- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical welding

Results for

Mechanical welding - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Turned parts with mechanical finishing. Ground, hardened, welded, soldered. Pre-assembled with sealing elements and O-rings.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

As mechanical connection elements, weld-on sockets are used wherever screw connections for measuring points need to be created quickly, reliably and economically. Along with standard weld-on sockets which is supplied in 1.4301 material, on request other materials such as special steels and alloys can also be used.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides their own clamp-band designs Freek also manufactures original Rosemount clamp-bands that can be used as "Husky-replacement heaters" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Freek has all the various industry standards for clamp-band nozzle heaters in Ø19,05 and Ø22,40 in their assortment, too. HotCoil minitubular heaters with clamp band are a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Especially for high-cavity PET plastic injection moulding there are various industry standards of clamp-band nozzle heaters available. Most common are the Axial Clamp-Band Heater and the Two-screw Clamp-Band Heater. Our HotCoil cable heaters with clamp band represent a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

New employees are first introduced to TIG welding in a basic training lasting several months. Only then are the first products manufactured for customers, whereby the following topics are handled in a multi-year development process, which includes the welding test for the tube welder CrNi relatively early: Material requisition Additional materials Gas protection Interpass temperature and welding temperature Maximum material temperature during welding Cleaning the weld seam Welding distortion Mechanical seam load

Request for a quote

ALPHA LASER GMBH

Germany

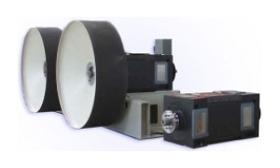

AL-SWS - the multifunctional laser workstation with variable table inserts for sensor production With this flexible laser machine you can effortlessly weld and cut even the smallest workpieces up to 12 mm in diameter, either automatically or manually. This laser system is mainly used in sensor production and in medical technology, for example for the production of jacket-insulated cables, sensors, resistance thermometers and thermocouples. Depending on the desired application, five different, interchangeable table inserts are available. These can be changed in a matter of seconds so that you can easily switch between the following welding or cutting tasks: Contact welding Circular welding Micro welding To cut Mantle welding under mechanical pressure

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

COMBER Pharmadry® - Series PH 50 - PH 4000 The Pharmadry vacuum paddle dryer with short drying times is well suited for the drying of freely flowing, sensitive pharmaceutical ingredients and fine chemicals. Designed to meet stringent cGMP and FDA guidelines. Special properties for the customer’s benefit: In compliance with cGMP and FDA guidelines, also in aseptic/ steam sterilizable versions Agitator supported at the rear, with externally exchangeable mechanical seal Entirely welded agitator design, without any bolts, without pockets and with all edges rounded for good cleanability Minimal build depth, thus very good accessibility for inspection and cleaning purposes Excellent cleanability using CIP systems, simple validation Available with separating wall between process and mechanical areas Double mechanical seal, externally interchangeable, dry running contacting or non-contacting lift-off type seals as well as liquid lubricated seals

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

The top tier of aesthetic and technology: With their flawless welding seams and trademark look, the KASPAR SCHULZ tanks are convincing in every aspect of brewery plant manufacturing. Thanks to our in-house only production, we can offer you customized plans that precisely tailor the tank measurements to the room height in your facility. The tanks are suitable for all types of beer, plus carbonated non-alcoholic and mixed beverages given that they are principally manufactured for a 3 bar operating pressure Ideal cleanup thanks to rounded manholes Temperature measurement using a contact sensor The bung apparatus (pressure regulator) can be integrated into the tank cleaning circuit without disassembly Welded and ground surfaces create an attractive appearance All piping is mounted mechanically (thus, without a welding arc). Piping is curved and therefore meets the highest biological safeguard requirements Minimal installation costs thanks to pre-piping

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, casing made of nickel-chromium steel 1.4571 Procurement of materials Welding Mechanical engineering Surface treatment

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Overhead cooling units for rail bound vehicles Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Assembly Test run Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Vehicle safety test equipment Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

The machine is manufactured in FMS’ production facilities and assembled at the end client’s site, including Mechanical and control systems design Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Internal assembly Test run at FMS’ facilities Assembly including hydraulics, pneumatics and electronics Control systems

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

Casing made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

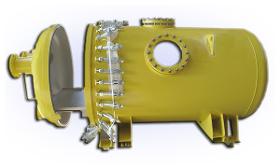

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

We support you throughout your design process and consider all the necessary technical requirements for welding. We can also produce components and assemblies from scratch. METZEN supports you with everything from purchasing materials to welding, mechanics, required checks and authorisations, surface treatment and, finally, documentation. Our product range includes normal steel vessel construction, stainless steel vessel construction/stainless steel pressurised vessel construction and aluminium vessel construction.

Request for a quoteResults for

Mechanical welding - Import exportNumber of results

22 ProductsCountries

Category

- Machinery and equipment, used and reconditioned (5)

- Supply vessels (3)

- Laser - cutting and welding machines (2)

- Flanges (2)

- Steels and metals - welding and brazing (1)

- Automation - systems and equipment (1)

- Casting, steel (1)

- Electroheat - machines and equipment (1)

- Elements, electric (1)

- Fittings, metal (1)

- Vacuum cleaners - industrial (1)

- Vehicles - mechanical components and parts (1)

- Wine fermentation tanks (1)