- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stationary

Results for

Stationary - Import export

KAUP GMBH & CO KG

Germany

1000-fold proven components of the KAUP modular design combined in a particular way: these make up KAUP Stationary Material Handling Equipment. They consist of project related system solutions which can be integrated in every production process. Our devices have already been implemented for handling bagged products such as sugar or cement. But also in goods handling and storage of consumer goods and beverages, when turning sheet metal or paper sheets for processing on both sides, our application orientated devices are in great demand. The majority of our equipment is driven by a hydraulic power unit. They can be controlled automatically, semiautomatically or manually and so optimally adjusted to the customer requirements.

Request for a quote

GW BATTERIEN GMBH

Germany

Maximum lifecycle for demanding applications In addition to modern NiCd batteries GW Batterie GmbH also provides conventional stationary lead batteries. Not only do we supply conventional batteries, our primary focus is on providing customised battery solutions including the appropriate accessories. An overview of our stationary lead batteries: Lead Batteries Sealed, Closed Types Sealed: AGM, Gel Closed: OGI, OPZS, GroE Design 2 V, 6 V and 12 V Single cell and block batteries Capacity 0.8 Ah - 3500 Ah Application Back-up power supply units for power stations Telecommunications UPS systems Signalling systems Safety lighting

Request for a quote

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, stationary continuous mixing plants (pugmills) are mainly used for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Equipped with 5000/2500 l. capacity ELKON continuous twinshaft mixer, there two models of pugmill plants, 300 tons/h and 500 tons/h capacity. In this mixing plants, thanks to aggregate bins equipped with dosing belts, it’s possible to adjust material flow rate by means of frequency inverters. Cement flow rate can also be precisely adjusted by a screw equipped with frequency inverter whilst the water flow by a proportional valve. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quote

ELKON GMBH

Germany

ELKON stationary concrete batching plants have been manufacturing since 1980’s. ELKOMIX-240 stationary concrete batching plant from the series is equipped with 9000/6000 l. twin shaft mixer. ELKOMIX-240 Stationary Concrete Batching Plant which has 240 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology, provides following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

ELKON GMBH

Germany

ELKON stationary concrete batching plants have been manufacturing since 1980’s. ELKOMIX-200 stationary concrete batching plant from the series is equipped with 7500/5000 l. twin shaft mixer. ELKOMIX-200 Stationary Concrete Batching Plant which has 195-200 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology, provides following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

ELKON GMBH

Germany

ELKON stationary concrete batching plants are being manufactured since 1980’s. ELKOMIX-180 stationary concrete batching plant from the series is equipped with 6750/4500 l. twin shaft mixer. ELKOMIX-180 Stationary Concrete Batching Plant which has 175 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology and provides the following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

ELKON GMBH

Germany

ELKON stationary concrete batching plants are being manufactured since 1980’s. ELKOMIX-160 stationary concrete batching plant from the series is equipped with 6000/4000 l. twin shaft mixer. ELKOMIX-160 Stationary Concrete Batching Plant which has 150 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology, provides following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

ELKON GMBH

Germany

ELKON stationary concrete batching plants are being manufactured since 1980’s. ELKOMIX-135 stationary concrete batching plant from the series is equipped with 4500/3000 l. twin shaft mixer. Moreover, it can also be manufactured without mixer for dry type concrete production. ELKOMIX-135 Stationary Concrete Batching Plant which has 120-135 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology and provides the following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

ELKON GMBH

Germany

ELKON Stationary Concrete Batching Plants are being manufactured since 1980’s. ELKOMIX-120 stationary concrete batching plant from the series, depending on the application, can be equipped with 3000/2000 l. pan, planetary or twin shaft mixer. Moreover, it can also be manufactured without mixer for dry type concrete production. ELKOMIX-120 Stationary Concrete Batching Plant which has 105 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology and provides the following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

ELKON GMBH

Germany

ELKON stationary concrete batching plants are being manufactured since 1980’s. The lowest capacity one in this series is ELKOMIX-60 Stationary Concrete Batching Plant, depending on the application, can be equipped with 1500/1000 l. pan, twin shaft or planetary mixer. Moreover, it can also be manufactured without mixer for dry type concrete production. ELKOMIX-60 Stationary Concrete Batching Plant which has 60 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology and provides the following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

GW BATTERIEN GMBH

Germany

Professional installations and disassemblies on your premises The highly-qualified specialist personnel of GW Batterien GmbH would be happy to carry out assemblies, commissionings and also disassemblies – even in difficult conditions such as sites which are difficult to access. The commissioning process involves a complete functional test, a capacity test and further necessary tests. After a disassembly, we will of course dispose of the old battery in the correct manner.

Request for a quote

TROTEC GMBH

Germany

INDUSTRIAL CONDENSER DRYER DH 145 SThe ultimate industrial condensation dryer DH 145 S dehumidifies an enormous 475 liters per day This standard industrial dryer dehumidifies up to 475 litres per day and is a particularly economical solution for keeping stored goods dry and to prevent damages caused by mould as well as corrosion during industrial processes. The dryer comes equipped with an integrated hot gas automatic defrost, which guarantees efficient dry keeping without breaks for defrosting at certain intervals in which dehumidification pauses. Via the external outlet of the DH 145 S condensate can be drained across stories, because the standard condensate pump is designed for a discharge head of four metres. The DH 145 S is fitted with modularly refined electrical equipment and pipes containing water according to European standard – all manually finished and quality-controlled at Trotec in Germany.

Request for a quote

TROTEC GMBH

Germany

COMMERCIAL DEHUMIDIFIER TTK 75 ECOEasily (sup)portable investment for dehumidification and dry keeping The TTK 75 ECO, compact and robust in equal measure, is a pragmatic solution when an equally low-cost and high-quality construction dryer is required. The lightest device of the TTK-ECO series is equipped with cable holders and a retractable metal carrying handle and can so be conveniently transported to the operating site. Thanks to its efficient rotary piston compressor, the low-maintenance device can be transported and stored in any position. And since the TTK 75 ECO comes with a hardwearing steel construction, a rough construction site environment means no harm to this dehumidifier. Once arrived at the target location, the TTK 75 ECO is simply switched on and you're done. It immediately withdraws immense amounts of moisture from the room air – and thanks to the automatic hot gas defrosting even does so at low temperatures in unheated rooms.

Request for a quote

GW BATTERIEN GMBH

Germany

So that everything runs smoothly

Request for a quote

GW BATTERIEN GMBH

Germany

For battery systems which match your requirements perfectly. GW Batterien plans and designs customised, stationary battery systems for you. Here we include all standard chemical systems in our planning to be able to offer you a perfect solution, alternatively also with a frame and accessories. Upon request, we will happily plan your new battery system to be earthquake-proof. Thanks to our extensive storage facilites and fast delivery service your customised battery system will be delivered to you in a fully-assembled state as quickly as possible. We would be happy to advise you.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In addition to the typical lift platform applications, LAWECO offers individual solutions for special lifting requirements. From material lifting systems for high-rise construction to freight traffic and transportation or lorry lifting platforms, LAWECO develops solutions for everything that needs to be lifted. The following designs chosen as examples reveal what is possible when combining creative engineering with experience of a harmoniously cooperating team.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special needs We speak English.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

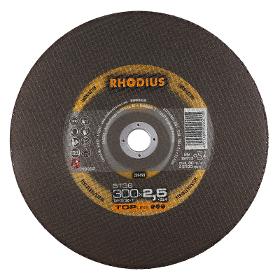

RHODIUS ABRASIVES GMBH

Germany

Stationary stainless steel disc designed specifically for chop saw use. High zircon content. Iron and sulphur free. • High cutting speed • Long service life • Easy cutting

RHODIUS ABRASIVES GMBH

Germany

Stationary cutting disc with high stock removal performance. Extra exterior reinforcement for use at high working speeds. • High cutting speed • Suitable also for cast-iron parts

RHODIUS ABRASIVES GMBH

Germany

Stationary cutting disc with high stock removal performance. Ideal for use with portable workshop machines (up to 3 kW) and chop saws. • High cutting speed • Long service life • Easy cutting

RHODIUS ABRASIVES GMBH

Germany

Heavy-duty stationary cutting disc with rugged exterior reinforcement for safe cutting. • Long lifetime • Cool cut • Easy cutting

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The HMB Honing Rigs are designed for honing cylinder liners removed from the engine block with the corresponding mobile Hunger PHM Honing Machines. - Honing Rig Type HMB 340 is tailored to the Honing Machine Type HBM 340. - Honing Rig Type HMB 640 is tailored to the Honing Machine Type HBM 640. Features Rigid base structure including upright supporting tubes for mounting the mobile PHM Honing Machine. The liner to be honed is placed on top of a honing liquid reservoir which is slideably mounted on the base structure. The reservoir can be drawn out for ease of loading and unloading of the cylinder liner by means of a crane. An electric pump is provided to supply honing liquid to a spray nozzle. The spray nozzle is mounted on a magnetic base which can be attached to the frame tube to direct the honing liquid to the area to be honed.

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

The SOMOS® RDF dryer is used for drying hygroscopic polymer pellets. It consists of compact RDF modules which can be flexibly combined, are capable of autonomous operation and have drying capacities of 10 kg/h to 250 kg/h per module. The modules are available in 7 sizes with a volume of between 30 l and 600 l and a drying are volume between 10 m3 and 180 m3, each one being individually controllable by its own controller. Alternatively, when interconnected, they can be controlled using a common operator control unit. Each module has an integrated air generator, so ruling out complete failure, as may occur with a centrally supplied drying system.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The Hunger SHM is designed for precision honing of cylinder liners with bore diameter from 150 to 640 mm. Features • Air powered honing. Powerfull air motor for rotary motion of honing head, air hoist for stroke motion and, as an unique feature, air cylinders for stone feeding. • Superior control. Manual buttons are provided for fine adjusting setting of honing head RPM, stroking rate and stone feeding pressure. • Pressure gauges for displaying the selected setting of honing head RPM, stroking rate and stone feeding pressure. • Two-hand control actuation to protect the operator according to the stringent EC safety regulations. • Automated stroking between adjustable end stops. • Drawer-type honing liquid reservoir acting as support for the cylinder liner and mounted on casters for ease of loading and unloading the cylinder liner.

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

The S 1401 is a stationary ultra fine filter system for connection to the control cabinet and for constant processing of technical oils. It runs completely independent with a motor-/pump unit. Especially on machines with continuous dirt- and water contribution it guarantees highest oil purity in the whole system. Integration into the control system of the machine enables setting of flexible processing times. These systems can also be manufactured due to individual installation measures on request. 400 V-asynchronous motor, 0.55 kW, robust construction Stable gear pump, 14 liter/minute Manometer for flow- and element control Robust design, very loadable 24/7 – unattended operation Transfer-circuit Flow regulation for high viscosity oils 1.50 m flow-/return hose Also suitable for high viscosity oils

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The HELIO®MAT dryer station is part of the JETBOXX® system and features an independent JETBOXX® dryer with full functionality at each individual docking station. The material can be predried in removable drying containers at the dryer station. The drying container can be removed and brought to the processing machine if needed. It will be attached directly onto the feeding section there and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate with dryer control are used in addition. HELIO®MAT is applicable for example as pre-drying station for quick material change, as dryer station for sampling batches, for batch drying for small quantities / sampling, for laboratory applications, or for cleanroom supply with hermetically sealed dry material containers. Material change without delay. No humidification. No cleaning issues.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

The eldec MICO-L generator offers users a particularly powerful complete solution that includes a coolant system. Medium (18 to 80 kW) and high-frequency devices (15 to 35 kW) are available. High-performance complete solution for cost-effective induction heating The L in the name of these induction heating systems stands for “large”. In the medium-frequency version, the MICO-L delivers up to 80 kW for hardening and heating parts and components. This powerhouse comes with a generator, cooling system, controller, and hose bundle. It can be moved on casters as an option (a base plate for stationary use is always included) and is therefore available at all times. Inside, carefully selected high-performance components ensure safe and precise heating processes. The reliability and efficiency of these devices is the result of decades of development and optimization by eldec.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, steel chips, shredder scrap, wood chippings and much more, in sea and inland ports and at storage facilities. For various types of handling machinery (mobile, stationary, crawler or portal) designed to be connected to hydraulic attachments. Technical design Open, half-closed or closed grip; with 2, 4 or 5 shells Optimisation of machine load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Hydraulic hoses connect the materials handling machine to the grab Closing and opening movements are controlled by the materials handling machine Closing and opening movements controlled by directly connected hydraulic cylinders Grab connection bearing Re-greaseable, robust steel bushing bearing Stable, torsion-resistant shells made of: Shell plates made of S355J2+N Welded shell tips made of special highly wear-resistant steel

Request for a quoteResults for

Stationary - Import exportNumber of results

50 ProductsCountries

- Germany (50)

- Bonn, Düsseldorf and North Rhine and Westphalia (13)

- Frankfurt am Main and Hesse (3)

- Hamburg and region (1)

- Leipzig and Saxony (4)

- Mainz and Rheinland-Pfalz (5)

- Munich, Nuremberg and Bavaria (4)

- Potsdam and Brandenburg (1)

- Schwerin and Mecklenburg-Vorpommern (8)

- Stuttgart, Freiburg and Baden-Wurtemberg (11)

Company type

Category

- Machine tools, metal machining - parts and accessories (9)

- Concrete mixers (8)

- Hydraulics systems (8)

- Construction - Machines & Equipment (2)

- De-humidifying equipment (2)

- Hydraulic equipment (1)

- Conveyor systems (1)

- Forklift trucks (1)

- Granules for plastics (1)

- Induction heating systems (1)

- Mechanical transmission - components (1)

- Oil filters (1)

- Plastics - industrial machinery and equipment (1)

- Steels and metals - forming and cutting (1)