- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum filter

Results for

Vacuum filter - Import export

FAUDI GMBH

Germany

Advantages High flow rate Various endless-filter belts or non-woven fabric can be used Cleaning system for endless filter belts Highly economic Area of application Vacuum filters are used for the cleaning of coolants, e.g. for central filter systems with high flow rates and machining processes like turning, drilling and grinding. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil and emulsion Filter material filter belt

Request for a quoteFAUDI GMBH

Germany

Advantages High flow rate Various endless-filter belts or non-woven fabric can be used Cleaning system for endless filter belts Highly economic Area of application Vacuum filters are used for the cleaning of coolants, e.g. for central filter systems with high flow rates and machining processes like turning, drilling and grinding. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid with Filtration degree 30-40 µm Medium oil and emulsion Filter material non-woven fabric

Request for a quote

F.E.S. GMBH

Germany

Vacuumfilters are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Compact size Excellent filtration results Low installation effort Low maintenance requirements Affordable price Optional configuration without consumable filter fleece, with continuous filter belt, and washing device Significantly lower consumption of filter fleece compared to gravity filter systems during challenging filtration tasks and fleece operation Operating Principle: The contaminated cutting fluid flows through a piping system (1) and an inlet distributor (11) into the dirt chamber (2) of the underpressure filter tank.

Request for a quote

R&S PAPIERVERARBEITUNGS-GMBH

Germany

You will find in our assortment: Exhaust air filters of different qualities e.g. M dust class, also in wet-proof, L dust class Micro-hygiene filter, one of our novelties in the assortment Micro-hygiene-filter + exhaust air filter in a set Motor protection filters in various diameters, thicknesses and designs for vacuum cleaners of well-known manufacturers

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Suction immersion pumps series TAS/STS make it possible to connect to vacuum filters through their simple connection on the suction side (for instance, with a slot screen). Suction immersion pumps without seals are positioned in the area of unfiltered coolant in the tank. With their robust design, they allow operating pressures of - 0.3 bar to - 0.5 bar on the suction side. Volumetric delivery: up to 1200 l/min Delivery head: up to 60 m The STS serie offers a flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Please contact us for delivery quantity

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Filter VFI Connect. Schlauch-Ø 4 .. 6 inline vacuum filter for direct installation on hose lines

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Filter VFT Connect. G1/8 ... G1/2 Vacuum filter made of plastic with clear glass lid for ejctors and small vacuum pumps

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Filter SFS Connect. Hose-Ø 50 ... 60 Vacuum filter with plastic housing for vacuum blower with high flow rate

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Filter VF Connect. G3/8 ... G21/2 Vacuum filter with sheet metal housing for vacuum pumps and smaller blowers

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Water Separator WA Connect. G1/2 ... G11/2 application with wet or moist surfaces

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Ventilation Filter BF Connect. G1/2 ... G11/2 ventilation filter for installation on vacuum valves on the ventilation side

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Ventilation Filter BFS Connect. G1/8 ... G1 ventilation filter for installation on vacuum valves on the ventilation side

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

to give the AERO-LIFT customer the best comfort and ergonomy, there are some additional options for our vacuum lifting devices Cran control holder to fix the crane control at the manipulating handle grip. The crane control holder is universal and is compatible to all crane controls. Fixing cran control Fixing cran control cran control holder cran control holder mounted cran control holder at the device handle cran control holder mounted Signal lamps big round signal lamps for the Rundleuchten für die intelligent electronic warning system. green light signs if vacuum is higher than 60%, red light signs if vacuum is under 60% in the vacuum tank. Option: big signal lamps Warning system with signal lamps Cable reel with 5m or 10m Cable reel with mit heald spring motion - 5 m cable or 10 m cable, 5x1,5 mm², 400V Waterseparator To keep dry the vacuum pump and the following system you need a water serarator in place of a vacuum filter. Its easy to emptying the water separator...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

COMBER Pressofiltro® / Turbodry® Series PF/TD 5 - PF/TD 100 This Pilot Plant can either be used as Agitated Nutsche Filter/Filter Dryer or a Vacuum Dryer. Designed for processes in pilot plants, it is fully equipped for tests and trials and can as well be used for small scale production. Special properties for the customer’s benefit: Calculation, manufacture and design are in accord with Pressure Equipment Directive 97/23/EG or/and ASME U-stamp as well as with cGMP and FDA guidelines Approved for using in ATEX danger zone, group II 2G 2D (zones 1/ 21) Suitable as vacuum dryer, filter dryer or agitated nutsche filter Shaft seal through gland nut Device built on skid Control system protected against explosion (EEx-d) Options Multilayer PLC-system

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

Our mobile ultra fine filter system M 110 is a processing machine for oils with coarse impurities such as swarf and suspended solids. Equipped with a washable pre-filter, coarse impurities are kept away from the main filter which significantly increases its life service once again. It is constructed very robust and is easy to operate. The vacuum display on the pre-filter enables an unattended continuous operation after switching on. An automatic pressure control and shutdown are also standard equipment of the M 110. In the processing of cutting oils for example, it stands for extremely short amortization times. 230 V-alternative 400 V motor, robust and reliable, stable gear pump Manometer for flow- and element control and for vacuum display in the pre-filter Pressure switch for selection setting in unattended operation 24/7 – unattended operation Pumping without filtration (transfer) Flow regulation for high viscosity oils Element lifter for simple and fast element exchange

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

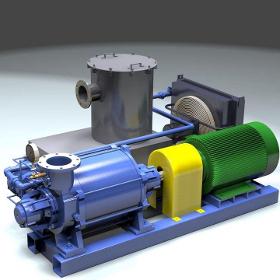

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quote

PROAIR GMBH

Germany

Clean the air directly when vacuuming! With the DELPHIN you can solve all typical vacuum cleaner problems. Every vacuum cleaner has to live with the compromise between suction power and retention capacity and the filters clog with sucked-in dust, which gradually reduces the suction power. With the DELPHIN, the polluted air is led into the water right at the beginning, whereby dust and pollutants are bound directly in the water. The click lamella creates an intense water vortex and is also a further cleaning stage. This system works so efficiently that it even binds fine dust and coronaviruses safely in the water. The water is simply thrown away after use. Due to the special construction of the DELPHIN DP S8, absolutely without filters, foams or sound insulation mats, the self-drying function can ensure a long service life. You can place the DELPHIN in the room as an air purification device. Or you can use the DELPHIN to clean floors and furniture.

Request for a quoteResults for

Vacuum filter - Import exportNumber of results

23 ProductsCountries

Company type