- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ultrasonic cleaning

Results for

Ultrasonic cleaning - Import export

PERO AG

Germany

Sound waves generated by an oscillator agitate the wet medium. This leads to cavitation bubbles that implode at a high frequency and result in hydraulic impacts. These impacts combined with microflows flush particles and pigments off the parts. The costs of ultrasonic cleaning are primarily determined by the processing time. Low ultrasonic frequencies remove coarse dirt, while high ultrasonic frequencies are used to eliminate fine dirt from parts.

Request for a quote

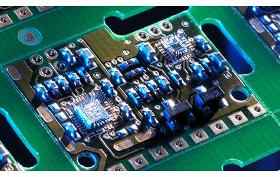

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Even if the production process uses NoClean fluxing agents, special requirements sometimes call for a special cleaning process: with our state-of-the-art ultrasonic cleaning system, we reduce ionic residual contamination to a minimum. As a result, the cleaned assemblies can be quickly and safely further processed. Our focuses: - Assembly cleaning - Checking for assembly cleanliness You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

ROLF KÖRNER GMBH

Germany

We produce filter discs and cuttings in any measurement and shape from wire cloths and metal fiber felts. All products can be ultrasonically cleaned, if requested!

Request for a quote

KLN ULTRASCHALL AG

Germany

For the various contaminations KLN Ultraschall AG offers cleaning agents particularly for ultrasonic and spray-cleaning machines. If you have a problem with cleaning, please send us your parts. In our cleaning lab we will carry out trials to test which cleaning agent is most suitable for you. Below please see a list of some special cleaning agents. However, we have a much larger product range. • Ultrax 1.9 L • Ultrax 6.4 L • Ultrax 7.1 L • Ultrax 9.2 L • Ultrax 11.5 L • Ultrax 13.12 L • Ultrax 14.4 L Particularly for form cleaning we recommend for Aluminium forms: Ultrax 13.12L and Ultrax 7.1L Steel and cast molds: Ultrax 14.4L and Ultrax 7.1L

Request for a quote

KLN ULTRASCHALL AG

Germany

Ultrasonic cleaning tanks of series SW 12, SW 25 and SW 40 are compact tabletop cleaning devices for industrial purposes. The serial version includes a cover with handle. The cleaning tanks can be equipped alternatively with frequencies of 30 or 40 kHz or in combination 30/40kHz. On the front the ultrasonic operation can be set nonstop or for a limited period. The ultrasonic generators are integrated in the stainless steel housings. The devices are equipped with a heating with thermostatic regulation installed at the outside of the tank. It is set on the front. The tanks are made of stainless steel, here the SW40 – SW90 are built in welded design. On the bottom they have a residual clearance. Heated and cold cleaning tanks complete the program. Only aqueous cleaning agents are permitted in the cleaning tanks.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our heatrecovery systems heat fresh air with the thermal energy of exhaust air and can be placed directly on top of a stenter frame. This system can also be retrofitted for older dryers. The benefits are high energy savings which allow payback periods of less than two years, depending on the layout and process, highly efficient platetype heat exchangers with nonstick coating, optimum ease of maintenance by removable drawersized heat exchanger modules, external cleaning of the heatexchangers in a hot water bath with ultrasonic cleaning equipment, high power density, higher than with usual tubetype heatexchangers.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Characteristics: - Highest dosing accuracy - Precise closure parts assembly - Flexible servo drives - Turning station with torque control - Greatest possible efficiency - fAccurate transfer at discharge Options: - f100% leak test - Check weighing - Automatic sorting and feeding systems - Die-cut module for lid - Gassing - Ultrasonic sealing - Laser coding - Container cleaning

Results for

Ultrasonic cleaning - Import exportNumber of results

8 ProductsCountries

Company type