- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- test and inspection

Results for

Test and inspection - Import export

TEPROSA GMBH

Germany

Testing services from a specialist: we are specialized as a testing laboratory for the simulation of specific environmental conditions and the monitoring of the influences of these conditions on electronic assemblies. We offer the following services in our test lab and at your site as contract testing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

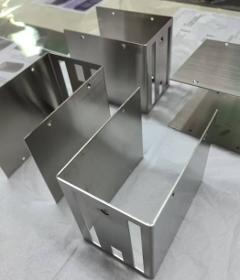

The process of sheet metal processing: Select the appropriate sheet metal, and carry out the necessary treatment and preparation, such as cutting, bending, stamping, etc Processing stage: forming the metal sheet, including cutting, bending, stamping, welding and other process operations Inspection stage: Conduct comprehensive quality inspection and evaluation of the final product, including appearance inspection, size inspection, performance testing, etc

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Automatic inspection and test unit: Automatic choice of measuring ranges from 200 μΩ to 20 kΩ Resolution up to 1 nΩ Standard interfaces IEEE488, RS232, RS485, (USB and Ethernet option) Checking of tolerances, classifi cation with statistics Highest measuring accuracy: Measuring error ≤ 0.01 % Future-orientated measuring method with thermal e.m.f. compensation. High level of stability due to constant comparisons with internal reference values. Inductive probes: Current regulation results in voltage-free disconnection, calculation of cooling curves of coils. Menu control: Setting for measuring current entry for absolute or relative limits, classifi cation with statistics, bar display for calibration of measuring probes, determination of resistivity, and many other functions. The operation of the measuring section of the RESISTOMAT® model 2304, 2305 high-precision inspection and test unit is based on an upgraded 4-wire design.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

The D-Tect X-ray inspection software is completely developed by DÜRR NDT and is the perfect complement to all digital X-ray systems like imaging plate scanners and flat panel detectors (DDAs). DICONDE compliant The user can be certain that images can be viewed on any other DICONDE compliant system. All-in-one All functions are included: from image acquisition, image evaluation and report generation to data import and export. High performance GPU and multi-core CPU support makes D-Tect X extremely fast and efficient.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Hose lines that cannot withstand the high pressure for which they are designed can cause serious damage, resulting in high costs - often higher than the price of a test bench. Why take a risk that can be easily avoided? By testing the quality of your products, you opt for safety. The P 160 workshop test bench allows for the efficient and safe final inspection and testing of hose lines. It is easy to operate and quickly become part of your routine procedures. Quality and safety •Fully enclosed test chamber •Also suitable for the static pressure testing of various hydraulic components such as valves, hydraulic cylinders, housings, quick-release couplings, etc. •Safety valve - when the hood is opened, all pressure is automatically released within 1/10 second •Hood with gas springs and transparent Makrolon® safety pane •Environmentally friendly test medium (water-oil emulsion) •Easy and safe to operate •Compressed air filter with condenser

Request for a quote

RUHLAMAT GMBH

Germany

Test systems and inspection systems form an integral part of most of the automated solutions we employ. Each assembly process is usually followed by an inspection process so that the highest quality requirements can be satisfied. Both laboratory as well as stand alone or inline series inspection systems (EOL) have already been widely implemented by ruhlamat. Inspection results (product/process data) are documented in individual or customer-specific databases (traceability). Seamless traceability of product and process data Inline process control and monitoring Efficiency through timely trend control 100% inspection

Request for a quote

RUHLAMAT GMBH

Germany

Encapsulation is the method for protecting the chip and wires against mechanical stress and environmental influences. For this purpose, cast resin is dispensed and then cured by UV light or heat, depending on the type of resin. The PowerSeal offers highest quality and maximum speed for the encapsulation of chip modules with up to 40,000 modules/hour. PowerTest - Chip Module Test System The inspection of IC modules for smart cards and RFID devices, based on parametric and functional testing, is an integral part in the production flow and quality assurance. The PowerTest is designed for high-speed testing and encoding of chip modules on 35 mm tapes. The system is also perfectly suited for initialisation and personalisation of IC modules, including OS loading. GTL700 - Glue Tape Lamination System The GTL700 is a highly reliable and flexible system for glue tape lamination of chip module tapes in preparation for the hot melt implanting process. The very efficient system can...

Request for a quote

TOPTICA PHOTONICS AG

Germany

TOPTICA's high-power single-frequency diode lasers are ideal coherent laser sources for a multitude of demanding applications, including lithography, optics test & inspection and holography. These lasers pave the way to manufacture high-quality optics for Augmented Reality (AR), Virtual Reality (VR) or Mixed Reality (MR). For example, ultra-precise optical gratings are easily produced with these laser systems to fabricate hologram projections or holographic safety features.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Vibrating tables suitable for testing and quality inspection of sensitive components The vibratingsystems are employed for simulation of stress created by mechanic vibrations on mechanical and electrical components and subassemblies with the following features: Direction of oscillation: linear - horizontal (sinusoidal oscillation), adjustable by means of a selector. Either oscillation in x-axis or alternatively in y-axis

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - autonomous driving - electromobility - connected car - electric pumps - operating elements - door locks - instruments - airbag inflators and igniters - gearboxes Development of part-feeding systems and test systems. Assembly and inspections lines that we've already developed: - Airbag inflators - Intercoolers - Oil pumps - Door and trunk locks - Instrument components - Vehicle components for driver assistance systems - Step motors and servo motors - Quick-release clutch systems - Gearbox balance shafts (for checking run-out accuracy and backlash) Assembly lines we have been involved in: - Lighting components (H7 / Xenon / LED) - Safety belt height adjuster - Heatable windscreen washer jets Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

- Quality control and safeguarding - Individual test values and criteria - Customer-specific measuring and testing plants - Single measuring systems with manual assembly - Fully integrated and automated testing plants using robots - Optical, acoustic or electrical systems with/ without parts contact, data preparation, analysis Measuring and testing systems we were involved in: - Camera systems with corresponding image processing - Part recognition, positioning, color and surface examination, checking for damages - Optical / tactile / ultrasonic tests using sensors and displacement measurement systems - Leakage and pressure tests - Inspection and monitoring of filling level - Run-out properties and accuracy - Backlash measurement - Electrical tests and measurements - Electrical values, check measurements, switching and opening properties Used in all branches: e.g. pharmaceuticals industry, medical engineering, cosmetics, electronics and automotive industries.

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

TEST GMBH

Germany

Traceable calibration of testing machines and instruments is essential for industrial quality control. Calibration certificates are a compelling proof of test equipment inspection for the standards DIN EN ISO 9000ff and DIN EN ISO / IEC 17025. The time intervals for the calibration will depend on the applicable standard, but should normally not exceed 12 months. Attention should also be paid to the rules for local changes or repairs. Take advantage of our many years of experience in the field of calibration. TesT is accredited by the German Calibration Service (DAkkS, member of WECC) for on-site calibration of testing machines, for the quantities force, length and torque as well as a permanent laboratory for calibration of compressive force transducers

Request for a quote

SIM AUTOMATION GMBH

Germany

Small parts in large quantities? Electrical engineering in particular requires very quick machines. Electrical engineering is also becoming increasingly important in IT, with particularly small components required here. The machines from SIM Automation GmbH can detect even the smallest deviations of mere millimeters during sorting. We have produced assembly and testing lines for the following components in electrical engineering (extract): - Instrument components - Step motors and servo motors - Quick-release clutch systems - Gearbox balance shafts (for checking run-out accuracy and backlash) Assembly lines: - Plug contacts (vehicle electrical systems) - Industrial sockets and switches - Sockets / light switches - Electric heater control valves - Electric razors - Electric toothbrushes Testing and inspection: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - IV catheters - dialyzers - drip chambers - lab-on-a-chip systems, used for various diagnostic analyses and processes in the laboratory on a single chip Assembly and inspection plants in medical engineering that we have been involved in: - Fiber and panel membrane filters - Syringe and infusion systems - Tablet storage and packaging - Flacons / Flacon caps - Lipstick and mascara containers - Coronary testers / rapid blood tests - Sterile caps / membrane seal systems - Components for inhalers - Surgical disposable razors Testing and inspection lines for: - Pacemakers - Dialysis filters Hygienic design is also important here. Back in 2008, we established a clean room in line with Class C / ISO Class 7 requirements in our manufacturing facilities specially for this application area.

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM feeding and sorting systems ensure the reliability of our assembly, testing and inspection systems. We develop, design, manufacture and adapt these systems based on customer specifications and the existing assembly system. A combination of various feeding, handling, camera and sensor systems, robots can be used in additional to individual systems. The systems are used in virtually all industrial branches, including medical engineering, pharmaceuticals, food and cosmetics, the automotive industry and electrical engineering. Feeding systems are an important part of automation technology, as are the isolation and provision of individual components. In addition to simple feeding systems, complex testing, measuring and assembly processes can be added without any problems. Different feeding systems can also be combined thanks to the use of robots and handling systems. In this way, we create a seamless transition from simple part feeding through to compact feeding and testing cells.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Inspection and testing devices from HEIDENHAIN HEIDENHAIN encoders provide all of the information needed for commissioning, monitoring, and diagnostics. For the analysis of these encoders, HEIDENHAIN offers the appropriate PWM inspection devices and PWT testing units. The PWM inspection devices, which are universally deployable, feature calibration capability and low measuring tolerances. Testing devices such as the PWT 101 provide fewer functions, have wider tolerances, and cannot be calibrated

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

Optical inspection with the new stand-alone camera system allows for inexpensive and flexible testing of several production processes. Inspection with the high definition system camera (18/42 megapixels) is controlled and analyzed by a Microsoft Windows-based computer running the professional modus AOI-software. Characteristics Single system for the inspection of objects within an offline application (One Piece Flow). Combination of various inspection tasks such as SMD-THT-UV, bond inspection as well as laser solder inspection. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quoteResults for

Test and inspection - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Automation - systems and equipment (3)

- Laser - cutting and welding machines (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Electrical components and parts (1)

- Goods handling systems, continuous (1)

- Inner tubes (1)

- Measurement - Equipment & Instruments (1)

- Measurement and control instruments (1)

- Monitors, computer (1)

- Non-destructive tests (1)

- Sheet metal and strips, tinplate (1)

- Supply vessels (1)

- Testing of products and materials (1)