- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- systems for liquids

Results for

Systems for liquids - Import export

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ Valve sizes from DN 15 - DN 50 ■ up to 16 mixtures fully automatically in unattended night-time operation ■ Scale size: 1500 kg; 20 g indicated scale resolution ■ Dosing accuracy +/- 20 g ■ Parallel dosing on several scales ■ Barcode-supported dosing ■ quick adaptation to dosing containers between 150 l and 1500 l ■ customised container transport systems ■ integrated, environmentally friendly extraction at the current dosing point ■ optional: Pipeline planning and design ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ Valve sizes from DN 15 - DN 50 ■ up to 16 mixtures fully automatically in unattended night-time operation ■ Scale size: 1500 kg; 20 g indicated scale resolution ■ Dosing accuracy +/- 20 g ■ Parallel dosing on several scales ■ Barcode-supported dosing ■ quick adaptation to dosing containers between 150 l and 1500 l ■ customised container transport systems ■ integrated, environmentally friendly extraction at the current dosing point ■ optional: Pipeline planning and design ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ up to 16 fully automatic mixing recipes during the unattended night shift ■ scale sizes: 300/600 kgs; 1 g / 2 g indicated scale resolution ■ dosing accuracy: +/- 5 g / +/- 6 g ■ parallel dosing on several scales ■ valve sizes from DN 15 to DN 50 ■ fast adaptation to dosing containers between 75 litres and 600 litres ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound extraction system directly at the dosing point ■ Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 mixes automatically in night mode ■ 2000 doses per day ■ Liquid dosing up to 25 kg batch size ■ Scales with 30 kg or 60 kg capacity and 10 mg or 20 mg indicated scale resolution ■ 50 mg or 60 mg dosing accuracy ■ DN 8 valves ■ Parallel dosing for high speed ■ Barcode-supported dosing ■ Customisable system sizes and container transport systems ■ Integrated environmentally friendly extraction system ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing system for laboratory and small scale production mixes up to 6 kg batch size Space-saving this system combines all advantages of a laboratory dosing system to the production capacity of the larger systems Concordia II – V (C 2 – 5). ■ batch sizes up to 6 kg ■ more than 130 fully automatic mixing recipes during the unattended night shift ■ 7000 dosing cycles per day ■ dosing precision on the 6 kg scale: +/- 5 mg ■ smallest dosable quantity on the 6 kg scale: 20 mg ■ modular design for up to 1000 components ■ barcode assisted dosing ■ high dosing speed through parallel dosing on several scales ■ individual container transport Systems ■ various raw material storage Systems ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Creative and sampling laboratories are familiar with the problem: cramped premises with no alternatives, hardly any space for the extensive ingredients and tight deadlines. Specially developed for office buildings, the modular and space-saving laboratory systems can automate up to 600 components with maximum precision. From now on, fast presentations of mixtures will be a further advantage for your company. ■ 34 mixtures fully automatically in unattended night-time operation ■ Optionally up to 54 mixes ■ 2,000 doses per day ■ Barcode-supported dosing ■ Dosing accuracy with 6 kg scale: ±3 mg ■ Smallest dosing quantity with 6 kg scale: 5 mg ■ Mixtures up to 1 000 ml ■ Quick presentation of dosing results ■ cooled and heated components ■ Modular design for different sizes (100-500 components) ■ Integrated storage system

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Since the foundation of IFA Technology GmbH, we have been active in the paper industry. Our systems for liquid dosing and solids dosing systems are used in paper production or water treatment and enable you to optimise your processes. With our dosing systems for paper finishing we offer a wide repertoire for the production of paints and impregnating resins. Application of plants and systems for the paper industry: Storage, mixing and dosing of liquids such as impregnating resins, adhesives and release agents Solids dosing with the aid of preparation stations Dosing systems for printing inks

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised plants and systems for the paint industry and the varnish industry. Our plants and systems for dosing liquids and solids in the paint and varnish industry offer high dosing accuracy and perfect reproducibility. We meet the high demands of our customers through the use of high-quality materials and precise workmanship. Application of plants and systems for the paint industry and the varnish industry: Storage, mixing, dosing and application of paints and varnishes Special dosing valves and dosing pumps for paints and varnishes

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WIDE RANGE OF TANK ACCESSORIES FOR TECHNICAL EQUIPMENT Whether grain silos, biogas systems or liquid manure containers, Lipp places the greatest importance on quality, safety, a long service life and cost efficiency over its entire product portfolio – including accessories. The whole is more than the sum of its parts. That is especially true for Lipp container solutions and systems as special attention is paid to all parts – including tank accessories – to ensure quality, safety, longevity and cost efficiency. A broad range of technical tank accessories is available for all containers. Some are produced in house and some are purchased via partners or carefully selected suppliers with whom Lipp has established long term relationships based on trust. ACCESSORIES Container bottoms Container insulation Pumping and stirring technology Overflow gutters Container heating Steps, platforms and operating bridges Overpressure and underpressure protection devices Pipeline construction

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

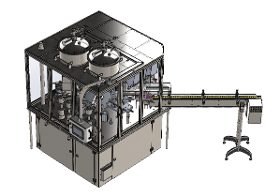

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

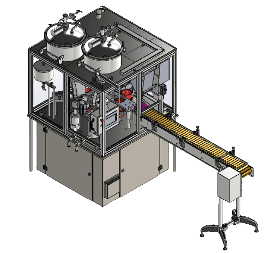

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

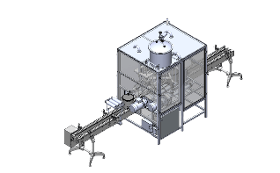

Challenger 506D is fully automatic mechanical linear system It’s designed for filling liquid or pasty products in plastic bucket With five work stations: Adding buckets, filling, adding covers, pressing cover, Exiting

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

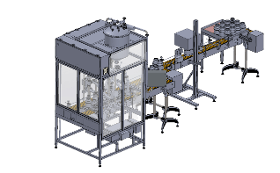

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers the complete range of conveying systems, storage systems and handling systems in mechanical engineering. Our plants and systems can be integrated into your own conveyor line or designed as completely automated systems. External plant components can also be integrated into our superordinate control system. Our plants and systems are mainly used for bagging or bottling or batch loading systems. Application of conveying, storage and handling systems: Dosing and application of liquids in the plant process Dosing and mixing of powders, fibres and liquids Bagging and bottling systems integrated into a production line Silo systems and tank systems with conveying paths and mixing systems Pipe shell plants

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers tailor-made plants and systems for the animal feed industry. Our mixing and dosing systems process both liquid and solid components, which are used for the production of animal feed, mineral feed and supplementary feed. To supplement our plant systems, we also offer adapted silo systems and tank systems as well as multifunctional filling systems and bagging or bottling systems for all types of containers. Our animal feed plants and systems are made of high-quality stainless steel and use food-grade materials and FDA-approved (Food and Drug Administration) components. Our focus is on hygiene and the diligence of the respective plant processes. The latest plant technologies guarantee the required degree of accuracy, economy and process reliability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IFA TECHNOLOGY GMBH

Germany

Gravimetric dosing or weight-controlled dosing is based on the principle of weighing technology. The weight of the weighed material is measured via load cells or weighing cells either directly or by loss-in-weight. IFA Technology offers you specific solutions tailored to your individual needs for weighing, mixing and dosing solids or liquids. We consider your individual requirements and build customised dosing systems for you. The system "IFA-Gravimet" is our standard system in the field of gravimetric dosing. We supply a complete, ready-to-operate pre-assembled weighing, mixing and dosing system. As a complete system for weighing, mixing and dosing liquids, the system can be individually customised to suit your requirements.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANKS AND SYSTEM SOLUTIONS FOR SOLID, LIQUID AND GASEOUS SUBSTANCES As a tank construction specialist, we offer quality tanks and system solutions in steel for industry, communities and agriculture. Our unique Lipp System construction method ensures the highest levels of quality when storing solid, liquid and gaseous substances. Your project, from an individual tank to a complete turnkey plant, will be completed with the emphasis firmly on longevity, flexibility and individual adaptability. With over 55 years experience in plant and tank construction, LIPP GmbH is a family company which is active worldwide. We have carried out over 10,000 projects world wide and own over 170 pioneering patents.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B2 Battery Trolley is the ideal companion when it comes to mobile chemical refuelling The safe transport ensures that even small quantities are not spilled. The Drum Pumps B1 & B2 Battery stand for long battery life, low weight and low noise. The integrated ventilation system enables continuous removal of the liquids. Large wheels facilitate handling on stairs and off-road. * Outside dimensions in cm: 100 x 59 x 43 * Capacity up to 100 litres * Suitable for cleaning agents and chemicals

Request for a quote

PRESSTA EISELE GMBH

Germany

A double head mitre saw with disappearing blades specifically studied for the tubular steel shapes. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 45° and 135°. It is equipped with the system TS 690. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Speed of rotation of the blades, variable by means of a frequency converter (inverter). Automatic shifting of the support plates of the profile once over the cutting cycle. Dynamic protection guards for a total covering of the cutting area. Blade lubrication cooling system with electric pump. Coolant liquid vat with extractable pump for vat cleaning. Cutting deepth stop device. Intermediate workpiece support automatically operating Mobile roller conveyor with pneumatic clamp for section support Compressed air treatment unit (filter/reducer/lubricator)

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

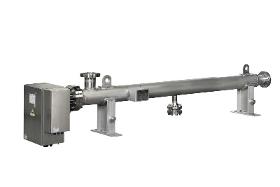

CSN® explosionproof flow heaters are used for heating up flowing gases and liquids in hazardous areas. The devices consist of explosionproof flanged immersion heaters, which are installed in corresponding pipe or pressure vessel. Our products realize individual solutions for complicated technical process. Different heating systems for heating up liquids, nitrogen or other gases activate exact determinded processes in chemical factories. In close discussion with our customers problems will be defined and changed in technical optimale solutions. Our QualityManagementSystem ensures the high quality level of our customers. Further information about our CSN® Exflow heater

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The Dosing Star is characterised by its very high dosing accuracy at maximum dosing speed. The design is modular. Each module has its own scale. In addition to the variable number of dosing modules with the valve containers, the Dosing Star has a linear gantry for distributing the batch containers to the individual modules. Up to 25 mixing containers are each placed on a tray trolley. Four trolleys can now be conveniently pushed into the system. Thanks to the modular design of the dosing system, it is possible to connect up to 8 dosing modules to the linear gantry. A maximum of 128 valve containers can be stored in each of the dosing modules. ■ Fast dosing in containers with an opening diameter from approx. 15 mm ■ Gripping system for time-optimised distribution of the mixing containers to up to 8 dosing modules ■ Fixed and flexible barcodes can be used ■ Rush orders are optimally integrated into the production process

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quoteResults for

Systems for liquids - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Weighing and dosing equipment (10)

- Oiling - machines and systems (8)

- Bottling and filling - machinery and equipment (7)

- Goods handling systems, continuous (6)

- Automation - systems and equipment (4)

- Filters, liquid (4)

- Tanks, metal (2)

- Dosing - machines and equipment (1)

- Fastening devices - machines for production (1)

- Generating units (1)

- Induction heating systems (1)

- Mechanical engineering - custom work (1)

- Pumps (1)

- Water extraction - systems and equipment (1)