- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical solution

Results for

Mechanical solution - Import export

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNO-COMPOSITES DOMINE GMBH

Germany

Corner and plugin profiles and seat support covers TC products aren’t always apparent at first glance. They often resolve problems in complex assemblies. For instance, they are used to meet the need for a component that has good thermal insulation properties, but is also lightweight and has a high mechanical load capacity. Providing solutions with composite materials Lightweight yet high rigidity and strength Good thermal insulation Freedom in design for customised shapes Highquality, paintable surfaces Undercuts can be created in the profile Universal for radio waves

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

We provide complete mechanical engineering solutions: Whether you want to modify or upgrade existing systems, optimise manufacturing processes or automate your production: Our expertise in mechanical engineering enables us to come up with the ideal solution for you. We support you throughout the entire production process - even as your system partner if you wish: We listen to your ideas; we draw, design, engineer, build and even surface finish the new product that is destined to go into service as a machine, jig or tool at your site. We have clear organisational structures and work processes: Our qualified staff, who not only have many years of experience, but also undergo continuous training to ensure that they are always up to date, ensure that everything runs smoothly. We have a high degree of vertical integration and manufacture everything under one roof – that's also the reason we can react quickly and flexibly to any change requests you may have.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik has already become many customers' system partner of choice We provide complete mechanical engineering solutions: Whether you want to modify or upgrade existing systems, optimise manufacturing processes or automate your production: Our expertise in mechanical engineering enables us to come up with the ideal solution for you. We support you throughout the entire production process - even as your system partner if you wish: We listen to your ideas; we draw, design, engineer, build and even surface finish the new product that is destined to go into service as a machine, jig or tool at your site. We have clear organisational structures and work processes: Our qualified staff, who not only have many years of experience, but also undergo continuous training to ensure that they are always up to date, ensure that everything runs smoothly.

Request for a quote

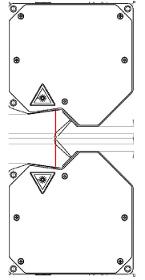

BERNSTEIN AG

Germany

The aluminium control enclosure CC-5000 neXt offers a unique design with a number of accessories such as the status light. The rounded contours ensure the enclosure is highly recognisable in machinery and mechanical engineering applications. — Customised solutions to your specifications — Innovative and modern industrial design — Freely selectable width and height (max. 1.000 x 1.000 mm) — Depths from 75 mm up to max. 370 mm — Rounded edges, no risk of physical injury — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Optimum heat dissipation due to aluminium sections — Integrated recessed grips for simple handling — Protection class IP65 — Internally-mounted front panel — Door configurations for direct access to the interior — Slimline design for configuring flat screen systems

Request for a quote

SERVOLIFT GMBH

Germany

Bin lifters from SERVOLIFT are adapted to your bin types. Its modular construction provides for functional extensions by combining special installed components and process machines. One can develop an optimal, ergonomic system solution when using the bin lifters in combination with Servolift containers. Universal handling of all bin types Technical description Stainless steel - or cGMP-compliant designs High flexibility, such as for containers of any dimension and design High load range Stationary or mobile design Floor/ceiling-installed, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Wide range of control designs, from simple, direct manual lever controls up to PLC-controlled sequences Integration of product controls, such as installation of dosing units Pick up of containers, including discharge aid and valve actuators Extensive take-up and clamp systems, container holding device, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

Working with and handling drums is done all the time in the pharmaceutical, chemical and food industries. That is why efficient drum handling is a must, and needed in order to optimally structure operational processes. Our products help you with this and offer you a variety of opportunities. Efficient drum handling for drums of any diameter and material Technical description Stainless steel or cGMP-compliant designs High flexibility, such as for drums with any dimensions and of any design No load limitation Tilting function: lengthwise or cross-wise to the column Stationary or mobile designs Floor/ceiling-mounted, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Extensive series of control designs, from simple direct manual lever controls up to PLC-controlled sequences Various take-up and clamping systems such as a manual clamping ring, motor-driven clamp system, squeeze funnel clamp, fork shaped spears, special designs depending...

Request for a quote

IBK WIESEHAHN GMBH

Germany

Plant construction requires compensation of thermal and mechanical expansion. Our solutions are just as varied as the wide range of applications. Why not make use of our long years of experience? We provide assistance in both word and deed, calculate the technical design and give you individual advice – also on site. Applications: Power stations, major plants, blast furnaces, domestic installations, shipbuilding, chemical and food production plants, paper industry, engine systems, ventilation construction, sewage systems, material moving systems, silencing applications Nominal widths: DN 20 to DN 5000 Structural lengths: Varying standard structural lengths or custom production Connection types: - Flanges: RSt 37-2 blue chromated or stainless steel – other materials on request - Clamp fastening

Request for a quote

IBK WIESEHAHN GMBH

Germany

Plant construction requires compensation of thermal and mechanical expansion. Our solutions are just as varied as the wide range of applications. Why not make use of our long years of experience? We provide assistance in both word and deed, calculate the technical design and give you individual advice – also on site. Axial Compensators simple method of compensating for expansion | most space-saving method | no change in direction of flow Advantages - simple method of compensating for expansion - most space-saving method - no change in direction of flow Lateral Compensator compensate for all movements in one plane | reduce the load on all fixed points Advantages - compensate for all movements in one plane - reduce the load on all fixed points Angular Compensators compensate for all movements almost without limit | reduce the load at all fixed points Advantages - compensate for all movements almost without limit - reduce the load at all fi xed points

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

To achieve perfect induction heating processes depends on generators providing precisely the right amount of energy. With its CUSTOM LINE LF generators, eldec provides just the right solution for the low frequency range (2 to 8 kHz). Induction heating with tough generators “Customized” is the key word when it comes to delivering a perfect production solution in mechanical and systems engineering. This is particularly true for induction heating. The process needs to be configured accurately to produce the desired effect in the material. CUSTOM LINE generators by eldec are the ideal solution for delivering precisely the right amount of power and energy. The LF series (power: 50 to 500 kW, frequency: 2 to 8 kHz) is designed for lower frequencies.

Request for a quoteResults for

Mechanical solution - Import exportNumber of results

15 ProductsCountries

Company type

Category

- Compensators (2)

- Gears (2)

- Mechanical transmission - components (2)

- Control panels - electric (1)

- Energy - renewable (1)

- Gas turbines (1)

- Induction heating systems (1)

- Milling - steels and metals (1)

- Optical instruments (1)

- Optical measuring equipment (1)

- Pinions (1)

- Profiled sheets - ferrous metal (1)

- Sawmills - machinery and equipment (1)

- Steam turbines (1)

- Toothed wheels (1)

- Turbines (1)