- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- throttle valve

Results for

Throttle valve - Import export

CIC - KLAUS CZERWONKA

Germany

Throttle valves and throttle check valves in stainless steel for applications in aggressive environments, food or pharmaceuticals. Available in sizes 1/8 to ½". Larger dimensions on request.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Throttle valves and throttle check valves made of aluminum in block form in sizes M5 to ½. Individual control characteristics are available on request.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Throttle Valves for In-Line Assembly DV ▪ Throttle and shut-off the flow of liquid media in both directions ▪ Designed for in-line assembly with female BSP, NPT and SAE threaded connections ▪ Graduated turning knob and coded spindle to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: up to 350 bar / 5000 PSI Throttle Valves for Manifold Mounting DVP ▪ Throttle and shut-off the flow of liquid media in both directions ▪ Designed for manifold mounting with either 4 or 6 mounting holes ▪ Graduated turning knob and coded spindle to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: up to 350 bar / 5000 PSI Throttle Valves for Cartridge Assembly DVE ▪ Throttle and shut-off the flow of liquid media in both directions ▪ Designed for direct installation into...

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Throttle valves, check valves, quick exhaust valves, manual slide valves

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 1, clamping direction G with throttle valve without switch rod with long clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 1, clamping direction G with throttle valve with switch rod without clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 1, clamping direction G with throttle valve with switch rod with clamping lever with contact bolt max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 2, clamping direction G with throttle valve without switch rod without clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 2, clamping direction G with throttle valve with switch rod without clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 2, clamping direction G with throttle valve without switch rod with long clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 1, clamping direction G with throttle valve without switch rod without clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 1, clamping direction G with throttle valve with switch rod with long clamping lever max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 2, clamping direction G with throttle valve without switch rod with clamping lever with contact bolt max. 70 bar, as per data sheet B1.8268

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

size 1, clamping direction G with throttle valve without switch rod with clamping lever with contact bolt max. 70 bar, as per data sheet B1.8268

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Application: E-gas, idle speed control The information detected from the pedal sensor are transmitted to the electric motor-driven throttle valve positionier via control and correction electronics. The current throttle valve position is measured by an integrated or adapted angle sensor. The idle controller regulates independent of the load the idling speed or the engine through the throttle position. This leads to an optimised fuel consumption. Automotive Applications.pdf For more information please contact: automotive@novotechnik.de, +49 711 4489-222

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Compact, non-contacting NOVOHALL rotary sensor in redundant version for automotive applications areas such as carburetor, throttle, EGR valves, transmission gear or accelerator RSC3200 e 01.pdf Data sheet Automotive-Applications.pdf

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Application: Motor Management Electronic pedal sensor modules comprise of an accelerator pedal, angle sensor, and mechanics for simulating the driver's traditional sense of the accelerator pedal. When the accelerator pedal is pressed down, the pedal sensor transmits information to the control electronics. Based on this information, the position of the throttle valve is calculated. Automotive-Applications.pdf For more information please contact: automotive@novotechnik.de, +49 711 4489-222

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACI INDUSTRIEARMATUREN GMBH

Germany

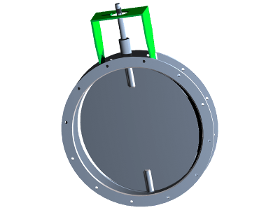

Throttle valve type LINA Use:

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

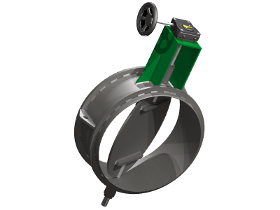

Throttle valve type ELA Use: The ELA valve was designed to be welded into an existing conduit. When properly installed, it guarantees a 100% airtight connection – without the need for additional sealing material. ELA is therefore able to also regulate and block „critical“ and dangerous media (that should not be allowed to penetrate to the outside). ELA is also the „easy way to regulate air.“

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

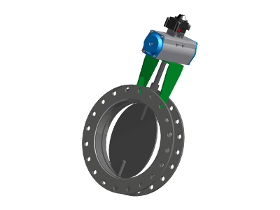

Throttle valve type FINJA Use: The FINJA flange valve was designed for use in PN and ANSI applications. It is the „big sister“ to our RIA wafer valve, and is in every way equal to the RIA in terms of durability, robustness and safety. Owing to its customized combination of materials and its configuration, FINJA is able to reliably satisfy your every requirement. Like all our valves, we can “automate” FINJA using any drive system commonly available on the market, together with suitable accessories.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Throttle valve type RIA Use: RIA is specially designed for use for flue and exhaust gases up to 1100°C. Depending on specifications, we can supply RIA in various, ready-made configurations, or we can adapt it to precisely suit your specific needs. RIA has an Integrated ISO interface. This allows for direct mounting without the need for an additional console – which means the RIA can be automated quickly and easily later on. RIA is very robust, durable and requires little maintenance. With its safe and proven design, RIA guarantees high system availability even under extreme conditions.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Pressure Compensated Throttle Check Valves PNDRV ▪ Throttle and shut-off the flow of liquid media in direction A-B (free flow in reverse direction) ▪ With pressure compensating feature via built-in compensating piston ▪ Designed for in-line assembly with female BSP, NPT and SAE threaded connections ▪ Graduated turning knob to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: 210 bar / 3000 PSI

Request for a quote

ERC ADDITIV GMBH

Germany

ERC Throttle/Butterfly Valve Cleaning Spray breaks down stubborn impurities in the carburettor system and prevents major repairs. THE EFFECT Deposits and impurities in the intake and throttle valve area impair the function of the carburettor system and increase the risk of corrosion and expensive repairs. THE ADVANTAGES AT A GLANCE - Removes soiling in the intake and throttle valve area - Cleans grease, dirt, and oil residue, as well as rubber abrasion off of metal surfaces - Can be used on (carburettor) linkages, cable wire passages and metal bearings

Request for a quote

EISELE GMBH

Germany

- Short design (exhaust-side throttle) - Adjusting screw with knurl - Whitworth pipe thread - VS seal rings - Material: brass nickel-plated, Al black anodized, KST - Type: Cone-type throttle - Allowable medium: Air - Temperature range 14 to 158 °F (-10 to +70 °C) - Working pressure range 7 to 145 psi (0.5 to 10 bar)

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

With the FPM (once F&G) explosion-proof low voltage motors, we offer you a complete programme of safe, reliable, durable and economically viable motors in protection IP 54 to IP 65, and Ex d and Ex de. All motors are also available as special versions to suit your individual requirements. The quality control system which is certified to DIN/ISO 9000, guarantees a consistent high level of quality. But there''s even more: As an environmentally friendly company, ATB Motorentechnik GmbH is also certified according to the EU-Enviornmental Audit (EEC 1836/93). We supply from our existing stock Kalefeld F&G- flameproof motors / hazardous motors Ex de IIC T4 High Efficiency IE2 in frame size 80 - 200 ( 2 and 4 -poles ) 0, 75 - 37 kW. All motors on stock are with Ptc thermistors. Other frame sizes and versions are available within 6-8 weeks after receipt of order . FPM Explosion Proof Motors / hazardous motors available in IE1 and IE2 High Efficiency Compact Drives Have you ever been faced with the situation where the drive speed cannot be changed, because an explosion-proof motor is used and installation of a frequency inverter in the electrical control room is too complex? The solution is a motor with an integral frequency inverter! Compact motor type CD 112 M-4I. With this design, the motor can be directly installed and the drive speed can be controlled Voltage: 380 to 500 V Performance range 0,55 - 11 kW Variable speed drive system for use in Zone1 with explosive atmospheres Spatial integration of flameproof enclosed motors (CD series) in a standard version with specially adapted frequency inverters derived from mass produced standard models Resonance effects in the drive incomers are avoided by spatial integration, as only one sinusoidal supply connection is available. This means that filtering which is required for installation of an external inverter is not required This drive fulfills the highest demands in the area of control engineering, with overload, smooth running, etc., as a result of the vector control technology applied The integrated PID controller simplifies the closed-loop process control The Bus technology which is available allows optimum adaption to suit the work process. The frequency inverter module can be retrofitted for all PTC thermistor motors of the CD series, from frame size 80 - 112 The fixing dimensions are standardized. It is therefore possible to exchange the motors (for example Ex e) with this compact drive in many applications The payback on investment is achieved by the savings in energy costs Mechanical control with throttle valve controls or bypasses can be easily replaced. The efficieny of your installation improves significantly

Request for a quoteResults for

Throttle valve - Import exportNumber of results

26 ProductsCountries

Company type