- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- medium-viscosity

Results for

Medium-viscosity - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The innovative precision-volume-dispenser eco-PEN700 made by ViscoTec offers a wide range of applications for low to medium-viscosity dispensing. preeflow® eco-PEN is a rotating and perfectly pressure-tight displacement system. Self-sealing rotor/stator design. Conveyance action by medium displacement in the stator through controlled rotor rotation. Safe conveyance without any modification of the medium. With its suck back option, preeflow® ensures clean and controlled material or medium cut-off while preventing post-dripping effects.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The precision volume dosing unit eco-PEN600, made by ViscoTec, enables many applications in the low to medium viscosity dispensing range. It is ideal for dosing grease, paint, sealants, adhesives, oil, silicone, generally abrasive media and many other materials. The preeflow® eco-PEN is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping.

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple Sieve Cylinders enables a large filtration area on limited space Higher filtration degree possible through bag inserts Area of application Applicable as pipeline and process filter Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S26 Filter aid - Filtration degree 0,5 µm - 20 mm Medium low viscosity liquids, gases Filter material perforated plate cylinder, mesh, bags

Request for a quote

LUTZ PUMPEN GMBH

Germany

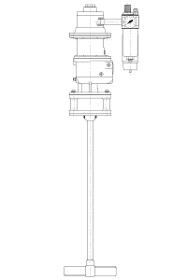

Eccentric screw pump tube HD-E Industryfor oils, paints and disposal liquids is available in the food version (Pure) The HD-E Eccentric screw pump in the industrial version transfers the advantages of the Drum pump low-viscosity media quite simply to the medium-viscosity range. The positive displacement pump has an easily detachable outer tube, a bearing head with mechanical seal and a free-running shaft with an eccentric screw as the pumping element - all easy to dismantle and clean. The Pump tube can be suitably combined with our single-phase motor. This ensures the draining of liquids and thus saves important resources. * also available in special immersion depths * Pump tube equipped with Lutz original hand wheel * Media examples: Oils, waste oils, disposal liquids, paints. * Smooth running * Uniform volume flow * Gentle, low-pulsation product conveying * Low wear * Easily detachable outer tube

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The precision volume dosing unit eco-PEN450, made by ViscoTec, enables many applications in the low to medium viscosity dispensing range. It is ideal for dosing grease, paint, sealants, adhesives, oil, silicone, generally abrasive media and many other materials. The preeflow® eco-PEN is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. Application: - point dosing, with highest volumetric accuracy - bead application with application speed adjustable to the web speed - Potting technology Your advantages: - True volumetric dosing - Retreat effect

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

It is possible to use all fluid lubricants through to grease, depending on their viscosity. The medium spreads evenly across the entire width of the roller so that it is possible to guarantee it is applied homogeneously at all times.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Eccentric screw pump B70V-D in PURE design is a powerful positive displacement pump for medium, high viscosity and viscous media up to the limits of flowability. Depending on the application, you can choose from a range of different rotary current motors, which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources. * also available in special immersion depths * Media examples: viscous cosmetic products, food and etc. Features & Advantages * Uniform volume flow * Easy and fast cleaning * Gentle, low-pulsation product conveying * Smooth running and low wear * Large selection of robust and powerful drive motors * Approved according to ATEX Directive 2014/34/EU, Category 1/2 * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C .

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRP - Pneumatic agitator GRP – pneumatic agitator The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. ((Infotexte)) Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0. The GRP is a pneumatic agitator...

Request for a quote

BDSENSORS GMBH

Germany

The stainless steel probe LMK 382H has been designed for continous level measurement in waste water, waste and higher viscosity mediums. Basic element is a robust and high overpressure capable capacitive ceramic sensor e.g. for low levels. Features: — nominal pressure range 0 ... 60 cmH2O up to 0 ... 200 mH2O — accuracy: 0.1 % FSO — diameter 39.5 mm — HART®-communication (setting of offset, span and damping) — permissible temperatures up to 85 °C — high overpressure capability — high long term stability Optional Features: — IS-version Ex ia = intrinsically safe for gas and dust — mounting with stainless steel pipe — flange version — diaphragm pure ceramic (99.9 % AI2O3) — accessoires e.g. assembling and probe flange, mounting clamp

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.) —Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc. — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy — Heated versions available (electrical, hot water, thermal oil, etc.) Power range - Different Versions 1 - 1000 dm³/h 50 - 5000 dm³/h 100-10000 dm³/h

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The CHEM gear pump series was developed especially for the requirements of the chemical industry. The series is used for pumping and transferring low to medium viscosity media. The CHEM series is extremely flexible in its design and areas of application. Technical details: — Suction pressures from vacuum up to 15 bar and suction pressures with magnetic coupling up to 25 bar — Delivery volume 1.28 cc/rev to 12,000 cc/rev — Temperatures up to 300 degrees — As special pumps for the chemical industry according to customer specifications — Viscosities up to 1.000.000 mPas

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

EXTRU - Melt pump for extrusion and pressure increase of medium to high viscosity media. The extrusion gear pump is mainly used in combination with extruders or kneaders. It reduces the natural pulsation of the extruder and compensates for fluctuations in delivery, especially in single screw extruders. The extrusion pump is used as a melt pump. It builds up the required feed pressure, which is needed for the downstream die. The pressure build-up in the gear pump can be much more efficient than in the extruder itself. The extruder is relieved by using an extrusion pump. Furthermore, considerably less energy or heat is introduced into the polymer. The melt pump thus contributes to conveying the product as gently as possible. The EXTRU is indispensable for the production of precise films or micro pellets.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

WHITE STEEL GMBH

Germany

1 to 3 molding heads Double Spindle Design For gentle products transport Diaphragm adjustable from 10mm. up to 9cm CIP System A vacuum equipped to avoid production interruption or product damage. Conical Feeding system Productivity starts from 8000 pcs/hr. up to 24000 pcs/hr Easy to use electric control panel Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Medium-viscosity - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Dosing - machines and equipment (3)

- Dosing pumps (3)

- Gear pumps (3)

- Pumps (2)

- Bottling and filling - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Dairies - machinery and equipment (1)

- Measurement and control instruments (1)

- Measurement and regulation equipment and instruments - output and flow (1)