- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steels and metals - forming and cutting

Results for

Steels and metals - forming and cutting - Import export

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

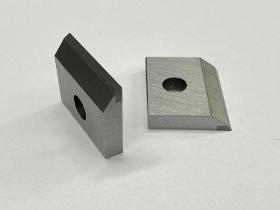

Different tungsten carbide qualities with a hardness above those of the standard and PM special qualities. Through clean grinding materials, we achieve a long working life through high resistance to wear.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Only the best for our forests Nowadays, forestry bears responsibility for numerous important tasks and is increasing not only in its commercial, but also in its environmental and social significance. In addition to continuous production of renewable raw materials (mainly wood) it is assuming the task of forest conservation, not least as a protected and recreational space for mankind and the animal kingdom. The predominantly municipal forestry operations are directed for the performance of these tasks at mobile woodcutters and robust wood chipping machines. We have supported the forestry industry for many years with our longlasting choppers and counterknives, as well as with shredder knives.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Rotary shear knives made from tool and PM steels in the highest OEM quality with a hardness of up to 60 HRc. CNCcontrolled machines guarantee you tight and consistent form and position tolerance for the knives. Inquire now.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

State of the art machines, tightest tolerances Machine knives for use in steel production are challenging from a production engineering point of view and place enormous demands on quality. A knife change always entails a long and thus costly system shutdown; consequently, long knives and circular knives from our company are characterised not only by very high accuracy, but also by their extreme resistance to wear. In the past, we have made serious investments in our machine fleet, in order also to produce to the most complicated geometries and tightest tolerances. In addition to standard qualities, we also deliver special qualities for particular stress at high temperatures.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

So that it continues The less than ideal condition of the roads in Europe, as well as the need to catch up in road construction in the Asian world has led to high investments in the construction industry. We have already specialised for many years in the manufacture of compacting bars and pressing bars for road builders. Whether casehardened or inductively hardened bars From us, you will always find a product matched ideally to your requirements.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

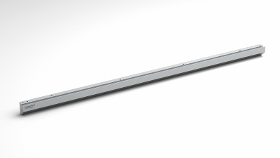

This how each cut is made Sheet metal is available in a very wide range of materials and alloys. The criterion for machining is a given toughness and strength to make the metal sheets deformable. A part of sheet metal machining is separation by shearing, in which the sheets are divided by two shearing knives. For over 40 years, we have supplied shearing knives in lengths up to 4,190 mm in qualities and hardnesses specially matched to the purpose for the corresponding machines. By using peripheral grinding machines, we can comply with the tightest form and position tolerances, which is why so many machine manufacturers rely on the quality of our shearing knives.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Robust and durable As a naturally renewable raw material, wood is not only one of our favourite building materials, it can also be disposed of and recycled with comparative ease. For old wood recycling, tables, kitchens, damaged railway sleepers or chipboard are recycled using singleshaft shredders. In these machines, our cutting crowns and knife holders in a very wide variety of sizes and versions have been used for many years and have proven themselves in practice day after day.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Costconscious use of resources Every year in Germany, several million refrigeratorsare disposed of . With this enormous volume, refrigerators are certainly counted among the most important recycling products. After removing the chlorofluorocarbons, in a second step the housings are broken down into their individual components – iron, aluminium, copper and plastics. These are then made available again to industry as secondary raw materials. We equip our clients with extremely tough and hardwearing shredder disks and thus contribute to costconscious handling of resources.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Recycling made easy Our machine knives, of uncompromising quality, have been used for decades in recycling for tyre crushing. Even when separating rubber and spring steel, they have been proven in practice day by day. Whether shredder knives, spacers, scrapers or sealing gaskets, shredder teeth for multipleshaft shredders, rotary and stator knives for granulators or machine knives for guillotines Our complete range of products also covers the most demanding challenges in recycling.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Optimum crushing instead of cable salad The very best method for crushing of cables or electrical scrap has brought many a tool to its limits and yet this is a frequently underestimated source of money. In addition to expensive copper, the recycling process also recovers aluminium and noble metals. In order to reach these valuable raw materials, robust preliminary crushing units are used, followed by a second crushing cycle. The demands on the crushing knives cannot be ignored and they must therefore be very tough. We are at the side of our partners to give advice on the selection of ideal materials and the best heat treatment.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Clothing instead of landfill PET must beone of the most interesting recycling materials of recent years as, during this time, not only new bottles, but also clothing and much more have been produced from recycled bottles. In Germany alone, each year the volume of PET bottles discarded when empty has exceeded 400,000 [tonnes], 96% of which is taken to professional recycling. An additional 60,000 tonnes arises annually as packaging material. However, PET is an extremely abrasive material, which exacts enormous demands on the tools used in recycling. Our knives have been proven by their high resistance to wear, and we also supply, in addition to our proven quality standards, extremely hardwearing special qualities.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Less wear, longer working lives In the automobile industry, environmental protection is also playing an ever greater role. With its dimensions, bodies form by far the largest part of recyclates in automobile recycling. One of the major challenges in crushing vehicle bodies is in the vulnerability to wear of many hammer axes. We have optimised our solutions over a number of years and supply hammer axes for large shredders in various diameters, which are characterised by extreme toughness and dimensional stability. This is how our clients profit from optimum working lives for their recycling machines.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Trimmed for peak performance The construction industry is booming – and this has been the case for decades and all across the world. The need for new buildings, bridges and general infrastructure is constantly increasing. In terms of modern urban development, the demolition of buildings that are no longer up to date is part of everyday life. The stress on the tools used for this is easy to imagine. Demolition shears are used, for example, to cut angle iron or wire mesh, or to cut concrete ribs and steel rods. Our shearing knives or shear blades for mobile demolition shears are designed exactly for these massive stresses and have been used for many years on construction sites all over the world.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Market leader with OEM quality In principle, metals can be melted on numerous occasions and reworked. This is, therefore, conventional recycling, , as a new product with similar properties and of identical quality comes from a starter material. In addition to hammer axes, the scrap shearing knives used in this industry are in our product range. Since the beginning of scrap recycling, our clients have relied on our highly accurate and extremely robust shearing knives and, even today, we are, with our 100 years of experience, a market leader in this sector. You find our Webshop https//shop.buchholzgruppe.eu/shop We also supply you the necessary machine parts (knife seat and knife holder) for the overhaul of your shear.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Market leader with OEM quality In principle, metals can be melted on numerous occasions and reworked. This is, therefore, conventional recycling, , as a new product with similar properties and of identical quality comes from a starter material. In addition to hammer axes, the scrap shearing knives used in this industry are in our product range. Since the beginning of scrap recycling, our clients have relied on our highly accurate and extremely robust shearing knives and, even today, we are, with our 100 years of experience, a market leader in this sector. You find our Webshop https//shop.buchholzgruppe.eu/shop/

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Gears are mechanical components and an essential part of many machines and are used in everything from piston engines to gearbox construction to agricultural machinery and wind turbines. Main gear types are: Spur and Pinion Gears: These gears have straight teeth and are the most common. They transmit rotational movements parallel to the axis and are found in gears, clocks and machines. Bevel Gears: These gears have tapered teeth and movement between non-parallel axes. They are used in differential gears of vehicles and in industrial machinery. Worm Gear: This combination of worm and worm wheel provides high gear ratio and is used in hoists, conveyors and other applications. Hydraulic The West German drop forge KB Schmiedetechnik GmbH produces forged gear blanks, piston parts and hydraulic components for a wide range of applications - from agricultural machinery and conveyor technology to engine construction, diesel generators to shipbuilding.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We manufacture and deliver the complete range of simple carrier roller holders, e.g. for the lower belt roll and 2 or 3 part upper belt stations in all trough angles. We are happy to manufacture and deliver simple to complex upper belt steering stations. We offer you Let us know when you inquire whether we should offer the conveyor roller stations in a primed, painted, galvanized or special version.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHMALE MASCHINENBAU GMBH

Germany

Special machines from Schmale Maschinenbau are equipped with an intelligent combination of technologies. The plant shown above is used to manufacture reinforcement items from solid material with a diameter of 20mm for the building industry. Servo-electric units such as bending slides, presses and finger benders are combined into customer-specific solutions for the production of individual items that can not be produced on standard machines. Schmale offers special machines for wire, tube and strip processing. You can watch various special machines for the production of different forming articles on our YouTube channel. https://www.youtube.com/channel/UCziuQiA3kXBVfH4ecLxQ2JA/videos

Request for a quote

CRAEMER GMBH

Germany

Craemer is a specialist for constructing and manufacturing complex metal components and a well-known international supplier for the automotive, commercial vehicle, large domestic appliance and heating industries. The sheet metal components are sold to leading car producers, such as BMW, Mercedes Benz, GM, Volkswagen and Audi. Miele and other world brands are being supplied with white goods. The Craemer Group is one of the leading European manufacturers in the high volume serial production of car-modules, particularly components for seating structure and seatbelts. We process: sheet steel, high-strength sheet steel, high-grade steel and aluminium sheet Manufacturing process: hydraulic and mechanical presses with progressive die, transfer and servo direct technology as well as modern facilities for assembly production. Press capacity of between 3,150 and 25,000 kilonewton at a maximum table-length of 8,000 millimeters

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The electronic display of the control system visualizes operations, fault tracing and indicated maintenance rates which ensure an optimum machine utilization. Storable processing programs allow repeatable results. This Kraftformer model is particularly recommended for the forming of sheet metal in the industrial metal construction sector as it is capable of machining large steel components with a sheet thickness of up to 3 mm. For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). • choice of two preselectable stroke speeds • adjustable reverse position • 4 storable processing programs • repeatable results • electronic display/fault tracing Max. forming capacity Steel 400 N/mm²: 3.0 mm Aluminium 250 N/mm²: 4.0 mm Inox 600 N/mm²: 2.0 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the Handformer HF 100. This Multiformer MF 500 GL 2 consists of: English wheeling machine MF 500 + planishing hammer GL 2 Optionally available with a Handformer HF 100 for shrinking (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD Kraftformer KF 324 - Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The cult-classic among the Eckold machines, the ECKOLD Kraftformer KF 324, is the cheapest motor-driven machine of the Kraftformer series. It is also known as ECKOLD Piccolo and has been designed for a long service life. Metal workers all over the world are delighted with this machine, as it works perfectly for many decades. With the ECKOLD Kraftformer KF 324, the press force is controlled by means of a hand wheel. This model is designed for the forming of steel sheets up to 2 mm in thickness. For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 2.0 mm Aluminium 250 N/mm²: 2.5 mm Inox 600 N/mm²: 1.5 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD Kraftformer KF 170 PD - Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming, straightening, punching, notching and clinching. The Kraftformer KF 170 PD with pneumatic drive is the most compact of all ECKOLD Kraftformers. The machine is designed for single or continuous stroke operation for forming steel sheets with a thickness of up to 2 mm. Operated in single stroke mode, the KF 170 PD is the ideal machine for reworking and adjusting tasks. It can be used for punching, notching and clinching. In continuous mode, the KF 170 PD allows for fast and easy forming. In single stroke mode, it caters for precision hole punching, clinching and reworking! For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 2.0 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.5 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2. This Multiformer MF 500 MAX consists of: English wheeling machine MF 500 + Handformer HF 100 for shrinking For our Handformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Optionally available with a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2 and/or the Handformer HF 100. This Multiformer MF 500 EW consists of: English wheeling machine MF 500 Optionally available with a Handformer HF 100 for shrinking and/or a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The ECKOLD Kraftformer KF 340 is part of the medium-force Kraftformer range with motor drive. Depending on the workpiece to be machined, the operator can adjust the number of working strokes to any value between 220 and 600 strokes per minute continuously. Low speeds are particularly suitable for shrinking, stretching and for straightening and precision finishing. Thanks to the high stroke rate, the machine is also widely used for doming (dishing) and planishing, boosting productivity. This Kraftformer is capable of machining steel sheets of up to 3 mm in thickness! For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 3.0 mm Aluminium 250 N/mm²: 4.0 mm Inox 600 N/mm²: 2.0 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

MF 800 - A complete workshop in one machine. The MF 800 MultiFormer is the ingenious multi-functional machine for stretching, planishing, driving and shrinking of metal sheets. This sophisticated wheeling machine is ideal for working on medium to large size work pieces: such as motorbike tanks, fenders, hoods, bonnets, door panels, etc. The compact machine comes fully equipped with castors so that it can be moved to any location in the workshop. • Large tool shelves • Wheels and wheel supports rotatable by 90° • Roller angle adjustable • Large selection of optional accessories • Quick tool change This Multiformer MF 800 KIT 2 consists of: English wheeling machine MF 800 and Handformer HF 100 for shrinking Optionally available with a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 3.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD Handformer HF 100 PA for stretching, shrinking, notching, hole punching, edging and clinching. When working with the HF 100 PA, you can use both hands to hold and guide your workpiece, while the precision strokes are triggered with a foot pedal. The Handformer HF 100 PA is therefore the ideal device for the forming of large, unwieldy workpieces. The machine is pneumatically driven and features a pressure control device to prevent tool overload. Each machining process is actuated by pressing the foot switch, whereby the stroke force is proportional to the force applied to the pedal. • Adjustable working height • Quick tool change • Tool storage trays • Stop for precision guidance of workpieces For our Handformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

MF 800 - A complete workshop in one machine. The MF 800 MultiFormer is the ingenious multi-functional machine for stretching, planishing, driving and shrinking of metal sheets. This sophisticated wheeling machine is ideal for working on medium to large size work pieces: such as motorbike tanks, fenders, hoods, bonnets, door panels, etc. The compact machine comes fully equipped with castors so that it can be moved to any location in the workshop. • Large tool shelves • Wheels and wheel supports rotatable by 90° • Roller angle adjustable • Large selection of optional accessories • Quick tool change This Multiformer MF 800 KIT 1 consists of: English wheeling machine MF 800 Optionally available with a Handformer HF 100 for shrinking and/or a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 3.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quoteResults for

Steels and metals - forming and cutting - Import exportNumber of results

37 ProductsCountries

Company type