- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stamping

Results for

Stamping - Import export

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Stampings (and stamped parts) are versatile and you find them in a wide range of applications for many different industries. Lesjöfors delivers stamped parts from our standard program as well as customized solutions.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Cold rolled strip is used in a variety of applications. It meets high demands on forming behaviour, dimensional tolerances and surface finish, which offers our customers decisive advantages! HFP cold rolled strip is ideally suited for all stamping, bending, drawing and deep drawing purposes. From ball bearing housings to roll cutting and punching strips, hose clamps, headlight reflectors, electrical equipment, office supplies and tubes to safety parts of all kinds, a wide variety of components can be manufactured for various industries. DC 01, DC 03, DC 04 according to DIN EN 10139 / mild steel - St 37/ special grades on request Depending on the customer's requirements, we supply treatment states from LG to C690.

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,3 – 4,5 mm spring-hardened Wire diameter: 0,3 – 7,0 mm soft Part length: customer specific after consultation Profiles other than round wire after consultation Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels Additional coatings available after consultation Meeting the closest tolerances Specialities Partial machining Stamping Thread cutting or rolling Fully automated mating with other parts Mounting and component manufacturing Processing of painted wires Rapid prototyping

Request for a quote

MECHASYS GMBH

Germany

Samples, prototypes and small series made of sheet metal Laser cutting, embossing and bending or punching including electroplating. Prototypes and small series - everything from a single source! We manufacture your individual sample parts, prototypes and small series mostly without any proportionate tool costs. This means that we are very flexible, efficient and cost-effective even with small quantities - in extreme cases from a quantity of 1. This is made possible by our modular bending kit. Everything from a single source: • raw sheets in stock • Laser fine cutting also from pre-punching tape using camera calibration technology • Embossing, bending, folding, pressing • Punching of functional areas • Progressive punching of medium quantities, depending on economic efficiency • Module assembly • CNC laser welding • Complete or partial electroplating by partner.

Request for a quote

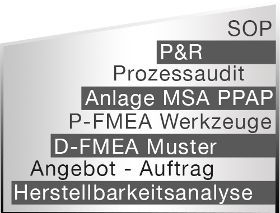

MECHASYS GMBH

Germany

In terms of project management, the respective feasibility study is a matter of course. No offer without a feasibility study. -An offer implies manufacturability; this is how our process is defined! - We live from prototypes and small series. Often there is no second assignment, so there shouldn't be any unforeseen surprises. Or at least only within a manageable framework. The combination of metal and plastic composite parts makes this a challenge from time to time. But you can be sure that here we draw on a wealth of experience that we would like to share with you.

Request for a quote

KRAMSKI GMBH

Germany

Compositing of stamped metal insert parts and plastic belongs to our core skills. With our know-how in both technologies, we are able to offer our customers projects and production that push the borders of what is technically possible, when synergistically compositing metal and plastic – and that from us as a single source.

Request for a quote

KRAMSKI GMBH

Germany

In stamping technology, many very different technologies can be integrated into the stamping process, such as assembling two or more parts, contact riveting, resistance and laser welding, laser marking of parts, or thread forming. Our high-precision tools, thereby, create a basis for production that is, over its lifetime, very high quality and economical. The stamping process is accompanied by a 100 % quality control of the functional design dimensions.

Request for a quote

KRAMSKI GMBH

Germany

Our core technologies, precision stamping and hybrid technology, are complemented by our special processes (parts cleaning, tumbling, brushing, sand blasting, polishing, laser marking, tape-and-reel, and more). Here, it is all about know-how-intensive processes and work steps, which we specifically use to improve the quality of our products and to hold our promise of KRAMSKI quality in every way.

Request for a quote

KRAMSKI GMBH

Germany

Customized single parts also belong to our services. Based on customer specifications, we manufacture extremely precise and quickly deliverable single parts using various material grades of carbide and steel. This is how we ensure one hundred percent interchangeability following the specifications. We can also contribute to your efficient production run with our high-quality replacement parts.

Request for a quote

KRAMSKI GMBH

Germany

The testing of a new design or process with maximized series-ready specifications – that is the job of our prototyping department. In close cooperation with our customers, we create a sample perfectly matched to the given framework. In addition to our own technologies, we can also integrate processes from our partners (e.g. electroplating or laser processing).

Request for a quote

KRAMSKI GMBH

Germany

Our development team works in cooperation with our project management department and engineering department by providing customized research and development. They take into account the fulfillment of the product requirements, as well as the perfect matching of the product to its subsequent manufacturing process. Through the early participation of our development team and the early implementation of their ideas during product development, our customers can save significantly.

Request for a quote

A + H THOMAS GMBH + CO. KG

Germany

We manufacture punched parts made of aluminum, stainless steel or plastic according to your specifications using high-quality punching tools on our modern punching machines. We can mill or laser smaller quantities or sample parts made of plastic or non-ferrous metals on our CNC machining center or our CO2 laser systems and label them as required.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES hand stamping tools are especially used for control stamping, numbering or as a center punch. They are usable as hand held tools or integrated units. These units are easy to use for flexible applications and the stamping inserts are quickly and easy changeable. These features make it to an indispensable tool for craft and industry.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES numbering heads were used to mark consecutive numbering, serial or model-number on almost all materials like steel, cast iron, aluminum, plastic etc. The application area ranges from the single production up to the integration in automatic production or transfer lines. The numbering heads can be combined with each other and extended with type holders and steel types. Besides numbers, letters or special engravings are also available. All BORRIES products are assembled with the highest precision and quality standard. It guarantees a long life time and a high stability.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our ACP Group offers over 400 different variants of stamped and lanced metal carriers. These carriers are used in a wide variety of sealing systems. Only high-quality raw materials such as steel, aluminium and stainless steel from certified suppliers are used for production. The Huehoco Group also offers a wide range of coating options. From functional to decorative coatings, our customers can choose from a wide range of products. We offer suitable bonding agents for almost all types of rubber and plastic compounds.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our special ability lies in the processing of metal strips pre-coated with adhesives. With this material it is particularly important not to damage the surface mechanically whilst at the same time not to impair the ability to bond. This skill enables us to supply stamped parts for bonding with rubber and/or thermoplastics, such as Vibration damping elements spring elements stabilizers functional parts components We guarantee a functional workability of the product for 6 months after delivery.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

maximum weight reduction high design flexibility predetermined breaking points can be defined

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HFP BANDSTAHL GMBH & CO KG

Germany

Stretching up to 100 % possible very light version large variety of designs

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Single Spine / Einstegig extremely flexible over three axes predetermined breaking points can be defined Free choice of spine width and positioning Double Spine / Two-webbed reduced "hungry horse" effect predetermined breaking points can be defined Free choice of spine width and positioning

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for precision machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The accessories of panel.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the accessories used in electronic panel control,after processing for a variety of color surface treatment.

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

BORNEMANN GMBH

Germany

Machine stamping presses with peg or threaded hole for mounting onto a press. For standard stamping presses we also offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference here. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination.

Request for a quote

BORNEMANN GMBH

Germany

Stamp mouldings for embossed or recessed stamping of aluminium or stainless steel sheets for the car industry. We produce the stamp mouldings in accordance with your data in soft or hard condition. Thanks to the high-quality structures, the movement between top and bottom dies is precisely coordinated. The design is based on your drawings or data.

Request for a quote

BORNEMANN GMBH

Germany

Sheet stamping dies, also called double stamping dies, with top and bottom parts for embossed or recessed stamping of sheets. For the production of these stamping dies, the strength of the sheet to the stamped is enormously significant. The movement between top and bottom stamp is designed according to these requirements. The parts are hardened in line with the purpose and delivered ready for use. We adopt the data from your drawings or drafts for production.

Request for a quote

BORNEMANN GMBH

Germany

Hot stamp dies or brass dies for labelling leather, wood, synthetics or paper. Labelling is carried out with or without colour film while feeding heat and gives the product an exclusive design. When making the brass die, we are guided by your requirements.

Request for a quoteResults for

Stamping - Import exportNumber of results

100 ProductsCountries

Company type

Category

- Package stamping machinery (17)

- Stamping - steels and metals (16)

- Stamping - machine tools (13)

- Sheet metals - stamping (5)

- Engineering - industrial contractors (5)

- Metal industrial presses (4)

- Sensors (3)

- Shaping - steels and metals (3)

- Metal straightening machines (2)

- Drawing - steel and metals (1)

- Alarms - security devices (1)

- Bags, plastic (1)

- Cables - accessories (1)

- Cold rolled steel strips (1)

- Embossing machine tools (1)

- Frames and mountings, photograph (1)

- Import-export - steels and metals (1)

- Industrial cutting machine tools (1)

- Knives, industrial (1)

- Machine tools, cutting - parts and accessories (1)