- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- test bench

Results for

Test bench - Import export

MERECS ENGINEERING GMBH

Germany

We develop and build test stands for pumps and can refer to several references in this field. In addition, we build press-off facilities and design them individually, including suitable risk assessment. Our process visualisation is suitable for customer presentations of the running pumps directly at the pump test stand. In addition, Merecs Engineering provides the connection to the IT infrastructure of our customers (ERP systems or databases). - Planning, calculations and construction - Coordination of suppliers - LabVIEW software development - NI-Real-Time & FPGA for high-speed evaluation of speed and acceleration measurement values - Vibration analysis via FFT (updated live) - LabVIEW, NI-cRIO and Siemens S7-1500 PLC in combination possible - Database connection - On-site assembly and IB

Request for a quote

MERECS ENGINEERING GMBH

Germany

Merecs develops individual test systems for heat pumps, gas, fluid and water systems. Our engineers & fitters for electronics, installation technology and mechanics build the systems completely from one source at our location in Steinfurt. The systems are then delivered and commissioned at home and abroad. Our range of products includes - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design

Request for a quote

MERECS ENGINEERING GMBH

Germany

We are experienced in test system development for leakage testing, life time testing and end-of-line test stands in the field of gas & hydrogen technology. We also have a network of suppliers and partners who provide key components for leakage measurement, piping, sealing and instrumentation. As a general contractor and integrator, Merecs Engineering can individually design, assemble and commission the test system at our customers' sites.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

The Poppe + Potthoff impulse test stands test the operating or fatigue strength of various metal and plastic components. The endurance test in our high-pressure test systems simulates the life-cycle under varying loads. The failure tests thus show the potential weaknesses of the components with respect to design and material. The pressure is optionally modulated as a sine wave, trapezoid curve or needle pulse. Our test stands are characterized by a special ergonomics and are designed by Poppe + Potthoff machine design. Due to our flexible modular design, our machines are very variable, so that the pressure and volume range is designed according to the customer’s requirements. Of course, our systems are UL or CE compliant as required. In addition, we offer you service and support directly on-site.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

In order to prove the quality of the fluid-carrying parts, all hoses, pipes, pressure vessels and other components are put under pressure until they burst. The process is precisely measured and documented in order to optimally design the components for specific applications.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Is testing of large industrial hose or long hydraulic hose possible in a safe and practical manner? Our new P 350 test bench unifies our years of experience with your advanced requirements for special hose equipment. The extra-large test chamber gives you the space you need for your challenge. Pallets with hoses as well as large, heavy hose coils can be easily supplied to the chamber by forklift. Hose samples are connected easily with adapter hose and quick connection to pressure ports. The P 350 comes with a number of standard features such as internal lighting and a portable power aggregate, and caters to individual test logging.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Hose lines that cannot withstand the high pressure for which they are designed can cause serious damage, resulting in high costs - often higher than the price of a test bench. Why take a risk that can be easily avoided? By testing the quality of your products, you opt for safety. The P 160 workshop test bench allows for the efficient and safe final inspection and testing of hose lines. It is easy to operate and quickly become part of your routine procedures. Quality and safety •Fully enclosed test chamber •Also suitable for the static pressure testing of various hydraulic components such as valves, hydraulic cylinders, housings, quick-release couplings, etc. •Safety valve - when the hood is opened, all pressure is automatically released within 1/10 second •Hood with gas springs and transparent Makrolon® safety pane •Environmentally friendly test medium (water-oil emulsion) •Easy and safe to operate •Compressed air filter with condenser

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The P 250 Test Bench with Control C.2 IPC is a new modular test bench that can be adapted to your needs. It offers the possibility to test with Steck-o, Hand or Hydraulic quick cone system. You can also install a Euro Pallet inside. The Chamber also accepts a non-end extension if you prefer to test a hose lengthwise. The controller offers all parameters for a fully automatic test, with visualization of the pressure and may other features but also connectivity to your server or other machine in line with industry 4.0. Quality and safety •Fully enclosed test chamber •Also suitable for static pressure testing of various hydraulic components such as valves, hydraulic cylinders, housings, quickrelease couplings, etc. •Safety switch - when the hood is opened, all pressure is automatically released within 1/10 second •Environmentally friendly test medium (water-oil emulsion) •Easy and safe to operate •Quick changeover between automated and manual setup mode

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Testing has never been easier and quicker. With the P300, you can perform precision tests of hoses of up to 2500 mm in length and with pressures up to 1000 bar. Test up to 120 hoses per hour, making use of 4 parallel test lines and our quick-clamping system. You can choose between automated and manual setup mode. The P300 comes with a number of standard features such as an internal lighting and a portable power aggregate, and caters for individual test logging. •Testing of up to 120 hoses per hour •4 parallel test specimen •Combination of two test chambers (mirror arrangement) •Fast workflow thanks to separately running test chambers (for alternate setup and testing) •Quick-clamping system holding up to 4 hoses for parallel testing with customised settings •Internal lighting system, adjustable machine feet and top-quality internal gear pump •Quick changeover between automated and manual setup mode •Separate portable power aggregate (with 2m connecting cable)

Request for a quote

SAR GRÖPLER GMBH

Germany

Dokumentation in der Datenbank

Request for a quote

KREBS & AULICH GMBH

Germany

permanent magnetic test bench motors for power train and component test applications

Request for a quote

KREBS & AULICH GMBH

Germany

permanent magnetic test bench motors for power train and component test applications

Request for a quote

KREBS & AULICH GMBH

Germany

permanent magnetic test bench motors for power train and component test applications

Request for a quote

MERECS ENGINEERING GMBH

Germany

We plan, build and deliver turnkey test systems for electronic and mechanical components. For example, these are test benches for quality assurance, validation and production departments of companies in various industries. Our services include e.g.: - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design - Risk assessment and CE - Commissioning, service, maintenance at home and abroad

Request for a quote

MERECS ENGINEERING GMBH

Germany

We design and manufacture individual test systems for the pressure testing of valves and pumps. Merecs Engineering has a competent network of partners for this purpose. Within this framework, we carry out the risk assessment, design, manufacturing, installation and commissioning. In addition, we connect the systems to the individual IT infrastructures (databases, ERP systems, MS PowerBI) of our customers.

Request for a quote

MERECS ENGINEERING GMBH

Germany

EOL test stand for e-charging columns and their power electronics for the simulation of different electrical loads and mains fluctuations. The test stand has automatic contacting and achieves high test throughputs in end-of-line operation. Different variants of the power electronics of electric charging columns can be tested. On the software side, Merecs Engineering relies on NI-LabVIEW and NI-TestStand.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MERECS ENGINEERING GMBH

Germany

Development and construction of test systems for environmental simulation, i.e. climate and temperature tests as well as corrosion tests (e.g. MEMS testing and automotive durability tests on tilt sensors, inclination sensors, inertial sensors, inclination sensors, automotive parts and many more). - Adjustable humidity - Typical temperature ranges are -72 to + 120°C - Parallel testing and calibration of more than 100 DUTs simultaneously per test run - Various interfaces to the DUTs can be switched like CAN, LIN, Flexray etc. - Database connection and automated data analysis using Microsoft PowerBi can be added.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

In order to ensure that castings, valves, pumps, hoses and other components or groups have been manufactured free of leakage, they are tested in non-destructive leakage tests. Oxygen, air, nitrogen or sulfur hexafluoride (SF6) can be used as the test medium.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We develop fully automatic test systems for inclination sensors and inertial sensors (MEMS, tilt sensors) according to customer requirements. With these systems, combined temperature and motion simulation is possible. We set quality standards with rate tables from Acutronic, for example. With the help of multi-axis rate tables, we can precisely position DUTs in end-of-line (EoL) test operations or for development purposes and calibrate and test them under temperatures of e.g. -40°C and up to 120°C. Merecs Engineering can also connect the test system to our customer's IT infrastructure, set up databases and automatic data analysis using Mircosoft PowerBI, so that important key figures such as First Pass Yield (FPY), process capability, system availability, statistics and trends are continuously updated and displayed on online dashboards. For example, more than 100 DUTs are possible per test run.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

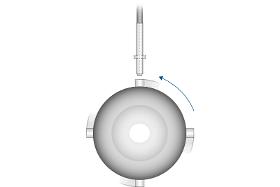

Torsionally rigid HighSpeed-couplings for test benches FlexDur FD-HS •Torsionally rigid and backlash-free torque transmission •Directly adaptable to HBM torque transducers •Suited for very high rotational speeds •Compensates for axial, radial and angular misalignments •Low reaction forces in case of shaft misalignment •Low mass moments of inertia through high power density •For use at ambient temperatures from 35 °C up to +110 °C •No maintenance or lubrication required •Almost unlimited lifetime and wear-free with proper shaft alignment

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

TOK Coupling System * Elements available in different torsional stiffnesses * Suited for highest speeds * Adaptation to DIN or SAE flanges or according to specification * Self-centering, backlash-free and maintenance-free * Optional reduction of the torsional stiffness through the use of two elements * Compensation of axial, radial and angular misalignments * Light-weight construction through the use of high-strength aluminium * Variable mounting lengths through telescopic intermediate shafts, freely pluggable * For use up to TKN depending on the application

Request for a quote

CIC - KLAUS CZERWONKA

Germany

control panels, control cabinets, pneumatic systems, pneumatic systems, control units, pre-assembled pneumatic modules for machines and plants in automation technology factory automation assembly lines test benches Also for automotive applications such as brake test benches, assembly robots, conveyor belts. Design, layout, assembly, plug and play delivery. We are also happy to use components according to the parts list, specifications or customer specifications.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Test bench couplings are applied in miscellaneous test benches. By reason of manifold, specific requirements TOK system is designed according to the modular design concept, to be applicable on almost every engine test bench. For specific requirements, e.g. special-test benches, the standard parts can be combined with specific-designed parts to derive solutions corresponding to individual conditions. Advantages of the TOK-ZW coupling system: Lowest possible torsional stiffness utilizing two flexible elements Simple adjustment of the torsional stiffness by changing of elements Compensation of axial-, radial- and angular misalignment Self-centering, backlash-free and maintenance-free Flanges adapted to DIN or SPICER bolt patterns, respectively on demand Variable installation lengths utilizing telescopic spacer shafts Ideal for highest speed Lowest possible weight by using high-tensile aluminium and CFRP We are glad to see that you are interested in our product line and are happy...

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques. An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

With the dual chamber PPM leak test stand, Poppe + Potthoff Maschinenbau offers a powerful system for testing sensors in medical device industry. The test stand can be implemented in R&D processes, but also during production as an end of line test. With pressures of up to 50 bars this equipment offers a large spectrum of testing opportunities in the medical area. Some Global Test Standards include: ISO 14644 ASTM G122-96 ASTM D6361 SAE AMS 0302 The PPM leak test stand is able to be programed to the customers requirement. The powerful in house built software enables exact design of pressure curves, such as holding times and exact pressure increase over time. It is an ideal solution for any sorts of plastic components. This exemplarily displayed test bench can utilize air or nitrogen as a test medium. Please get in touch about any other test mediums. In addition the PPM test benches can perform tests of multiple test units at a time.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures. Typical application fields are displacement and extension measurements on: —Machines —Servo systems —Motor vehicles —Test benches —Production plants The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

Request for a quote

MICRO-EPSILON

Germany

The capaNCDT CST6110 is a capacitive rotation speed sensor system for counting tasks and rotational speed measurements of any type. The industrial measuring system consists of a dust proof, water tight controller and a compact sensors which can be integrated in confined spaces. The rotation speed sensor is used in centrifugal test benches, balancing machines, generators and engines, as well as shafts and drives. The CST6110 detects and counts blades, gearwheels and nubs with the highest precision and stability even in dusty, oily environments.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Pump Set B2 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources. * Replaceable, powerful battery with Li-Ion * Battery life 35 min at maximum speed * 1 battery charge emptied approx. 12 x 200 litre container Features & Advantages * BLDC Motor with high efficiency of up to 70% * continuously adjustable * long battery life * automatic shutdown on overload * sophisticated quick lock * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C .

Request for a quoteResults for

Test bench - Import exportNumber of results

80 ProductsCountries

Company type

Category

- Measurement and control instruments (18)

- Pumps (17)

- Testing equipment (8)

- Sensors (6)

- Inner tubes (4)

- Hot-air generators (3)

- Clutches (2)

- Measurement and regulation equipment and instruments - electricity and other energy (2)

- Leak detectors (1)

- Centrifugal pumps (1)

- Ceramic, components - electric (1)

- Gas detectors (1)

- Laser - cutting and welding machines (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Monitoring and control equipment (1)

- Non-destructive tests (1)

- Valves for industrial fittings (1)

- Vehicles - mechanical components and parts (1)