- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tests mechanical

Results for

Tests mechanical - Import export

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We plan, build and deliver turnkey test systems for electronic and mechanical components. For example, these are test benches for quality assurance, validation and production departments of companies in various industries. Our services include e.g.: - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design - Risk assessment and CE - Commissioning, service, maintenance at home and abroad

Request for a quote

HOCHRAINER GMBH

Germany

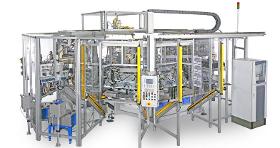

Rotary indexing assembly table for power window mechanism including testing station .

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

These displacement sensors are potentiometric displacement sensors used for direct measurement, testing and monitoring of mechanical displacements. The spring-loaded control rod eliminates the need of coupling with the measurement object. A prerequisite for a very long life duration of the devices is a parallel alignment of the motion direction of the measurement object and the rod. Areas of application are: Displacement on: —Electromagnets —Hydraulic cylinders —Switches and buttons Measurements of: —Deformation —Bending —Press-fits —Feed strokes Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. FEATURES: —Measurement ranges: 0 ... 10 mm to 0 ... 150 mm —Non-linearity up to 0.05 % F.S. —Resolution 0.01 mm —Follower roll on request —Optional with internal spring

Request for a quote

MOOG GAT GMBH

Germany

GAT torsion motors are supplied as individual components or as complete torsion system consisting of torsion motor unit, application-specific control electronic s and hydraulic supply. Comprehensive consultation services from concept planning phase to commissioning complement our portfolio. GAT torsion motors consisting of a basic motor and a GAT rotary union are designed for quasi-static, pulsating and dynamic loads. Speed and torque as testing parameters are controlled independently. The torsion test rig with mechanical torsion application allows the energy-efficient testing of components at relatively low investment costs. Using a hydrostatic torsion motor in the test rig creates realistic and consistent testing conditions leading to test results very close to real-life conditions.

Request for a quote

TEPROSA GMBH

Germany

In an environmental simulation, assemblies are subjected to defined environmental conditions to validate their behavior under those conditions. The variables of an environmental simulation test include climatic aspects such as temperature (cold, heat), the air conditions (humidity, wetness), mechanical influences such as dust, vibration, vibration or impacts, and corrosive environmental effects such as salty lift (salt fog). As an environmental simulation laboratory, we simulate these environmental conditions in our climatic chambers and climatic chambers, creating real conditions to investigate the long-term behavior of the test specimens in reality. Environmental simulation and thermal shock testing laboratory for electronic assemblies and printed circuit boards We specialize in performing environmental simulation and temperature shock testing of electronic and mechanical assemblies. With over ten years of experience with the requirements of the automotive industry and medical

Request for a quote

TEPROSA GMBH

Germany

We are specialized in performing thermal shock testing of electronic and mechanical assemblies and have a lot of experience with the requirements of the automotive industry and medical technology. On behalf of our customers, we perform environmental and climatic tests according to customer specifications and applicable standards, thus uncovering optimization potential. We will be happy to advise you with regard to your testing tasks and, together with you, transfer the entire testing process into a specification sheet. OUR OPPORTUNITIES 2-chamber system air-air Test chamber volume up to 130 liters Temperature range hot chamber 50°C to 200°C Temperature range cold chamber -80°C to -100°C Change between chambers <15 seconds Maximum test material weight 25 kg State monitoring of the test specimens during the test

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

High-precision pressure sensors from the 8201 series provide exact measurements while exhibiting very little sensitivity to mechanical stresses. Their application therefore goes well beyond research and development laboratories. They are also outstandingly suited to industrial use in quality assurance or for measurement and control tasks in production. Their robust mechanical and electrical construction guarantees good long-term stability and high reliability, while being resistant to aggressive media – which can be measured in liquid or gaseous states. The structure of the sensors includes no mechanical moving parts, which is why they show so little sensitivity to impact and vibration. The pressure sensors can be configured with options to suit the user. Standard types are available ex-stock, and customized customer versions can also be provided. Aeras of application are: —Research and developmemt —Test rigs —Mechanical engineering —Plant control and monitoring

Request for a quote

TAVRIDA ELECTRIC

Germany

Challenge To execute a pilot project at the Energisa distribution network operator in Brazil within a tight time frame. The customer needed to install 23 kV outdoor circuit breakers with protection at a newly erected substation. Solution Tavrida Electric supplied the Rec25 with substation mounting kit to meet the deadline and satisfy the customer’s requirements in terms of protection. The mounting kit was subjected to comprehensive mechanical tests including overweighting, wind load and seismic impact with successful results.

Request for a quote

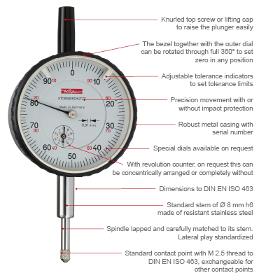

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The well thought-out design, accurate components and robust construction of our Precision Dial Gauge series offer reliability, durability and long working life. The standard features that enhance the quality across our entire product range are: Calibrations of all Dial Gauges are traceable to national and international standards. The final quality control for the whole series includes visual inspection and full mechanical functional tests. Supplied with Declaration of Conformity and Confirmation of Traceability. Materials and components selected specifically to ensure a long working life.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre compressed Packing set of expanded graphite with Inconel Matrix reinforcement and special PTFE coating Characteristics Ring Set made from special high temperature resistant yarn and pore filling cross section impregnation fulfills with a tested leakage rate of 8.4 x 10 -3 mbar · l/(s·m) the leakage criteria of VDI 2440 +400 °C with a maximum allowable leckagerate of 1 x 10 -2 mbar l/(sm) and is suitable for temperatures up to +300 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +300 °C Temperature with LiveLoading: t +300 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Control Valves Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Approvals TA Luft / VDI 2440 Certificate ISO 15848-1 CC1 ISO 15848 test was conducted with 20,000 mechanical cycles and 2 thermal cycles (RT, +200 °C) and passed with a leckagerate of 6.1 x 10 -4 mg/s/m.

Request for a quote

TEST GMBH

Germany

Universal Testing Machine for methodical component and materials testing for forces up to 100 kN. Fields of applications are everyday industrial procedures in rough environments as well as in laboratories, in the fields of research and development or teaching. This technically mature product for static tests with modern measurement and control technology, the suitable right accessory and the innovative testing software TesTWinner® meets all requirements of modern material testing. In addition the model is equipped with the TesTController 850. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes, and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

The testing machines of model series 215 were developed and built for applications with extremely small measuring ranges, below 0.1 Ncm, and highest precision. They are for example used in watch idustry or medical technology. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Vehicle safety test equipment Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Procurement of all materials Welding Full dimension check Mechanical engineering Pressure testing Leak testing with vacuum Surface treatment Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Busbar and circuit breaker vessel and containers in various designs Welding Full dimension check Mechanical engineering Pressure testing Leak testing with SF6 gas Documentation Acceptance

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZWICKROELL GMBH & CO. KG

Germany

Due to their design, Vibrophores have been used in the past solely as dynamic materials testing machines to determine durability with regard to fatigue life and fatigue limit, for example for fatigue testing to DIN 50100 (S-N curve) under tensile, compression, pulsating and alternating loads. The new generation of ZwickRoell Vibrophores can be used as both dynamic and full-fledged static materials testing machines that accommodate test loads up to 1000 kN. Typical applications are material fatigue tests and durability tests on standardized specimens and components (for example, piston rods, crankshafts, and screws) and production and quality control of components exposed to dynamic loads during their service lives, such as concrete and reinforcing steel, as well as quasi-static tensile and compression tests and fracture mechanics tests on CT and SEB specimens.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Fittings made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Casing made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

Optical inspection with the new stand-alone camera system allows for inexpensive and flexible testing of several production processes. Inspection with the high definition system camera (18/42 megapixels) is controlled and analyzed by a Microsoft Windows-based computer running the professional modus AOI-software. Characteristics Single system for the inspection of objects within an offline application (One Piece Flow). Combination of various inspection tasks such as SMD-THT-UV, bond inspection as well as laser solder inspection. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MCS42-SEL-AL is a cost effective camera-based AOI system. This solution is optimized for economical and flexible inline inspection of the several production processes. The small and inexpensive system comes with a 42 megapixel, high-definition industry camera and a PC equipped with the powerful modusAOI software whose development includes professional experience of two decades. Characteristics: Single system for inspection of objects. Combination of diverse application tasks in the THT area which take place before a wave soldering or selective soldering oven. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quote

SP SÜDDEUTSCHE PRÜFANLAGEN GMBH

Germany

For measuring mechanical properties of metallic materials

Request for a quoteResults for

Tests mechanical - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Testing of products and materials (2)

- Flanges (2)

- Laser - cutting and welding machines (2)

- Machinery and equipment, used and reconditioned (2)

- Monitors, computer (2)

- Sensors (2)

- Supply vessels (2)

- Electric transformers, converters and rectifiers (1)

- Foundries - machinery and installations (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Mechanical transmission systems and components (1)

- Vehicles - mechanical components and parts (1)