- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibrating table

Results for

Vibrating table - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

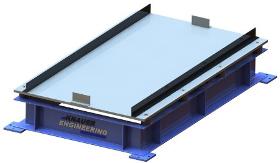

AViTEQ Vibrating table can be used both for compression and also for loosening bulk material. Typical applications are compacting of e.g. concrete mixes or the unstick/knock out of molds. There are two different approaches: The load to be vibrated, is set loosly on the table or firmly clamped to the vibrating device. Advantages & benefits variable, can be used for different tasks easy to regulate with magnetic vibrator Construction Compact design, with attached magnetic vibrator/s or unbalanced motors below the tabletop. Selection The sizing depends on: bulk material, such as bulk density, particle shape and internal friction the properties of the container, such as height, stiffness and sidewall Key figures length: up to 4,000 mm width: up to 2,000 mm payloads: up to 3,000 kg drive: magnetic vibrator, unbalanced motor, exciter

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

To view and download the brochure please click on the left image. Video Vibrating table to compaction of materials Video Vibrating beams to produce concrete elements

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

To view and download the brochure please click on the left image.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

To view and download the brochure please click on the left image. Vibrating table for the produktion of prefabricated mineral cast This plant has been developed for the company EPUCRET for the production of machine frames out of mineral casting. EPUCRET has been active for over 20 years at the cutting edge of polymer-bonded mineral casting technology and offers its customers from the mechanical, plant and appliance engineering industries a competent all-round service for system solutions using mineral castings. (for further information see www.epucret.de). During the development of the machine it had to be considered that the production program reaches from small over medium sized to large products und that these had to be produced efficiently on this plant. The plant consists of 2 vibrating table which are suspended by air springs and which can be run simultaneously or independently. The working level is being kept constant by a level control. During the production of small and...

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

We offer custom made vibrating Systems, tailored to our customers Needs.n

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

For KNAUER ENGINEERING-Vibrating Tables there are many fields of application in several industry branches. Examples: • Compaction of concrete elements • fast and economic filling and emptying of containers with bulk goods; • deairation of viscous liquids; • sorting and distributing of bundled tubes or similar elements. Besides some standard vibrating tables most vibrating tables are being designed and manufactured according to customer requirements. From small, simple vibrating tables up to very large tables with, e.g. hydraulic mould clamping, electronic amplitude adjustment and automatization.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Vibrating tables suitable for testing and quality inspection of sensitive components The vibratingsystems are employed for simulation of stress created by mechanic vibrations on mechanical and electrical components and subassemblies with the following features: Direction of oscillation: linear - horizontal (sinusoidal oscillation), adjustable by means of a selector. Either oscillation in x-axis or alternatively in y-axis

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The compact design allows to generate high centrifugal forces and requires minimum space. This is often necessary when used in machines. Fields of application are e.g.: Ram vibration of block making machines, vibrating table, battery formworks. Special Features are: • Centrifugal force from 0,5 kN to 16,5 kN • Speed from 1500 RPM to 3000 RPM

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The very robust design allows extremely high mechanical and electrical (Heat) loads, which occur in machines with e.g. very short cycle times. Fields of application are e.g.: Table vibration of block making and pipe machines, etc, knock out grates, Vibrating beams. Special Features are: • Centrifugal force from 14 kN to 40 kN • Speed from 1000 RPM to 3000 RPM

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

GEBR. RETTBERG GMBH

Germany

Attention:Delivery is made by forwarding . Freight costs as incurred. This flat rack out of stainless steel has adjustable feet and a damping. The wage and device plate (54,0 cm x 54,0 cm) will be inserted in the rack and put on your laboratory table. The effect is that your laboratory table will be upgradet to a wage table. Article number for wage and device plate : L58745001 Geben Sie Text oder eine Website-Adresse ein oder lassen Sie ein Dokument übersetzen. Abbrechen Verwendungsbeispiel für "": Automatisch von Google übersetzt

Request for a quote

GEBR. RETTBERG GMBH

Germany

Heavy Stone Plate. Polished and smooth. Shock-absorbing Tape under the Plate minimises vibration. This tape also prevents the undermining of chemicals. Granite Stone is highly durable. The polished and sealed surface also allows for use in clean rooms. The leveling is done by the feet of the established scales or units. Delivery is made by forwarding agency. Freight costs as incurred.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

Our gantryLine models can process large, wide and heavy workpieces up to lengths of 5000 mm and widths up to 2000 mm with high precision. Special designs are also available to process wider and longer workpieces. This machine line with its variety of available features is suitable for surface grinding applications all the way through complex CNC manufacturing cells. Next to the horizontal grinding spindle a vertical tiltspindle can be mounted for grinding for example machines beds with under grip. The sturdy gantry-style machine design features a modern vibration-free mechanical table drive, linear guideways in all axes, an over-sized spindle drive as well as ball screws and linear scales in vertical and cross axes. These features guarantee that today’s expectations in the precision machining of large surfaces are met for rough machining and high precision machining as well. The gantryLine achieves highest workpiece precision and surface quality.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec Big Bag filling stations are suitable as standard for filling big bags with a capacity of up to 2 tons. Various options are available to meet the required task. Also a calibratable weighing of the filled Big-Bas. The Big-Bag filling station offers a variety of options: - height-adjustable suspension frame - Tightening of the big bag by means of linear drive - Double big bag filling - vibration table for compacting the products, etc., ... to name just a few.

Request for a quoteResults for

Vibrating table - Import exportNumber of results

15 ProductsCountries

Company type