- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded plates

Results for

Welded plates - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used for mechanical .

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigreen Aluminium Planter for installation outdoors on roof areas or in earthbound open spaces and for installation indoors. Planter made from aluminium in standard and custom sizes with overflow, insulating cladding, and, where required, with welded junction plates as reinforcement. On request, available with automated irrigation unit and water level indicator.

Request for a quote

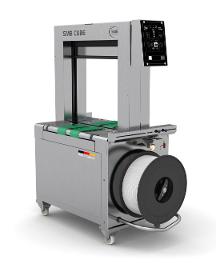

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Robust and extremely low maintenance Easy handling Minimum space requirement Stainless steel configuration ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks Conveyor speed steplessly adjustable Belt type or roller conveyor Stainless steel welding plate, low maintenance GreenTech energy concept, low power consumption High-Speed-Kit, optional Intuitive operator interface MFT 'Mono-Frame-Technology' Bundle press, optional SAO 'Safe and Open' - Safe without protection doors Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1002 series are direct support cylinders for vehicle construction. A robust cylinder connection is made possible by welding blocks. The support plates are ± 15 ° swivel. The cylinder connections have threaded holes for pipe connections according to BSPP ISO 1179-2. Hub and piston rod overhang are variably selectable. Control of the cylinders is possible on both sides via integrated hydraulically operated check valves in plate construction. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for detailed information:

Request for a quote

GSW SCHWABE AG

Germany

Effortless 180° rotation via foot pedal and automatic mechanical locking Optional sensory position readout Crank expansion via directionally stable joints, easily operable even under weight Highestquality arbor with maintenancefree bearing and minimal deflection Boxshaped stand with welded base plate for great stability LMHD Series PullOff Reel with manually adjustable brakes LMHDM Series Payoff Reel with threephase motors for start / stop operation LMHDR Series Payoff Reel with threephase motors and frequency inverter for continuous operation Pneumatic hold down arms Electropneumatic brake systems Larger mandrel segments Conical mandrels Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc.

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Crank expansion via directionally stable joints, easily operable even under weight Highestquality arbor with maintenancefree bearing and minimal deflection Boxshaped stand with welded base plate for great stability LMH Series PullOff Reel with manually adjustable brake LMHM Series Payoff Reel with threephase motor for start / stop operation LMHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic hold down arm Electropneumatic brake system Larger mandrel segments Conical mandrel Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

A new generation of bright welding wires With the development of WDI PLATINARC, we have succeeded in combining the good properties of copper-plated and non-copper-plated welding wires. The Platinarc welding consumables are characterised by therefore by: Low contact tip wear Best wire feeding properties Minimal silicate precipitation in the weld sea Low splash formation Low copper content in welding fumes Stable electric arc

Request for a quote

KELVION HOLDING GMBH

Germany

Our fully-welded plate heat exchangers make a convincing case due to their minimal size, outstanding thermal transfer coefficients and comparatively minimal investment costs. They are particularly robust and require only minimal cleaning and servicing. Their design advantages come into play especially in areas, in which, in addition to the output, load capacity is also a requirement.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Hanging handle in lengths from 200mm to 1200mm, made of U-profile with welded head plate. Particularly versatile due to design with special perforation on three sides. Fastened to horizontal concrete ceilings with dowels approved by building authorities. Two-sided cantilever mounting possible with standard wall cantilevers.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Hanging handle in lengths from 200mm to 1200mm, made of U-profile with welded head plate. Particularly versatile due to design with special perforation on three sides. Fastened to horizontal concrete ceilings with dowels approved by building authorities. Two-sided cantilever mounting possible with standard wall cantilevers.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Hanging handle in lengths from 200mm to 1200mm, made of U-profile with welded head plate. Particularly versatile due to design with special perforation on three sides. Fastened to horizontal concrete ceilings with dowels approved by building authorities. Two-sided cantilever mounting possible with standard wall cantilevers.

Request for a quote![Suspended support with welded head plate. [Kopie]](/filestore/vig280/opt/product/46/47/product_164f06bc.jpg)

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Hanging handle in lengths from 200mm to 2000mm, made of U-profile with welded head plate. Particularly versatile due to design with special perforation on three sides. Fastened to horizontal concrete ceilings with dowels approved by building authorities. Two-sided cantilever mounting possible with standard wall cantilevers.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Wall bracket, width 210 mm, heavy-duty version, with welded head plate, for fastening on U suspended supports and concrete walls. Corrosion protection: Hot-dip galvanised according to DIN EN ISO 1461 Dimensions: 210 x 90 mm Width: 210 mm Load capacity: 5.5 kN Make: OBO Bettermann Type: AW 55 21 FT

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Wall bracket, width 210 mm, light-duty version, with welded head plate, for fastening on U suspended supports and concrete walls. Corrosion protection: Hot-dip galvanised according to DIN EN ISO 1461 Dimension: 210 x 60 mm Width: 210 mm Load capacity: 1.5 kN Make: OBO Bettermann Type: AW 15 21 FT Item no. : 6420680 Make: OBO Bettermann Type: MWA 12 21S FS Item no. : 6424732

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Wall bracket, width 210 mm, medium-duty version, with welded head plate, for fastening on U suspended supports and concrete walls. Corrosion protection: Hot-dip galvanised according to DIN EN ISO 1461 Dimensions: 210 x 70 mm Width: 210 mm Load capacity: 3 kN Make: OBO Bettermann Type: AW 30 21 FT Item no. : 6419720

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Custom-designed clamping systems for pipes, tubes, hoses, cables and other components according to customer`s specifications or based on STAUFF developments, made of thermoplastics, metals and non-ferrous metals. Accessories such as weld plates, cover plates, bolts as well as rubber inserts are available on request.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

In many areas, stud welding is considered to be the most economic fastening method for components and is sometimes even the only technically feasible solution. Because the stud is joined with the substructure over the entire surface of the stud without any hollow areas, a high strength can be achieved. STAUFF is now using this proven principle for the installation of pipe, tube, hose and cable clamps in the Standard and Twin Series (according to DIN 3015, parts 1 and 3) with M6 mounting thread, where female threaded weld studs replace the regular weld plates; distance plates made from plastic provide the necessary spacing between the clamp bodies and the substructure. If required, the system can also be adopted for alternative fastening methods, e.g. for clamping belts, cable ties or corrugated cable protection hoses. In addition to the individual components – weld studs, distance plates, clamp bodies and metal hardware required – the company also provides the correspondingly...

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which comes with a base plate (150 x 150 mm), has been approved by the German Institute for Construction Technology ("DIBt"). It is installed on a steel structure and countered on the other side. The welded-on supporting tube (Ø 42 mm) easily withstands the pre-tensioning stress to which it is subjected when used in a lifeline system. Our standard package includes a set of installation materials. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Incl.stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

Thanks to its base plate (150 x 150 mm) and welded-on supporting tube (Ø 42 mm), this stainless steel anchorage point offers plenty of stability when used in a lifeline system installed in a concrete hollow core slab ceiling. Simply install the anchor on the substructure using the 4 slab expansion anchors supplied. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, C & CEN/TS 16415:2017 Base plate + welded-on supporting tube Designed for concrete hollow core slab ceilings ≥ C45/55 (B55) Web depth min. 25mm Installed using 4 expansion dowels Can be installed in cavities and solid material

Request for a quote

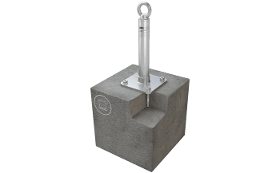

ABS SAFETY GMBH

Germany

This reinforced, stainless steel anchorage point - designed for concrete applications - does not create any tension in the substructure and is suitable for unprotected surfaces. It includes a base plate (150 x 150 mm) and a welded-on supporting tube (Ø 42 mm) for extra stability and is installed using the 4 anchor rods supplied. All you need is an installation depth of a mere 60 mm. EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Concrete ≥ C20/25 For installation depths ≥ 60mm Recommended accessories: Special Adhesive WIT-VM-250 Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

Thanks to its base plate (150 x 150 mm) and welded-on supporting tube (Ø 42 mm), this anchorage point offers a high level of stability when installed on a concrete structure - even with an installation depth of a mere 65 mm. This anchor - which has been awarded national technical approval - is easily installed using the 4 drive-in dowels supplied. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Concrete ≥ C20/25 For installation depths ≥ 65mm Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which can be used by one individual for abseiling purposes, comes with an extra-thick base plate (150 x 150 mm) and a welded-on supporting tube (Ø 42 mm). It is simply embedded in concrete using the 4 drive-in dowels supplied. EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Designed for C20/25 concrete ≥ 120 mm For installation depths ≥ 70 mm Secures up to 3 individuals Suitable for usage by 1 individual for recurrent abseiling work Incl. stainless steel installation set

Request for a quote

KLN ULTRASCHALL AG

Germany

In the last few years KLN has enlarged their hot plate welding machine program „TOOLMASTER“ and their vibration welding machine program “LVW” by the infrared welding program. The KLN machine program of „pure“ IR welding is based on the hot plate machine program „TOOLMASTER”. Machines for infrared heating should be equipped with servomotor drives in order to guarantee simple, quick and exact positioning. For welding by means of infrared technology short-wave (0,78-2 μm) as well as medium-wave (2-4 μm) infrared radiation of the spectrum can be used. This depends particularly on the radiation absorption capacity of the respective polymer material. The more precisely the radiator is adapted to the absorption capacity of the polymer material, the higher is the degree of efficiency, that means the conversion into warmth. Short waves are absorbed in deeper layers of the material, whereas medium waves heat it up more at the surface.

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Trailer landing gear, short design, static load 50 t, dyn. load 24 t, with compensating or rocking foot, full length welded back plate, matching to 'Mega-Trailer'- vehicles

Request for a quote

SCHAKE GMBH

Germany

for universal protection of building sites, continuous support tube, with welded plate for mounting in the base plate, film red / white attached on both sides, reflec- ting, film area protected by outer edge, socket 60 mm x 60 mm or 40 x 40 mm

Request for a quote

OGE GROUP

Germany

SS Plate Bundles Welded on De-hydrogenation Reactor Vessel

Request for a quoteResults for

Welded plates - Import exportNumber of results

31 ProductsCountries

Company type

Category

- Industrial cabling (7)

- Metal straightening machines (2)

- Agricultural machines and accessories (1)

- Automation - systems and equipment (1)

- Gas and oil - exploitation (1)

- Grids, gratings and wire mesh (1)

- Heat exchangers (1)

- Plants (1)

- Signs and signalling panels and boards (1)

- Steels and metals - welding and brazing (1)

- Ultrasound systems - Processing plastics (1)

- Vehicles - accessories and equipment (1)

- Wires and cables, steel (1)