- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibrating feeders

Results for

Vibrating feeders - Import export

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— No stirring agitator or other rotating parts for ingredient flow without degradation — Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range Power range 10 - 450 dm³/h 20 - 1000 dm³/h 300 - 3000 dm³/h 650 - 6500 dm³/h

Request for a quote

HOCHRAINER GMBH

Germany

The availability and output of a production system is only as high as the process reliability of its feeding systems allows. Thanks to more than 35 years of experience as a system supplier for assembly technology and custom machines, we can implement a large variety of applications tailored to customers' requirements;

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Unbalance motors can be used as drives for almost each case of application in the vibration feeder technology and over all industries. Unbalanced motors are the prefered drive system, in particular if it depends on high throughput of bulk material. Advantages and benefits available as standard for explosion proofed ATEX zones 21+22 available as standard for CSA-apllication "Class 1 + 2" available as standard with thermistor operationally safe in continuous employment high level of performance with compact dimensions efficiency latest state-of-the-art of technology and production conformity with all EC Guidelines which affect the drives available for 60 Hz power systems and other mains voltages Construction and operation mode The AViTEQ unbalance motor is a three-phase ac induction motor, on which weights are eccentrically attached at the ends of the running shaft; so-called eccentric weights (flyweights). Centrifugal forces are generated with rotating waves. The value of these

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Magnetic vibrators can be used very versatile. The advantages of magnetic vibrators match all designs of vibrating machines. For almost each case of application in the vibration feeder technology and over all industries magnetic vibrators are the favorite system, in particular if it depends on high dosing accuracy. Magnetic vibrators are made in Germany on a highest standard. Advantages and benefits easy and continuously adjustable during running conditions PAL System (protection for wrong amplitudes) available for 25/33/50/100 (30/40/60/120)Hz variants immediate start/stop after switching linear amplitude Reliable permanent use High level of performance with compact dimensions Wear-free, without rotating parts Efficiency (long operating cycles and service life) Newest state-of-the-art of production engineering Conformity with all EC Guidelines, which affect the drives available for explosion-endangered spaces (Ex) available for 60 Hz power systems and other mains voltages Temp

Request for a quote

WHITE STEEL GMBH

Germany

Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

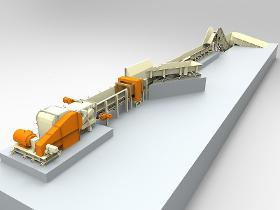

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient drum chippers, the production of high-quality chips is guaranteed. Key features Simple feeding of wood directly from the truck Robust underground bins or vibrating feeders Vibrating conveyor lines Drum chipper Metal sensor and roller conveyor cleaning system Advantages Use of almost any type of wood material Continuous and uniform material feed Safe removal and discharging of rocks, sand, and other contaminants High lling level and high utilization of chipper capacity

Request for a quote

HAVER NIAGARA GMBH

Germany

Conveying technology has a top priority at HAVER NIAGARA. Our vibrating feeders can be used in all the industrial fields where HAVER & BOECKER is active. Not only vibrating feeders can be used, but also bunker discharge chutes. Uniform vibration assures an expeditious conveying speed while being gentle on the product. Depending on the requirements of our customers, we offer feeders with magnetic/eccentric drives or exciters. The same is true for the design shapes. Depending on the requirements, we have a variety of possibilities to design the feeder. The open, partially encapsulated, and completely encapsulated designs all belong to our product range, as do the multiple channel tube vibrating feeders. Thus we are optimally set up to successfully support our customers in everything having to do with their process chains. You’ll find detailed information in our product brochures and specification sheets.

Request for a quoteResults for

Vibrating feeders - Import exportNumber of results

8 ProductsCountries

Company type