- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- textile industry

Results for

Textile industry - Import export

IGUS® GMBH

Germany

xiros® polymer ball bearing – now electrically conductive xiros® F180 polymer ball bearings offer protection against electrostatic discharge. In this type with ESD protection (Electro Static Discharge), the newsly developed ball bearing material xirodur® F180 is used. The new development is applicable up to +80°C and offers a long service life. Free of lubrication and maintenance. Electrically conductive (ESD protection). economical Lightweight. Industries:Semiconductor industry, handling, paper, textile and glass industries, etc., furniture industry etc. d1 [mm]: xiros® material - Material data xiros® polymer ball bearing design, applications, development and testing xiros® chemical resistance xiros® F180 polymer ball bearings offer protection against electrostatic discharge. In this type with ESD protection (Electro Static Discharge), the newsly developed ball bearing material xirodur® F180 is used. The new development is applicable up to +80°C and offers a long service life. Free of lubrication and maintenance. Electrically conductive (ESD protection). economical Lightweight. Industries:Semiconductor industry, handling, paper, textile and glass industries, etc., furniture industry etc. PA-cage made of xirodur® F180, stainless steel balls -40°C to +80°C d1 [mm]:

Request for a quote

EMBRO GMBH

Germany

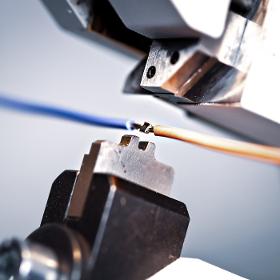

The semi-finished products manufactured by Embro GmbH are optionally available with an electrical connection. In addition to the many possibilities of placing different elements on carrier materials with special embroidery processes, Embro offers splicing or soldering techniques for perfect and cost-effective connections. The parts are crimped or soldered together as standard. The introduction of thermal switches, NTC or other cable solutions is also no problem. Special connector solutions can also be implemented. This means that the textile semi-finished products are plug & play ready upon delivery. #service #contacting #b2b

Request for a quote

FORBO SIEGLING GMBH

Germany

Properties • laterally stiff • suitable for knife edges • Belt support: Slider bed (support rollers possible

Request for a quote

METO INTERNATIONAL GMBH

Germany

7-, 8- or 18-digit paginators with consecutive numbering, e.g. for labeling pieces in production in the textile industry. Also available as pneumatic tools.

Request for a quote

WEBER ULTRASONICS AG

Germany

From coloring in the textile industry to the processing of ballast water in maritime applications, the Flow-Through Cell is the chamber solution for flowing media and can be designed to meet specific requirements.

Request for a quote

FORBO SIEGLING GMBH

Germany

Textile Industry For decades Forbo Movement Systems has been accompanying the numerous developments in the manufacture of yarn and fabrics together with the textile machine manufacturers. The results are: Power transmission belts with thermoplastic tension members made of polyester and aramide as drive elements in yarn processing Cross-lapper belts with specially developed coatings New printing blankets for ideal printing results

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of open toothing, friction and rolling bearings, threaded spindles, hinges, guides on windlasses, ship´s cranes, underwater devices, offshore components or in wet areas of the textile industry Corrosion protection of moving parts subject to seawater in coastal and marine areas or constant influence of water Advantages and benefits Excellently suited as a waterproof special grease above and under water Highly effective due to optimum wear and outstanding corrosion protection Economical due to combined protective effect Lubrication of open toothing, friction and rolling bearings, threaded spindles, hinges, guides on windlasses, ship´s cranes, underwater devices, offshore components or in wet areas of the textile industry Corrosion protection of moving parts subject to seawater in coastal and marine areas or constant influence of water Advantages and benefits Excellently suited as a waterproof special grease above and under water

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

Centrefold plastic film is created by slitting blown film, which is closed on both sides, at the side or down the centre, as desired. It is basically folded flat film. Centrefold film can be used for a wide variety of packaging solutions. One good example is in the furniture industry, which uses centrefold film as furniture covers to protect pieces from dirt and dust. But centrefold film also plays a major role in product packaging in other areas such as e-commerce, the pharmaceutical industry and the textile industry. Centrefold film is mostly processed using machines – especially L sealers, for example. Centrefold film is one of the most common types of plastic film used in automatic packaging machines.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of most different materials sliding on resp. rubbing against each other like metals, wood, ceramics, rubber as well as paintable plastics For packing machines, sliding areas in the plastics and textile industry, rollers and chutes in the transport range, etc. Non-stick coating of all kinds of sealings and sealing areas to avoid sticking, squeaking of soft on hard materials (e.g. rubber on glass), for water-repellent impregnation of absorbing materials or as separating film for casting resin applications Advantages and benefits Thin, tack-free separating film with very good adhesive properties on prepared surfaces Best suitability for low-friction lubrication of all kind of materials in contact Colourless and odour-free antifriction coating with non-stick properties

Request for a quote

MAHLO GMBH & CO. KG

Germany

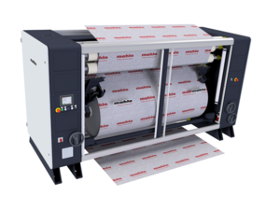

Removing irregular distortions Asymmetrical distortions (wavy, S-shaped, etc.) in textiles have always represented a huge challenge in the textile industry. A special straightening approach is needed particularly when the straightening process does not take place in combination with a stenter (e.g. before decatizers, digital printing systems, etc.). To restore the warp and weft threads to their original state, the Orthofact RMB generates a defined lateral tension using freewheeling, inclined pin wheels. This cross-tension stretches the warp threads. The resultant force controls the freewheeling pin wheels, since the weft threads will always seek out the shortest path from selvedge to selvedge. Distortion, no matter whether wavy or S-shaped, will be corrected.

Request for a quote

FORBO SIEGLING GMBH

Germany

With Siegling Transilon, the gap is often bridged between the classical conveying function from “A” to “B” and an active function in the production process. For example, in the textile industry our processing belts stack thin layers of web, in large bakeries they form balls of dough, in the wood industry they compress chip mat in the pre-press, in dairies milk is coagulated on the belts to form cheese. Here are just a few examples of process operations. Cross-lapping of web layers in the nonwoven industry. High production speed and acceleration of masses while the web is guided directly between the belts places extremely high demands on the processing belts.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Due to many successful projects we possess a wealth of experience in this field. In the following a selection of applications: special machinery, textile industry, automotive industry, aviation industry, special equipment manufacturing, packaging industry, power and drive technology, machine and plant engineering as well as shipping industry.

Request for a quote

PÜTZ GMBH & CO. FOLIEN KG

Germany

Grammage: 42,5 g/m2 - 120 g/m2 High density Polyethylene Spunbond. tearproof, nailable, dimensionally stable, sewable, water- and weather resistant, printable, punchable, perforable Pre-treatment (surface): different pre-treatments, partially with antistatic properties e.g..: Tyvek® Application: Carrier Bags Application: Food Industry, Graphic Arts Industry, Label, Textile & Household Industry

Request for a quote

PÜTZ GMBH & CO. FOLIEN KG

Germany

Thickness range: 100-500 µm calendered film made of Polyvinylchlorid Application Office Equipment Automotive, Pharmaceutical Industry & Healthcare, Engineering Use, Textile & Household Industry, Packing

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Calibrate and adjust mechanical yarn brakes for the textile industry The test specimen is inserted in the UUT, which is mounted on a pneumatic slide. By pressing a button, the candidate moves to the running belt drive. The sample is then tested in different locking positions, the switching of the individual Paramtersätze is realized via a rotary switch. In each latching position, IO / NIO statement about the GMV2 light mounted on the column is displayed visually. After passing the examination, the tray will open again and the next candidate can be inserted. A speed controller as well as an ON / OFF switch for the drive are also integrated in the switch box under the GMV2. The entire inspection unit is mobile and complained to a height-adjustable lifting unit. The GMV2 and connect the switch are also mounted height adjustable in the profiles.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

In the field of minimum application unit we can offer different application units such like floating knife, mini kissroll, knifeoverroll and screen or predosed kissroll units. These units offer the following advantages compared to a traditional padder process Lowaddon technology with a fabric moisture of 60 g/sqm, lower water consumption and thus high energy savings during the subsequent drying processes, low residual liquor (2.5 litres per metre working width) and thus fewer chemicals which have tob e disposed of during a batch change. Test can be carried out at any time on our test plant in our Technology Centre in Germany.

Request for a quote

FILTEC W. HERMANNS GMBH

Germany

TROL as niche product is mainly used as technical fabric and needle felt in the field of industrial dedusting and liquid filtration applications. Teperature resistance TROL® posses a 35 °C higher temperature resistence compared to conventional PP. Continuous temperature resistance is 125 °C, peak temperature is max. 135 °C (< 200h/year). Hydrolysis resistance TROL® consists of saturated hydrocarbon chains. Hydrolytic cleavage and corresponding deterioration of the polymer does not take place.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Textile industry - Import exportNumber of results

17 ProductsCountries

Company type