- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vanes

Results for

Vanes - Import export

PFEIFFER VACUUM GMBH

Germany

Single-stage rotary vane pumps from Pfeiffer Vacuum have long been some of the most widely used products for processes in the low and medium vacuum range. Their long life and pumping speed, irrespective of the gas used, are the outstanding properties of this pump. Typical applications are found in widely ranging sectors: — Analytics (mass spectrometry, electron microscopy) — Coating technology (surface protection, decorative films, display units, monitor screens) — Vacuum metallurgy (vacuum soldering, vacuum sintering, vacuum alloys, furnace construction) — Leak detection technology (vacuum systems, automotive tanks, airbag cartridges, packaging) — Lighting industry (light bulb manufacture) — Drying industry (vacuum drying, transformer drying)

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

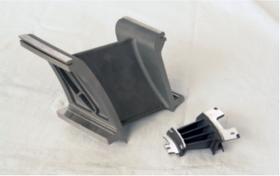

The guide vanes control the inflow of water in turbines. These vanes run in sliding bearings. To give the bearings longer term protection from water infiltration, the inner sealing MANOY® system seal WP, type 428, was developed for standard specifications. Type 487 with integral scraper was designed for high specifications due to abrasive constituents in the water and/or long inspection intervals. The housing for this seal must be open. The profile dimensions of both versions can be customized to adapt to existing groove designs.

Request for a quote

PFEIFFER VACUUM GMBH

Germany

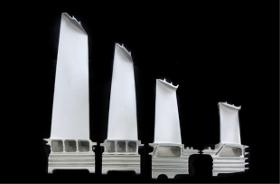

Dual-stage, high-performance rotary vane pump with a pumping speed up to 22 m3/h With 3-phase motor With temperature sensor (Bimetal) for optimum motor protection Integrated gas ballast and HV safety valve For all low and medium vacuum applications Special feature, Various motor voltages for worldwide employment

Request for a quote

PFEIFFER VACUUM GMBH

Germany

Magnetically coupledIn contrast to the standard pump, these products have a frictionless magnetic coupling. Oil leakage from a wear-prone conventional shaft seal is ruled out in these models Applications * - Installation in analyzers * - Installation in flywheels * - Gas technology Customer value * - Space-saving and ideal for systems integration * - High pumping speeds with small dimensions * - Low ultimate pressure * - Low-maintenance, no oil leaks from the shaft feedthrough * - Low operating costs, not necessary to replace shaft seals Duo 1.6 M * - Extremely low noise, ideal for laboratory applications * - Easy integration thanks to the UL and IEC 61010 certification of the entire pump * - With maintenance-free magnetic coupling

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NITTO KOHKI EUROPE GMBH

Germany

The flow of cooling water can be checked at a glance.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

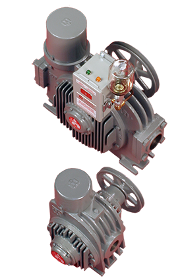

Proven in over 30 years of field operation, Waukee brand compressors are designed to be easy to maintain and service. This means that downtime is kept to a minimum. Features include simple design with few moving parts, rotary vane constructions, and built-in automatic closed-circuit unloader in which gas not needed is recirculated within the compressor. (Depending on pressure and flow rates, a bypass regulator may be used instead.) The 6-vane rotor is supported at both ends by factory sealed and lubricated ball bearings. Operation is relatively quiet. There are no gears, springs, or metal contacts. The low-friction vanes slide in and out of the rotor slots centrifugally. Capacity: The Waukee Rotary Vane Compressors can be provided from 200 cfh (5.6 cm/h) to 8,000 cfh (226 cm/h) at pressures up to 3 psig (20.68 kPa) on standard models.

Request for a quoteResults for

Vanes - Import exportNumber of results

10 ProductsCountries

Company type