system perfectly suited for industrial laser micromachining tasks such as laser structuring, cutting, and drilling applications. Furthermore, it is suitable for a variety of materials, e.g., metals, alloys, transparent and biological substrates, ceramics, and thin film compound systems. The microPRO™ is available with an automatic handling system for wafers, cassettes, trays, etc The microPRO™ enables the laser processing of various substrates. Due to the integration of different technology modules, the platform can be adapted to customers’ requirements. Configuration packages may include High speed cutting Drilling Engraving Structuring and modification Laser Lift Off (LLO) Cylindrical machining Customized solutions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LECHMANN ENGINEERING GMBH

Germany

With our saws and profile processing centers, we are able to precisely cut sheet metal and profiles on request. Elumatec DG244 double miter saw for lengths of up to 6000 mm, high-quality cutting of profiles made of aluminium, PVC and light metal alloys. Cutting profiles made of aluminium, PVC and non-ferrous metals with our SBZ-151 5-axis profile machining center from Elumatec.

Request for a quote

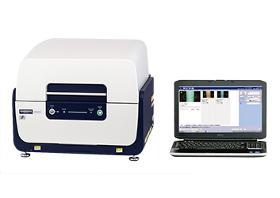

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

With this high-end spectrometer the advantages of a fast and precise 50mm2 SDD, a flexible and robust X-Ray excitation and a motorized XYZ-stage can be used to analyse a wide range of samples in fast, reliable and precise measurements. This includes for example (but not restricted to): - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder A Dual CCD camera system with wide view and high-magnification view enables a precise positioning of the sample easily from a big area to investigate exactly to region of interest you want to analyse. With the help of the optical system an easy navigation over the sample is possible and a laser-based auto-focus system ensures correct measurement position. Furthermore a second laser-system prevents collisions. The easy identification of areas containing targeted elements is possible by combi

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

The use of XRF techniques enables a non-destructive analysis of nearly all kind of samples with almost no pre-processing. Already this basic spectrometer configuration allows you to analyse: - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder with respect to the latest restricted materials guidelines (like RoHS, WEEE, etc.) but also in a more general way to estimate the composition in an element range from Al (13) to U (92). A CCD camera is used to position the sample that only the area of interest is measured – with the use of suitable collimators a minimum spot size of 1mm can be realized. To enhance the measurement speed and analytical performance (energy resolution) the EA1000VX is equipped with a state-of-the-art 50mm2 SDD detector (no liquid Nitrogen needed anymore). This hardware allows you to analyse film thickness

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

Coating with a FreiLacke electrodeposition coating (EC) is the economical and environmentally-friendly method of protecting and embellishing metal substrates. The procedure is principally suitable for all conductive metals and alloys. The component to be coated can be connected either as a cathode (cathodic electrodeposition coating) or as an anode. Electrodeposition coating as a method of corrosion protection is used in the automotive industry as well as many other sectors. The EC method enables process recycling and can be fully automated. Ranging from heaters to switch cabinets and shelves – FreiLacke electrodeposition coatings give surfaces great mechanical strength and are ideal for customer-specific developments.

Request for a quoteResults for

Metal alloys - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Lubricants, industrial (3)

- Hand tools, non-power (2)

- Laser - cutting and welding machines (2)

- Screws (2)

- Steel & Metals (1)

- Copper and copper alloys (1)

- Steels and metals - machining (1)

- Automobiles (1)

- Forming - steels and metals (1)

- Import-export - electrical and electronic equipment (1)

- Offshore construction (1)

- Paints and varnishes (1)

- Sawing machine tools (1)

- Smelting furnaces (1)

- Zinc and zinc alloys (1)