- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transducer sensors

Results for

Transducer sensors - Import export

IGUS® GMBH

Germany

Initiator cables, also referred to as sensor/actuator cables, connect control units and different sensors, or, in the case of reversal of the measurement principle, actuators. Frequently used abbreviations include ini or ini cable (plural: inis). Sensor or measurement transducers transform physical quantities such as rotation, speed, distance or length into analogue electric impulses. In the case of an actuator, the measured electric current (symbol: I, unit: ampere; A) or voltage (symbol: U, unit: volt; V) is transformed into temperature, pressure or torque. The connection cable consists of at least three cores with a small cross-section of between 0.14mm² and 0.34mm². In the simplest case, two cores are required for supplying the voltage, while the last core transmits an I/O signal. For sensitive applications, there are shielded versions in addition to the traditional ini cables to avoid EMC disruptions (electromagnetic compatibility).

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures. Typical application fields are displacement and extension measurements on: —Machines —Servo systems —Motor vehicles —Test benches —Production plants The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Linear displacements and mechanical values which can be converted to displacements (e.g. compressive and tensile force, strain, torque and vibration) may be measured by these DC/DC displacement sensors. The probe tip of these sensors is pushed onto the measuring object by a spring. This makes it possible to use these sensors were a mechanical modification of the measurement object (mounting hole) is not allowed or difficult. Output voltage as function of the displacement with the impedance as parameter. Sensors of series 87350 generally consist of an oscillator, a demodulator and a transformer with moveable core. They are energized by DC voltage. The oscillator uses this DC voltage to generate the carrier frequency, which is needed for the operation of the sensor. Dependent on the position of the core, which is made of ferromagnetic material, voltages are induced by the two secondary coils of the transformer.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Displacement and all mechanical values which can be converted to displacements (e.g. compressive and tensile force, strain, torque and vibration) may be measured by this DC/DC displacement sensor. Typical application areas are the measurement of displacement and strain on machines, servo systems, vehicles, on test plants, in civil engineering and tunnel construction. An integrated maintenance-free electronic and a high-level DC output signal provide an easy handling without any problems. Displacement sensors of series 87240 convert a displacement into an analog electrical signal. They consist of a differential transformer with moveable core, an oscillator and a demodulator. These components are integrated and encapsulated in a cylindrical housing made of stainless steel. The sensors are energized by DC voltage, which is converted to AC by the oscillator and brought to the primary coil of differential transformer.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

These displacement sensors are potentiometric displacement sensors used for direct measurement, testing and monitoring of mechanical displacements. The spring-loaded control rod eliminates the need of coupling with the measurement object. A prerequisite for a very long life duration of the devices is a parallel alignment of the motion direction of the measurement object and the rod. Areas of application are: Displacement on: —Electromagnets —Hydraulic cylinders —Switches and buttons Measurements of: —Deformation —Bending —Press-fits —Feed strokes Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. FEATURES: —Measurement ranges: 0 ... 10 mm to 0 ... 150 mm —Non-linearity up to 0.05 % F.S. —Resolution 0.01 mm —Follower roll on request —Optional with internal spring

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors using the principle of the differential transformer (LVDT) can be used to measure displacement and, indirectly, magnitudes that can be converted into displacements such as force, pressure, strain, torque, vibration and so forth. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development, etc.). Applications include measuring, controlling, regulating and monitoring both slow and fast movements between machine parts, measurements of position and positional changes of components and structural foundations, servo regulators, valve and robot controllers, growth measurements and so on. Their design is robust - the internal coils and electronics are potted - as a result of which the sensors can easily withstand shock and vibration.

Request for a quote

EDDYLAB GMBH

Germany

The SM series offers ultimate reliability and precision in a small size, and is designed for industrial and lab use. With a measuring range from 2 up to 200 mm and various configuration options (mechanics, protection class, temperature range, linearity) the SM series ensures to have a suitable measuring system for every application. ■ High precision and linearity ■ Various configuration options ■ Push-rod guided and unguided, spring loaded ■ Stainless steel housing ■ Linearity up to 0,10 % ■ Measuring range 2...200 mm

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The reliability and safety of a sensor is extremely important, particularly in high-pressure applications such as water-jet cutting equipment and hydraulic circuits. The dynamic loading encountered in these applications requires the use of sensors that are specially adapted for high pressure ranges. It is exactly these tough requirements that are satisfied by the model number 8221 sensor. With dynamic pressures, for example, an unlimited number of measurements can be taken if the pressure lies within the range from 0 ... 70% full scale. Range of applications: —Laboratory —Production —Aeronautical engineering —Cutting equipment —Hydraulics —Test benches Specific characteristics: —Measuring ranges from 0 ... 1000 bar to 0 ... 5000 bar —Accuracy ≤ 0.2 % F.S. —Medium temperature range from - 30 °C ... 120 °C —Ideal for dynamic measurements —Protection class IP66 —Digital calibration with the option of integrated instrumentation amplifier

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This transducer can be used anywhere thanks to its small size. Designed to work without a measuring chamber (uses a flush front diaphragm instead), this transducer is ideal for any measurements where the material to be measured may leave problematic residues. The range of suitable applications is even greater thanks to a choice of screw-on or weld-on adapters. Areas of use: Bottling plants, food industry Mixing facilities for the chemicals industry Pharmaceuticals Cosmetics industry Bioengineering These miniature pressure transducers are made entirely of titanium and therefore have outstanding resistance to corrosion. These convert the pressure-induced deflection of the diaphragm into a change in electrical resistance, which can be amplified, measured and processed by external electronic circuitry.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

High-precision pressure sensors from the 8201 series provide exact measurements while exhibiting very little sensitivity to mechanical stresses. Their application therefore goes well beyond research and development laboratories. They are also outstandingly suited to industrial use in quality assurance or for measurement and control tasks in production. Their robust mechanical and electrical construction guarantees good long-term stability and high reliability, while being resistant to aggressive media – which can be measured in liquid or gaseous states. The structure of the sensors includes no mechanical moving parts, which is why they show so little sensitivity to impact and vibration. The pressure sensors can be configured with options to suit the user. Standard types are available ex-stock, and customized customer versions can also be provided. Aeras of application are: —Research and developmemt —Test rigs —Mechanical engineering —Plant control and monitoring

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Model number 8201 precision pressure sensors are robust, economical, and are available in standard measuring ranges. Their good technical specification and high reliability make them optimum for measuring pressure in all fields of machine construction, process technology, as well as in measurement and control technology. The pressure transducers are easy to handle and immune to shock loads and vibrations as they are designed without moving parts. All pressure transducers without an internal amplifier have a standardized output signal of 1.0 mV/V. This enables the user to change a transducer in a measuring chain as liked without following readjustment of the electronic. Customized designs are available on request. Aeras of application are: —Hydraulic or pneumatic machines —Mechanical engineering —Plant control and monitoring The measuring element of the precision pressure transducer consists of a diaphragm.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

With its rugged housing and a stainless steel sensor element, the transducer is particularly robust and ideally suited to the harshest environments. This also means that the sensor can be installed anywhere with no effect on the measurement signal. The built-in instrumentation amplifier converts the sensor signals into noise-immune voltage signals or current signals that can be transmitted over relatively long distances. For high viscose materials, a front-level membrane M12 x 1 is available, and with this disruptive dead volumes can be expelled. The sensor has a small protected hole on the rear to allow measurement of atmospheric pressure (measurement type relative). For the absolute measurement option, the applied pressure is measured with respect to an enclosed vacuum. As an electrical connection, a DIN 43650A valve connector or an M12 x 1, 4-pin connection is available.

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

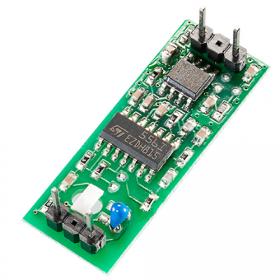

The calibrated humidity module with integrated NTC temperature sensor is a high runner among the B+B sensor transducers. The signal of the humidity sensor is transformed into a voltage output, whereas the NTC signal is analogue.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The DAP Series incorporate a heated sensor tip, which limits the potential for sensor damage relating to the membrane, resulting from installation or removal of the pressure transmitter. The Gneuss patented heated sensor tip allows the sensor to be easily removed from a “frozen” melt without any problems. The diaphragm is not damaged when the polymer contracts. The DAP has revolutionized the handling of critical medias, for example PC, PMMA or ABS.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

A CAN controller at the output enables integration into the CANopen network. According to CANopen Application Layer and Communication Profile, CiA Draft Standard 301, Version 4.1 and "Device Profile for Encoders CiA Draft Standard Proposal 406 Version 3.0" and CANopen Layer setting Services and Protocol (LSS), CiA DSP 305.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The angle transducers have a magnetic scanning according to the HALL principle. Due to the robust design, critical and interference-free applications in harsh environments can be realized. They have a robust housing (wall thickness > 5 mm) made of aluminium or stainless steel, shaft and ball bearing made of stainless steel, shaft with flattening, rotor with shaft and permanent magnet mounted in prechamber, sensor circuit consisting of ASIC with Hall elements and interface electronics housed in closed main chamber. Two models are available: For low and high temperature applications. The model for low-temperature use is equipped with a special grease for bearings and shaft seal. Seals and shaft seal are made of PTFE. Cable gland with clamping jaw pressure screw and silicone seal. The model for high temperature use is without shaft seal. Under the rear cover there is a signal changeover switch (CW/CCW). On the side there is a preset button (4 mA) placed under a screw plug.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case either in seawater resistant aluminum or in stainless steel - shaft in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - optional potting against water jets (IP 69K) - electrical connections via cable leads with inspection plug.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case with wall thickness of 5 mm either in seawater resistant aluminum or in stainless steel - shaft and ball bearings in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - optional potting against water jets (IP 69K) - electrical connections via round plug or lead exit.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust aluminium or stainless steel housing (wall thicknesses up to 5 mm) - stainless steel shaft and ball bearing - ball bearing with Simmer ring, rotor with shaft and permanent magnet mounted in pre-chamber - sensor circuit consisting of ASIC with Hall elements and interface electronics in enclosed main chamber - housing protection type IP 69K additionally cast - electrical connection via cable (open cable ends).

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position and revolutions by means of Hall sensors - multiturn version with absolute transmission for up to 4096 revolutions - data output plus parameterisation and diagnosis via Profibus-DP. Robust housing manufactured from seawater-proof aluminium or stainless steel - stainless steel shaft - ball bearing with radial shaft seal - sensor circuit consisting of ASIC with Hall elements - electrical connections via the connecting cap with threaded cable connections. The absolute encoders are designed for direct connection to the PROFIBUS-DP. The interface is implemented with the SPC3 Siemens PROFIBUS controller. The protocol corresponds to DP-Slave Class 2 functionality in accordance with Profibus profile for encoders, No. 3.062, and is described in detail in the TRD 12770 user manual. The TRD is mechanicallly and electrically compatible with the electro-optical encoder CRD.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

A positive mechanical connection between the customer shaft and the sensor shaft ensures that the magnet of the sensor shaft accurately reproduces the rotation of the customer shaft. The TBE measures one revolution, i.e. a maximum of 16,384 steps/revolution. With the trailing absolute gear, the TRE rotary encoder achieves a measuring range of up to 4096 revolutions. The zero point and the code progression can be set or changed via the inputs 'Set input' and 'Codevelauf' (each input circuit E1).

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

Melt Pressure Transducer with Integrated Amplifier The DAI Series offers – in addition to maximum reliability – improved user friendliness in the form of an Auto-Zero Function for local or remote configuration. These models offer mA and mV output signals for further processing. The popular and most commonly used 2-wire and 4-20mA configuration provide unequalled interference in critical environments.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers work according to the principle of the differential choke (inductive half bridges). They consist of two coils which are encapsulated in a Mu metal cylinder in a sealed and vibration-proof manner. A Mu-metal plunger causes an opposite induction change in the two coils when displaced by the hollow coil body. The displacement transducers are designed for an oscillator frequency of 10 kHz. Power supply and signal conditioning are provided by external module modules.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

With the DAIX Series, Gneuss now has an explosion proof pressure transducer available. This melt pressure transducer is intrinsically safe. The uncompromising development of the DAIX provides an excellent choice for Ex-areas, complimenting years of tried and tested Gneuss products.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The DTA defines the industry standard in combination with temperature measurement. One process connection suffices to measure both values. The unit excels in its high quality workmanship and cost efficiency. Its absolute reproducibility and stable measuring values contribute to our measurement accuracies.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

Pressure Transmitter with Integrated Amplifier and Integrated Temperature Measurement The DTAI first of all offers the user the comfort of operating a DAI in combination with temperature measurement. One process connection suffices in order to measure both values. These model offers mA and V output signals for further processing. The popular and most commonly used 2-wire and 4-20 mA configuration provide unequalled interference in critical environments. Liquid filled measuring system Maximum reliability through new membrane technology Standard G-coating to counteract adhesive materials Combined pressure and temperature measurement Robust design with G-Armor flexible components Applications with process medias of up to 400°C (750°F) possible Pressure ranges from 0-50 and 0-2.000 bar (0-725 to 29,000 psi) available Interference resistant signals over long distances Stable output signals

Request for a quoteResults for

Transducer sensors - Import exportNumber of results

59 ProductsCountries

Company type