- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical treatment

Results for

Mechanical treatment - Import export

WALTHER TROWAL GMBH&CO.KG

Germany

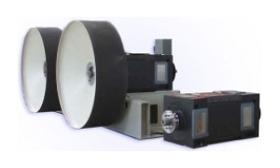

THE EFFICIENT SOLUTION FOR SMALL PRODUCTION SERIESAre you looking for a solution that is a more economical choice than a larger Trowal system? Then look no further than our E5 mini barrel. It is perfect for deburring and abrasion, above all on small workpieces from the optical and fine mechanics industries. The double-conically shaped rotating barrel body generates an intense rotation to achieve the perfect abrasion result. SOPHISTICATED TECHNOLOGY The mini barrel stands on a steel sheet construction with four pedestals. The barrel bodies are secured to a drive roller and support roller with locking rings. The barrel body is made from polyurethane and the quick-action cap is waterproof. SPECIAL EQUIPMENT It is also possible to attach two additional barrel bodies if necessary. These are driven via a roller system that is fully variable thanks to a three-phase motor. The cover can also be ordered with safety switches.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, casing made of nickel-chromium steel 1.4571 Procurement of materials Welding Mechanical engineering Surface treatment

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Overhead cooling units for rail bound vehicles Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Assembly Test run Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Vehicle safety test equipment Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

For assembling and connecting transfer lines Welding – major suitability certificate required Mechanical engineering Surface treatment Preassembly at FMS’ facilities including regulation and control systems On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

The machine is manufactured in FMS’ production facilities and assembled at the end client’s site, including Mechanical and control systems design Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Internal assembly Test run at FMS’ facilities Assembly including hydraulics, pneumatics and electronics Control systems

Request for a quote

METZEN INDUSTRIES GMBH

Germany

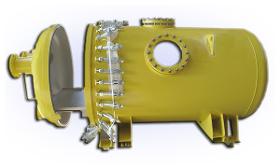

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

The compact electrode housings of our treatment stations are used for the reliable extraction of the ozone created by the corona treatment. Exhaust monitoring is an integral part of all corona stations and ensures that a corona discharge can not be activated without suction. The ozone is extracted by a pipe work and discharged to a safe height into the external atmosphere. To reduce the ozone load of the ambient air and comply with local environmental and health and safety regulations the extracted air can be passed directly into an ozone catalyser. Our ozone catalyser is a high performance filter unit designed specifically for ozone destruction in Corona treatment. Since ozone is extremely corrosive, all materials and seals used are corrosion resistant. The housing and all internals are made from corrosion resistant stainless steel. For reliable treatment of the exhaust air, three filter stages are contained within the housing.

Request for a quote

OTEC PRÄZISIONSFINISH GMBH

Germany

CF disc finishing systems with Siemens touch panel for setting and storing all main process parameters.

Request for a quote

HÜPPE GMBH

Germany

HÜPPE surface coatings. Quality through experience. We refine your products at the highest level. Powder coatings and wet coatings, sustainable and environmentally friendly, professionally according to the latest standards. We also offer our coating expertise in a wide variety of areas for your parts and assemblies. Our specialty is to paint design surfaces as technical coatings or surfaces according to customer requirements. Flawless results require know-how, experience and passion for the details. We paint parts and assemblies of all kinds for our customers. In addition to the standard RAL colors, we are also happy to implement special solutions such as special color requests, surface effects or different degrees of gloss. HÜPPE has the perfect solution for you. HÜPPE is your expert for the best possible surface quality with the longest durability. In addition to series coatings, HÜPPE also specializes in one-off production. Automatic and manual systems are available for this.

Request for a quoteResults for

Mechanical treatment - Import exportNumber of results

12 ProductsCountries

Company type