- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turning tools

Results for

Turning tools - Import export

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

In face turning the tool moves vertically to the axis of the work-piece. When rough machining, a tool movement from the outside of the work-piece to the inside is preferred; in finish machining, the preferred movement is from the inside to the outside. The largest possible corner radius should be chosen in order to ensure optimal tool stability and cost-effectiveness.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Contrary to external turning, tool selection and tool use are of greater significance in internal turning as these are limited by the length and hole diameter of the work-piece. During internal turning it is very important to select a boring bar which is optimal for the hole diameter in order to minimise vibrations. Zinner tools are available in steel, heavy metal or hard metal shanks.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

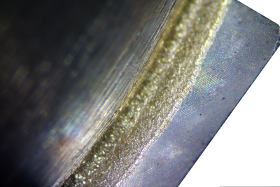

ZINNER PKD or highly positively polished cutting inserts are used for machining aluminium and copper. Glass-fibre reinforced materials are machined with PKD or coated PKD tools. Diamond tools are ideally suited for the high gloss turning of non-ferrous metals.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

CBN (cubic boron nitride) is the next hardest material after diamonds. When properly used, tools made from CBN exhibit considerably less wear than other materials. Cutting inserts or even VHM tools can be equipped with CBN. Technical application: Hardened tool steels with hardnesses greater than 55 HRC or high speed steels (HSS) can be machined without problems using CBN. Case hardened steels and chilled cast iron can also be machined with CBN. Non-ferrous metals are totally unsuitable for CBN; diamond tools are needed for these.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Thread turning is a special turning process.In thread turning a distinction is made between three different forms of presentation; the use of these depends on the thread pitch, the machine tool, the work-piece material and the cutting edge geometry. In the case of large threads, the tool must traverse the same track several times, penetrating deeper each time. The full depth of cut is therefore divided into several smaller cuts, thus preventing an overload on the sensitive tip of the thread profile of the cutting edge. In order to ensure profile accuracy, the helix angle of the thread must coincide as far as possible with the angle of inclination of the threaded plate. Thread turning method

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Complex machining processes can now be completed with fewer tools as a result of the use of profile turning tools (also called turning-milling tools). The use of profile turning tools enables the number of tool positions in the tool changer to be reduced.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

When turning outside diameters, it is necessary to consider which clamping system should be used and which components will be made most often. This is because if larger components are to be turned (and therefore with correspondingly greater depths of cut) a different system must be used than when turning smaller components with a finishing pass. Determining the cutting direction and tool holder A turning tool which works from right to left is called a right-hand turning tool because it machines the right-hand side of the work-piece (when looking at the tool point, the main cutting edge of the turning tool is on the right). View of internal and external turning Clamping systems The C Clamping System, P Clamping System, the M and S Clamping Systems. ISO Key image

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

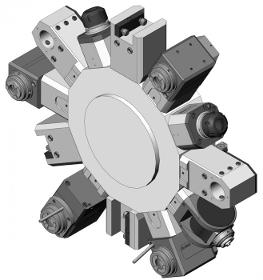

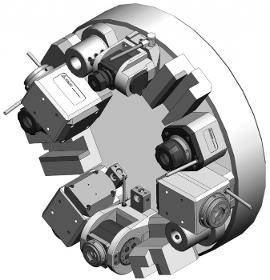

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quote

WIGTEC FISCHEREDER KG

Germany

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

BERNSTEIN AG

Germany

Thanks to their standard dimensions as well as the wide range of contacts and actuators, the IN65 switches can be used on safety facilities and for position monitoring in virtually any industrial application. The modularity allows for great flexibility, enabling individual customer solutions to be realised. Due to the metal actuator locking and mounting clip the product is particularly robust. The IN65 ideally combines the economic advantages of a plastic bodied switch, with the sturdiness of a metal bodied one. Standard switches conforming to DIN EN 50047 Modular design High reliability at low currents (1 mA) Tool-free turning and changing of actuator Metal actuator locking Metal mounting clip Protection class IP66 and IP67 Hinged snap-on cover

Request for a quote

SYSKOMP GMBH - EMICO

Germany

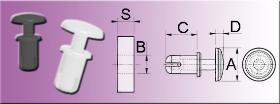

These rivets can be brought into the right position with one turn. No tools required! Mountable by the press of a finger. Material: PA 6 , UL 94 V-2 Colours: last digits 600 = white last digits 699 = black Further types on written request.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VD2 refaces the valve seat in a lathe-type facing action. The tool head includes two inclined slideways for refacing 30° and 45° valve seats. A single point turning tool is clamped to tool slide guided in the respective slideway. When the VD2 is rotated around the pilot by hand, the turning tool travels in a circle around the valve seat with continuous outward transverse feed motion under the correct seat angle. A steady rest which is mounted on the cylinder head stabilizes the VD2 below the crank handle. The steady rest eliminates runout when rotating the VD2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VDS2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VDS2 refaces the valve seat in a lathe-type facing action. A gear head includes a feed mechanism for continous outward transverse motion of the single point turning tool when the VDS2 is rotated around a pilot inserted in the valve guide. The direction of the feed motion is defined by an exchangeable adapter head screwed to the gear head. A steady rest which is mounted on the cylinder head stabilizes the VDS2 below the crank handle. The steady rest eliminates runout when rotating the VDS2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VDS1A is designed to reface valve seats of the engines of motorcycles, cars and light commericial vehicles. Features The VDS1A refaces the valve seat in a lathe-type facing action. A gear head includes a feed mechanism for continous outward transverse motion of the single point turning tool when the VDS1a is rotated around a pilot inserted in the valve guide. The direction of the feed motion is defined by an exchangeable adapter head screwed to the gear head. A steady rest which is mounted on the cylinder head stabilizes the VDS1A below the crank handle. The steady rest eliminates runout when rotating the VDS1A around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • Strapping applied in transport direction without bundle turning • Easy accessibility and tool-free dismantling of strap path components • Potential-free contacts to upstream and downstream machines • Infinitely adjustable conveyor speed from 0.1 to 1.0 m/s • Optimization of the strapping processes by machine adaptation to defined package dimensions • Energy-efficient, electro-mechanical hold-down device (also available as pneumatic version) • CE marking inclusive conformity declaration • Extremely low energy consumption [Base] • Easy operation over digital display in the control panel [Pro] • Intuitive user guidance via colored touch panel; division into different user groups

Request for a quote

MINEON HANDEL GMBH

Germany

Bright Chrome plate Zinc Alloy Quarter-Turn Lock,different Insert Type available,LH/RH available,Head Diameter Ø28,Door Cutout: Ø22.5*20.1mm,Easy Installation,ROHS compliance

Request for a quote

MINEON HANDEL GMBH

Germany

Zinc Alloy and Stainless Steel versions available,Housing Lengths 18mm,28mm,36mm,62mm available,different Insert Type available,Head Diameter Ø28,Door Cutout: Ø22.5*20.1mm,Easy Installation,ROHS compliance

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAPP NILES GMBH & CO. KG

Germany

Beside the non-dressable CBN grinding tools, dressable grinding tools of leading manufacturers can be used on our machines, too. Vitrified bond aluminium oxide tools are dominant. Sintered aluminium oxide is preferred as the grinding tool for grinding of steel due to its resilience and grinding capability. Gray cast-iron can also be processed with normal aluminium oxide. The profiling of the grinding tools takes place via a machine-integrated CNC dressing unit. A diamond-plated, rotating dressing tool profiles the wheel in accordance with the respective gear parameters. The grinding tool is conditioned specifically for rough or finish grinding by selecting respective technological dressing parameters. Form consistency and cutting capacity of the grinding wheel is assured by repeated dressings, dependent on pre-defined stock removal rates. The automatic balancing produces smoother turning for larger grinding tools, and consequently, high gear quality. dressable CBN tools Single-layere

Request for a quote

RUHFUS SYSTEMHYDRAULIK GMBH I.L.

Germany

Contract Manufacture We also make our machining facilities available to businesses that just want to outsource specific production processes. Here we focus on being used in the field of deep drilling, peeling and rolling, and in honing. We are also happy to make our capacity available in the field of machining, welding and blasting and painting. In particular by the extension of our machining capacity by several CNC-controlled 4-axle turning centres with driven tools, a modern welding plant for tubes up to 16,000 (18,000) mm length and an efficient paint shop, further capacities have been created here.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holder for machines: NL 1500 NL 2000 NL 2500 NL 3000 NT 4250 NZ 1500 NZ 2000 NT 1000 NT 2000 NTX 1000 NTX 2000 Available in the following versions: Square locking drive radial Turning Tool holder axial Turning Tool holder axial double Boring bar holder Boring bar holder double Infeed Toolholder

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holder for machines: Doosan PUMA MX 1600 ST Doosan PUMA MX 2100 ST Doosan PUMA TT 1500 MS Doosan PUMA TT 1500 SY Doosan PUMA TT 1800 MS Doosan PUMA TT 1800 SY Available in the following versions: Square locking drive radial Turning Tool holder axial Turning Tool holder axial double Boring bar holder

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holder for machines: Life tool C-Revolver VL 3 VL 5 VSC 200 VSC 250 Available in the following versions: Square locking drive radial left Turning Tool holder axial left Boring bar holder

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holders for machines: Nakamura SC-250 Nakamura TMC 18 Nakamura TW 10 Nakamura TW 41 Nakamura WT 20 Nakamura WT 150 Nakamura WT 250 Nakamura-Tome Super NTJ Nakamura-Tome Super Nakamura NTX Nakamura SC-300 Nakamura SC-300 L Nakamura SC-300 LM Nakamura SC-300 M Nakamura TW 20 Nakamura WT 300 Nakamura-Tome Super NTX Available in the following versions: Square locking drive radial Turning Tool holder axial Turning Tool holder axial double Boring bar holder

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holder for machines: Biglia B42 Biglia B111 Daewoo PUMA 200 Duplomatic VDI 30 Hyundai Kia SKT 100 Weiler DZ 42 (12-fach Revolver \ 12 tool mounts turret) Weiler DZ 65 YCM GT 200 MA Biglia B56 Biglia B200 Hyundai Hit 250 M Hyundai Hit 250 S Topper TB 25 YMBL Available in the following versions: Square locking drive radial right Square locking drive radial left Turning Tool holder axial right Turning Tool holder axial left Boring bar holder

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holder for machines: HL 1 HL 2 HL 3 HL 4 SL 20 SL 30 TCE 550 TCE 550 T TCE 860 TCE 860 T TL 15 TL 25 SL 20 „Hybrid-Turret“ SL 30 „Hybrid-Turret“ SL 40 „VDI-Turret“ TL 15 „Hybrid-Turret“ TL 25 „Hybrid-Turret“ Available in the following versions: Square locking drive radial left Turning Tool holder axial left Boring bar holder

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holders for machines: Multiplex 610 (12 tool mounts turret), 615, 620, 6200 (12 tool mounts turret), 6200 Y, Multiplex3 8200 Y, 610 (16 tool mounts turret), 6100, 6100 Y, 6200 (16 tool mounts turret), 630, 6300, Super Quick Turn 10 (16 tool mounts turret) Quick Turn Nexus 200 M / MS / MSY (12 tool mounts turret), 250 M / MS / MSY (12 tool mounts turret) Super Quick Turn 15 M, 18 M, 200 M (12 tool mounts turret), 250 MY (12 tool mounts turret) Quick Turn Nexus 100 M/MS/MSY Quick Turn Nexus 200 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 250 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 300 / M / MY, 350 / M / MY, 400, 400 / M Super Quick Turn 28, 30, 300 M / MY, 350 M, 10 M/MS, 100 M, 10 M/MS, 100 M, 200 M (16 tool mounts turret), 250 M (16 tool mounts turret) Available in the following versions: Square locking drive radial Turning Tool holder axial Boring bar holder with IC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Live Tools for machines: Multiplex 610 (12 tool mounts turret), 615, 620, 6200 (12 tool mounts turret), 6200 Y, Multiplex3 8200 Y, 610 (16 tool mounts turret), 6100, 6100 Y, 6200 (16 tool mounts turret), 630, 6300, Super Quick Turn 10 (16 tool mounts turret) Quick Turn Nexus 200 M / MS / MSY (12 tool mounts turret), 250 M / MS / MSY (12 tool mounts turret) Super Quick Turn 15 M, 18 M, 200 M (12 tool mounts turret), 250 MY (12 tool mounts turret) Quick Turn Nexus 100 M/MS/MSY Quick Turn Nexus 200 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 250 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 300 / M / MY, 350 / M / MY, 400, 400 / M Super Quick Turn 28, 30, 300 M / MY, 350 M, 10 M/MS, 100 M, 10 M/MS, 100 M, 200 M (16 tool mounts turret), 250 M (16 tool mounts turret) Available in the following versions: BENZ Solidfix® axial BENZ Solidfix® radial BENZ Solidfix® offset Collet Chuck axial Collet Chuck radial Collet Chuck radial offset Collet Chuck swiveling

Request for a quoteResults for

Turning tools - Import exportNumber of results

28 ProductsCountries

Company type