- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermoplastic polyurethane

Results for

Thermoplastic polyurethane - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

Rubber-to-metal bonding Our adhesive build-up provides strong bonding between our metal carrier and your rubber. With our know-how, we are able to bond a wide variety of compounds such as NBR, CR, EPDM, SBR etc. for you. Plastic-to-metal bonding Whether PC (polycarbonate), PVC (polyvinyl chloride), ABS (acrylonitrile-butadiene-styrene), CAB (cellulose acetobutryate), PP (polypropylene), TPU (thermoplastic polyurethane), PA (polyamide) and polyolefinic plastics or other thermoplastics as well as duroplastics - we ensure that you achieve optimum adhesion between the plastic and our metal carrier.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Thermoplastic injection-moulded polyurethane (TPU) based on polyesterpolyol, diisocyanate and glycol. This is vibration-absorbing, non-marking, non-staining and highly abrasion-resistant, while also providing good floor preservation. The tread is also resistant to a wide range of aggressive substances, although it has only limited resistance to hot water or steam.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Fullsan is the new product line of homogeneous, thermoplastic, polyurethane belts from Forbo Movement Systems. All Siegling Fullsan belts are protected from contamination by oil, grease, moisture and bacteria. Siegling Fullsan belts are very easy to clean and ideal for exceptionally hygiene-critical applications (dairy products, dough preparation, meat and poultry processing and other food-related areas).

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

For the majority of standard castors, either the tread or the steel bracket is not designed for frequent contact with water or high levels of air humidity or steam. Blickle stainless steel castors, on the other hand, provide corrosion protection in every area, including the high-quality chromium-nickel steel bracket, the synthetic wheel centre, a selection of treads made from rubber, thermoplastic polyurethane and nylon and the various bearings used. This is relevant for wet areas and environments with strict hygiene requirements, such as the food industry.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

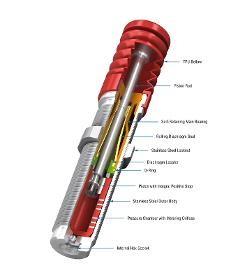

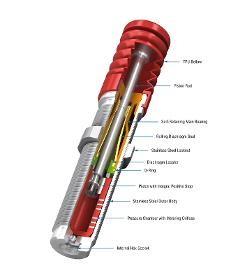

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 136 Nm/cycle Stroke 25.4 mm Hermetically sealed and rustproof: The Protection series PMCN is also available in a stainless steel design. This is or particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don't stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HFP BANDSTAHL GMBH & CO KG

Germany

In the field of plastics we offer metal strips with PVC plastisol and/or organosol coatings, as well as polyamide plastics. PP (polypropylene), PE (polyethylene), PC (polycarbonate), PET (polyethylene terephthalate) and PLA (polyactide), TPE (thermoplastic elastomer), TPU (thermoplastic polyurethane) and others. These can be produced with a layer thickness of 5-200 μm Depending on the plastic, higher layer thicknesses can also be achieved. In addition, most plastics can also be equipped with antibacterial properties; of course in all colour variations. Although a one-sided coating more common, we are able to apply the same and/or different plastic adhesives for both sides.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 41 Nm/cycle Stroke 12.5 mm Hermetically sealed and rustproof: The Protection series PMCN is also available in a stainless steel design. This is or particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don't stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 136 Nm/cycle Stroke 25.4 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 41 Nm/cycle Stroke 12.5 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 20 Nm/cycle Stroke 12.5 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

We accompany you with our design and development from the idea to series production! We process all common thermoplastics for you. Besides polyurethane, these are mainly: PE (polyethylene), PA (polyamide), PP (polypropylene), POM, ASA, TPU, PP, TPE as well as glass fiber reinforced plastics. Advantages of the injection molding process are low unit costs with high batch sizes. Before an injection mold is ordered, we build view samples for you as laser-sintered elements or by means of 3D printing. In this way, the desired part can already be viewed without having to spend a lot of money. Our machines inject molded parts from 5 to 6000 grams.

Request for a quote

OSW ESCHBACH GMBH

Germany

Feature: — excellent abrasion resistance and durability — resistant against slurry and many other chemicals — excellent tensile strength — minimum maintenance — extremely resistant to aging and ozone and UV — Cold-resistant up to – 40 ° C — Heat-resistant up to + 100 ° C — minimum friction loss because of very smooth inner lining — minimum elongation Construction: — inside: very smooth for minimum friction loss — jacket of 100 % high tenacity synthetic polyester yarn, circular woven in special construction for maximum tensile — completely embedded in high-quality thermoplastic polyurethane (TPU), is forced through the jacket in the extrusion process (standard colour: black; others on request), provides optimum protection of the jacket — outside: smooth, excellent abrasion resistance

Request for a quote

OSW ESCHBACH GMBH

Germany

Feature: — excellent abrasion resistance and durability → suitable for extreme conditions — excellent tensile strength — easy cleaning and disinfection — extremely resistant to aging and ozone and UV resistant — temperature resistant from – 50 ° C to + 75 ° C — minimum friction loss and minimum elongation Construction: — inside: very smooth for minimum friction loss — jacket of 100 % high tenacity synthetic polyester yarn, circular woven in special construction for maximum tensile — completely embedded in high-quality thermoplastic polyurethane (TPU is suitable for drinking water), is forced through the jacket in - the extrusion process (standard colour: blue), provides optimum protection of the jacket — outside: smooth, excellent abrasion resistance Approvals / Certificates: — KTW-Approval Cat. A — DVGW W270 — BS6920-1:2000 (WRAS)

Request for a quote

OSW ESCHBACH GMBH

Germany

Feature: — excellent abrasion resistance and durability → suitable for extreme conditions — excellent tensile strength — easy cleaning and disinfection — extremely resistant to aging and ozone and UV resistant — temperature resistant from – 50 ° C to + 75 ° C — minimum friction loss and minimum elongation Construction: — inside: very smooth for minimum friction loss — jacket of 100 % high tenacity synthetic polyester yarn, circular woven in special construction for maximum tensile — completely embedded in high-quality thermoplastic polyurethane (TPU is suitable for drinking water), is forced through the jacket in the extrusion process (standard colour: blue), provides optimum protection of the jacket — outside: very smooth with extruted holding strap with loops Approvals / Certificates: — KTW-Approval Cat. A — DVGW W270 — BS6920-1:2000 (WRAS)

Request for a quote

VOELPKER SPEZIALPRODUKTE GMBH

Germany

Effective lubricant and dispersing agent in transparent engineering plastics such as PET/PBT and in reinforced polypropylene (PP); lubricant, release agent and dispersing agent in polystyrene (PS), polyoxymethylene (POM) and nylon (PA, PA6, PA66); external lubricant for rigid PVC profiles; lubricant, release agent, slip agent and anti-fog agent in thermoplastic polyurethane (TPU), lubricant and anti-blocking agent in polymethylmethacrylate (PMMA).

Request for a quoteResults for

Thermoplastic polyurethane - Import exportNumber of results

16 ProductsCountries

Company type