- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- textiles - machines & equipment

Results for

Textiles - machines & equipment - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Large machinery parts,Textile machine accessories.China cnc machining workpiece

Request for a quote

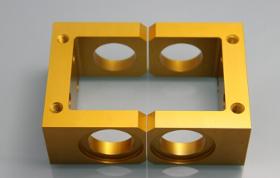

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This parts is made by aluminum, after 3-4 axis machining, then, going golden anodize,it is used in the external support of the machine.

Request for a quote

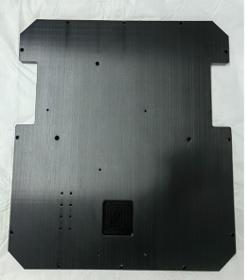

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Large machinery accessories.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Bow and skew detection and control The Orthopac FMC automatic straightener is the heart and core of the Orthopac. The device consists of an optical scanning system and electronic control for distortion correction. It is used primarily to detect and log residual distortions in the exit end of a system, e.g. with the stenter. Thread density can be determined at the same time. It can also be connected to external straightening machines then serving them as control unit.

Request for a quote

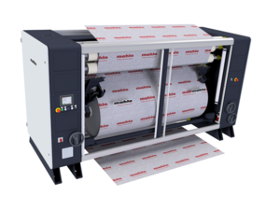

MAHLO GMBH & CO. KG

Germany

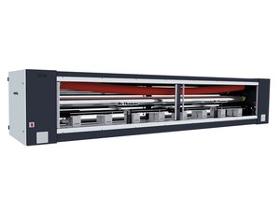

Heavy-duty weft straightening The heavy duty version. High demands due to large product widths (e.g. carpet) or dimensionally stable textiles with defined skew settings (e.g. denim) require a more solid configuration. The frame, bearings and rollers are designed for high loads. Available with up to 5400 mm working width.

Request for a quote

MAHLO GMBH & CO. KG

Germany

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Removing all types of distortions The fusion of pin wheel and roller straightening technology perfectly combines the advantages of both technologies and provides amazing straightening results. It provides reliable, quick distortion correction also for asymmetric web distortion. An infinitely variable unclipping roller minimises residual bow and edge distortions. The intelligent drive station with special voltage control for smallest product distortion activates or deactivates automatically (e.g. in case of blockages). A bypass function is available at the push of a button for products that cannot be straightened with the pin wheel.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Removing irregular distortions Asymmetrical distortions (wavy, S-shaped, etc.) in textiles have always represented a huge challenge in the textile industry. A special straightening approach is needed particularly when the straightening process does not take place in combination with a stenter (e.g. before decatizers, digital printing systems, etc.). To restore the warp and weft threads to their original state, the Orthofact RMB generates a defined lateral tension using freewheeling, inclined pin wheels. This cross-tension stretches the warp threads. The resultant force controls the freewheeling pin wheels, since the weft threads will always seek out the shortest path from selvedge to selvedge. Distortion, no matter whether wavy or S-shaped, will be corrected.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

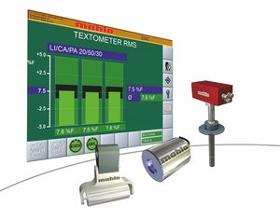

MAHLO GMBH & CO. KG

Germany

Control of thread density / course density / basis weight The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count. A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Condensate temperature control The Atmoset SMT regulates the residual moisture of the tissue with steam-heated cylinder dryers. The deviation of the condensate temperature from a preset setpoint is used to directly calculate the amount of energy required for drying. The heating output is optimised according to the product. The Atmoset SMT enables a stable and effective drying process. The optimal degree of drying is always reached, regardless of the weight of the product or the web speed.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Keeps web safely on track Drifting of the product web lateral to the running direction of product is unavoidable in some stages of textile finishing. The Ceremat system brings the product back on the right path. Applicationspecific variants are available.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Infrared pyrometer The Thermosense HP270 is used for non-contacting temperature measurement in driers and stenters and records the temperature of running product webs. The sensor is temperature-resistant up to 270 °C. It can therefore be mounted inside driers.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Ionisation of the air The Antistat AMW ioniser for trouble-free processing of synthetic materials and of textiles with high charge separation. By ionising the ambient air, the electrostatic charge is diverted from the product sheet. Antistat AMW can be used at high or low speeds.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Reflexion of infrared light Automatic width measurement on a running product web. IR LEDs used in reflective mode continuously and precisely determine the product width. The sensor module only needs to be attached on one side of the product. The compact design allows it to be installed even in the tightest mounting spaces. Retrofitting is possible virtually anywhere.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Fine-tune straightening for heavyweight fabrics The special strength of the Orthopac GMFRC is the extremely high straightening accuracy at relatively small distortions. Thanks to reinforced components, it is ideal for processing really wide, heavyweight materials such as denim. The compact straightening unit is equipped with a skew and bow roller as standard. This arrangement allows for very fine adjustment of the straightening effect while permitting small device dimensions.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Fine-tune straightening of residual distortion This model represents a compact fine-straightening system for the correction of residual distortions. The special strength of the Orthopac MFRC is the extremely high straightening accuracy at relatively small distortions. The compact straightening unit is equipped with a skew and bow roller as standard. This arrangement allows for very fine adjustment of the straightening effect while permitting small device dimensions. Available with hydraulic or electrical straightening roller adjustment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAHLO GMBH & CO. KG

Germany

Portable moisture meter The Textometer DMB is a mobile handy device for measuring moisture on textile webs and bobbins on a wide variety of versions. It determines the moisture content of raw materials, semi-finished products and finished products precisely and quickly.

Request for a quote

MAHLO GMBH & CO. KG

Germany

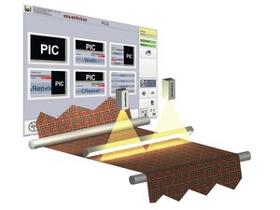

Pattern and distortion control The leading pattern detection system using camera technology. The repetitions of printed, woven or tufted patterns are evaluated according to certain algorithms and are used for measuring, correcting and evaluating distortions and patterns. The system uses one or two cameras, depending on the width of the product, to detect the position of the pattern and automatically and continuously determine the pattern repeat, as well as the product width, and together with a straightening machine align the product distortion based on the recognized pattern.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

for fibrillating films and fibers

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

The aluminum lags are produced precisely for all machine types. Optimized processing techniques tailored to the material ensure that the pins are securely seated. Thanks to modern CNC technology, the needle arrangement and angle precisely meet the requirements of the application. For a high-quality replacement of the original equipment at an optimal price-performance ratio, we are looking forward to your inquiry! A questionnaire is available below, alternatively, send us a sketch. The specification of machine type and desired needle density often suffice.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Complete cylinders: they consists of a base body covered with aluminum or laminated wood spiked lags. These rollers are used to open or tear fibers as well as recoil and draw rollers in feeders.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Needled or perforated parts in any design, produced according to customer requirements

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our ovens and line concepts for bonding and finishing of nonwovens stand for maximum production output, low energy consumption and highest precision regarding temperature distribution, air circulation and coating application. We can offer different application systems such like foam impregnation units, padders, spray cabinets, powder scattering units, coating heads and many others. In addition, we can offer complete lines like airthrough doublebelt thermofusion ovens, airthrough dryers for lightweight nonwovens, airthrough dryers for high speed spunlace lines for wipes or wetlaid nonwovens. Our customers are active in the fields of hygienics & medicine, construction & geotextiles, clothing & comfort, cleaning & care, automotive & transport, filtration and many more.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The BRÜCKNER hotflue is the heart of a continuous dyeing range and depending on the customers’ requirements it can be supplied with oil or gas heating. Due to the intelligent drive concept and a sophisticated air flow control an exact shade homogeneity is achieved across the length and the width of the fabric. Tailing and migrations are prevented and the dyeing results are 100% reproducible. This line is appropriate for all woven fabrics, particularly shirting and trouser fabric as well as home textiles such as bed linen. Benefits are among others best dye uniformity over the complete length and width of the fabric, no tailing, no migration, creasefree production, 100% reproducible dyeing results, minimum consumption of thermal and electrical energy, tailormade solutions for a maximum productivity even with small quantities, easy access for cleaning and maintenance due to large doors.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Finishing on a sanfor line provides the fabric with a more stable structure, a silklike shine, a smoother touch and minimum residual shrinkage. The rubberbelt compacting line is made for the sanforisation and compacting of woven fabric and some kinds of knitted fabric, in combination with a felt belt calender the fabric gets on these lines additionally a special touch. The benefits are among others optimum residual shrinkage due to the hightech drive concept, stabilisation of the fabric structure, silklike shine, soft fabric touch, absolutely constant shrinkage due to a new automatic shrinkage control system available as option, production speeds up to 100 m/min are possible, extended service life of the rubber belt due to the larger diameter of the compacting rollers and an optimised rubber belt cooling system, integrated menudriven rubber belt grinding process, minimisation of vibrations, all bearings arranged outside of the wet area and therefore no corrosion.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The relaxation dryer serves for the drying, relaxing and shrinking of knitted fabric in tubular and openwidth form but can be used also for the treatment of woven fabric. Residual shrinkage is reduced to a minimum and the fabric gets a very good dimensional stability across the length and width and a fleecy, soft and voluminous touch. Depending on the customer’s requests and the needed capacity, the dryer is available with one, two or three fabric passages. This dryer is mainly used to finish articles made of natural fibres such as cotton, viscose and wool but also of blends thereof or blends with elastane, polyamide or polyester. Such fabric qualities are mostly further processed for underwear (ribware), nightwear (Interlock), polo shirts (Piqué), Tshirts (single jersey) or sweat shirts (fleece or sweatware). The residual shrinkage is reduced to a minimum and the fabric gets a very good length and width stability and a fleecy, soft and voluminous handle.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The stenter is the heart of textile finishing. It develops more and more into a multipurpose line for the production of technical textiles and other webshaped materials. Several thousands of BRÜCKNER stenters are in use all around the globe. Every day they are stentering, drying, heatsetting, functionalizing and coating incountable meters of the most different fabric types. Since many decades BRÜCKNER stenters stand for highest quality and performance and are producing sustainably and energyefficiently. The most important benefits of these stenter frames are highest drying performance and process control matching any type of fabric due to the technically mature and proven splitflow air circulation system, very homogeneous air flow and temperature distribution due to alternately arranged thermo zones, very low specific energy consumption, extremely robust chains, chain rails, pin bar carriers and clips, needing only little maintenance.

Request for a quote

SAMATEX GMBH

Germany

We offer a small variety of spare parts for the Autodoffing of Ringspinning machines such as Rieter G5/1, G5/2, G30, G33, K44, Zinser 319, 320, 321, 350, 421 and Marzoli.

Request for a quoteResults for

Textiles - machines & equipment - Import exportNumber of results

35 ProductsCountries

Company type