- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical testing

Results for

Mechanical testing - Import export

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quote

MERECS ENGINEERING GMBH

Germany

We plan, build and deliver turnkey test systems for electronic and mechanical components. For example, these are test benches for quality assurance, validation and production departments of companies in various industries. Our services include e.g.: - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design - Risk assessment and CE - Commissioning, service, maintenance at home and abroad

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

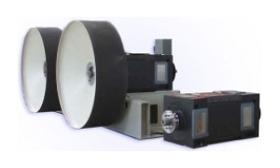

MOOG GAT GMBH

Germany

GAT torsion motors are supplied as individual components or as complete torsion system consisting of torsion motor unit, application-specific control electronic s and hydraulic supply. Comprehensive consultation services from concept planning phase to commissioning complement our portfolio. GAT torsion motors consisting of a basic motor and a GAT rotary union are designed for quasi-static, pulsating and dynamic loads. Speed and torque as testing parameters are controlled independently. The torsion test rig with mechanical torsion application allows the energy-efficient testing of components at relatively low investment costs. Using a hydrostatic torsion motor in the test rig creates realistic and consistent testing conditions leading to test results very close to real-life conditions.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

We have been manufacturing UP machines / components and beam delivery systems for over 20 years.Benefit from our experience and let us do your demanding assembly or adjustment work.Assembly / adjustment of optical systemsAssembly / adjustment of mechanical precision systems.cleaning.Clean room assembly.Functional test.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Essential for direct reading and high-capacity torque wrench calibration! Mechanical loaders increase the accuracy ot torque test results while simultaneously reducing technician fatigue from pulling or pushing on torque wrenches during testing. A mechanical loader is the perfect accessory to increase the repeatability and productivity of the System 5 Digital Torque Tester. The drive system for each loader assures true 90-degree force application to eliminate force angle error in testing. In addition, the loaders mechanical advantage reduces technician effort and fatigue, particularly in high-capacity tool testing. SR Mechanical Loaders use the highest quality ball screws to assure smooth operation and extended service life. Welded steel frames and rigid transducer mounting plates assure torque load is properly resisted. Optimized gearing selection reduces physical effort to operate, enhancing productivity and ergonomic safety.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

High-precision pressure sensors from the 8201 series provide exact measurements while exhibiting very little sensitivity to mechanical stresses. Their application therefore goes well beyond research and development laboratories. They are also outstandingly suited to industrial use in quality assurance or for measurement and control tasks in production. Their robust mechanical and electrical construction guarantees good long-term stability and high reliability, while being resistant to aggressive media – which can be measured in liquid or gaseous states. The structure of the sensors includes no mechanical moving parts, which is why they show so little sensitivity to impact and vibration. The pressure sensors can be configured with options to suit the user. Standard types are available ex-stock, and customized customer versions can also be provided. Aeras of application are: —Research and developmemt —Test rigs —Mechanical engineering —Plant control and monitoring

Request for a quote

TAVRIDA ELECTRIC

Germany

Challenge To execute a pilot project at the Energisa distribution network operator in Brazil within a tight time frame. The customer needed to install 23 kV outdoor circuit breakers with protection at a newly erected substation. Solution Tavrida Electric supplied the Rec25 with substation mounting kit to meet the deadline and satisfy the customer’s requirements in terms of protection. The mounting kit was subjected to comprehensive mechanical tests including overweighting, wind load and seismic impact with successful results.

Request for a quote

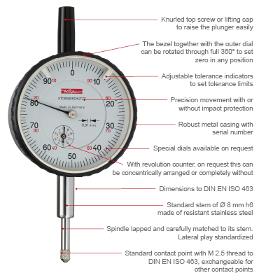

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The well thought-out design, accurate components and robust construction of our Precision Dial Gauge series offer reliability, durability and long working life. The standard features that enhance the quality across our entire product range are: Calibrations of all Dial Gauges are traceable to national and international standards. The final quality control for the whole series includes visual inspection and full mechanical functional tests. Supplied with Declaration of Conformity and Confirmation of Traceability. Materials and components selected specifically to ensure a long working life.

Request for a quote

ZANDER GMBH

Germany

Almost all automation solutions are provided with electronic or electronic computer-aided control. An important element in the implementation of your requirements are Programmable Logic Controllers (PLCs). Automation Technology / Electronics: We manufacture the necessary control for your application from project planning, production, programming to service. Configuration: Analysis of the control process Working out the tax concept Drawing and documentation creation by certified electrical engineers with EPlan P8 Optimal component selection Programming: Programmable logic controllers Industrial PC / bus and network systems Operating and visualization systems Remote maintenance systems cabinet mechanical machining Structure / wiring Testing and measurement Machine installation: wiring Connection of sensors and actuators commissioning Handover and service Service: overhaul software change revision

Request for a quote

TEST GMBH

Germany

Universal Testing Machine for methodical component and materials testing for forces up to 100 kN. Fields of applications are everyday industrial procedures in rough environments as well as in laboratories, in the fields of research and development or teaching. This technically mature product for static tests with modern measurement and control technology, the suitable right accessory and the innovative testing software TesTWinner® meets all requirements of modern material testing. In addition the model is equipped with the TesTController 850. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes, and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

The testing machines of model series 215 were developed and built for applications with extremely small measuring ranges, below 0.1 Ncm, and highest precision. They are for example used in watch idustry or medical technology. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

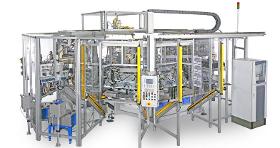

HOCHRAINER GMBH

Germany

Rotary indexing assembly table for power window mechanism including testing station .

Request for a quote

HEXPOL TPE GMBH

Germany

Representative Mediprene grades have been sterilized via: Ethylene oxide (EtO) Gamma Irradiation Steam / Autoclave Test Specimens for tensile tests were punched out of injection-moulded plaques. All mechanical test values refer to tensile testing of the material parallel with the flow direction. Changes reported have been calculated by comparing values for sterilized specimens with the corresponding values for the unsterilized reference. A guide detailing the test results is available to download here Investigation shows that EtO is the most gentle sterilization method for Mediprene TPEs.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Procurement of all materials Welding Full dimension check Mechanical engineering Pressure testing Leak testing with vacuum Surface treatment Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Busbar and circuit breaker vessel and containers in various designs Welding Full dimension check Mechanical engineering Pressure testing Leak testing with SF6 gas Documentation Acceptance

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

Due to their design, Vibrophores have been used in the past solely as dynamic materials testing machines to determine durability with regard to fatigue life and fatigue limit, for example for fatigue testing to DIN 50100 (S-N curve) under tensile, compression, pulsating and alternating loads. The new generation of ZwickRoell Vibrophores can be used as both dynamic and full-fledged static materials testing machines that accommodate test loads up to 1000 kN. Typical applications are material fatigue tests and durability tests on standardized specimens and components (for example, piston rods, crankshafts, and screws) and production and quality control of components exposed to dynamic loads during their service lives, such as concrete and reinforcing steel, as well as quasi-static tensile and compression tests and fracture mechanics tests on CT and SEB specimens.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

Fittings made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Casing made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Vehicle safety test equipment Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quote

SP SÜDDEUTSCHE PRÜFANLAGEN GMBH

Germany

For measuring mechanical properties of metallic materials

Request for a quoteResults for

Mechanical testing - Import exportNumber of results

23 ProductsCountries

Category

- Machinery and equipment, used and reconditioned (3)

- Supply vessels (3)

- Testing of products and materials (2)

- Flanges (2)

- Testing equipment (1)

- Calibration equipment (1)

- Electric transformers, converters and rectifiers (1)

- Electrical & Electronic Components (1)

- Foundries - machinery and installations (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission systems and components (1)

- Sensors (1)

- Vehicles - mechanical components and parts (1)