- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel tanks

Results for

Stainless steel tanks - Import export

BÜRKLE GMBH

Germany

Pendulum cup made of stainless steel V2A (1.4301) with extra-long, closed handle. The sample cup has no openings or undercuts up to an immersion depth of approx. 500 mm. The closed design of the shaft makes the scoop cup particularly suitable for sampling well water, sludge, waste water, liquid manure or similar. The sampler is particularly suitable for taking samples from basins, tanks, shafts, open bodies of water, etc. With the length-adjustable telescopic aluminium rods, sampling depths of up to 6 m can be achieved. The TeleSchöpfer telescopic rod with tools is a versatile sampling system. The interchangeable tools (angle cup, pendulum cup, bottle holder, stainless steel cup and landing net) are suitable for a wide range of applications. The tools are firmly connected to the telescopic rod by a practical snap connection.

Request for a quote

BÜRKLE GMBH

Germany

Sterilisable pendulum beaker made of stainless steel V2A (1.4301) for industry and water treatment. Beaker with scraping edge, capacity 1000 ml. Ideal for powders, granulates, pastes and slurries. Particularly suitable for sampling from basins, tanks, shafts, open water etc. Sample depths of up to 6 m can be reached with the length-adjustable aluminium telescopic rods. The TeleSchöpfer telescopic rod with tools is a versatile sampling system. The interchangeable tools (angle cup, pendulum cup, bottle holder, stainless steel cup and landing net) are suitable for a wide range of applications. The tools are firmly connected to the telescopic rod by a practical snap connection.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Description: The double diaphragm pump is suitable for industrial applications as well as for emptying drums, IBCs and tanks. * typical applications: Transfer from drums and containers, transfer of corrosive solutions and chemicals * integrated muffler up to model size AODD 1" * also available in the Pure version (5234-410) Features & Benefits * high hydraulic performance * maintenance-optimised design and simple installation * self-priming (even when dry) * absolutely oil-free * non-stalling operation * conductive version approved according to ATEX Directive 2014/34/EU, Category 2

Request for a quote

BÜRKLE GMBH

Germany

Robust pendulum cup made of stainless steel V2A (1.4301) for industry and water treatment. The cup automatically swings into the horizontal position. This means that nothing can spill. The small diameter (Ø 130 mm) also makes it suitable for deep and narrow shafts. Particularly suitable for sampling from basins, tanks, shafts, open water etc. Sampling depths of up to 6 m can be achieved with the length-adjustable aluminium telescopic rods. The TeleSchöpfer telescopic rod with tools is a versatile sampling system. The interchangeable tools (angle cup, pendulum cup, bottle holder, stainless steel cup and landing net) are suitable for a wide range of applications. The tools are firmly connected to the telescopic rod by a practical snap connection.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The automated assembly technology in the LIPP Double Seam System enables the fast construction of stainless steel tanks which has a positive effect on investment costs. Efficient production on site, minimal installation space and a short construction time are key features of this flexible construction technology.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The automated assembly technology in the LIPP Double Seam System enables the fast construction of stainless steel tanks, which in turn has a positive effect on investment costs. The benefit for you flexible construction technology with efficient production on site requiring minimal installation space and ensuring a short installation time. The smooth internal walls of the LIPP Digesters (largely without any internal attachments) ensure gentle, uniform mixing while keeping energy consumption low. The external heating system guarantees uniform temperature distribution in the digester. These mechanical and thermodynamic benefits with LIPP digesters mean short retention times.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

MUNICIPAL AND INDUSTRIAL APPLICATIONS WITH CHAMBER VOLUMES FROM 100 TO 7,000 M3 The LIPP UniCentralmix Digester with its central agitator is designed for industrial and municipal applications. The special feature of this tank, in addition to the central agitator, is the roof construction, with a high quality stainless steel diaphragm cover. The flexible LIPP System ensures each digester can be adapted to each individual application and customer requirements. KEY BENEFITS Energy efficient, central agitator Maximum leak tightness Flexible substrate composition High functional safety Stainless steel diaphragm roof without bolts External heating system available Production on site enables quick construction Low investment costs Low maintenance and durable High quality the world over PRODUCT SPECIFICATIONCENTRAL AGITATOR WITH BOLT LESS STAINLESS STEEL DIAPHRAGM ROOF At the heart of the LIPP UniCentralmix is a stainless steel tank (in Verinox) with a digester chamber

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WITH DIGESTER CHAMBER VOLUMES RANGING FROM 200 M3 TO 5.000 M3 The LIPP Universal digester which unlike the KomBio reactor does not have an integrated gas accumulator, is used for larger plants for industry and municipalities. The biogas accumulated is either directed into a KomBio reactor combined with the Universal digester or into a separate gas accumulator. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexible substrate composition Customisable pumping and stirring technology High functional safety Effective insulation results in low heating requirement Quick construction thanks to on site production Low investment costs Low maintenance and durable Consistent quality worldwide PRODUCT SPECIFICATION MODULAR PLANT CONCEPT The LIPP Universal digester essentially consists of a (Verinox) stainless steel tank with a modular design. Panel heating and insulation are fitted on the outside and are easily accessible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CR-M are designed for operation on stainless steel containers with filling openings of DN 400 mm and mixing volumes from 400 l up to 1,500 l. Depending on the viscosity of the mixing material, CR-Ms with fast running or gear reduced drives are available. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gear). The agitator shafts are balanced for concentric run after assembly. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening DN 400 when being inserted. The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives. All CR-M series mixers can be supplied as follows:

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

CR-M - Electric tote tank mixer for stainless steel IBCs The tote tank mixers CR-M are designed for operation on stainless steel containers with filling openings of DN 400 mm and mixing volumes from 400 l up to 1,500 l. Depending on the viscosity of the mixing material, CR-Ms with fast running or gear reduced drives are available. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gear). The agitator shafts are balanced for concentric run after assembly. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening DN 400 when being inserted. The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives. All CR-M...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

CRP-M - Pneumatic tote tank mixer for stainless IBCs The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for long-term use. The device is suitable for spraying lubricants or coatings with a high solid content. To change the container or clean it, the complete container cover with all attachments is lifted pneumatically.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic robot spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for continuous operation. The device is suitable for spraying lubricants or coatings with a high solid content. To change the tank or clean it, the complete tank cover with all attachments is lifted pneumatically.

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

Off gas analysis in bioprocesses delivers important informatione about respiratory activity like CTR from which actions for process optimization and scale-up can be deduced from. The BCP-CO2 analyzer with PA housing will help you to understand and control your processes better. The CO2 analyzer BCP-CO2 services for application in fermenters and bioreactors of any scale. No matter if you are working in big stainless steel tanks, shake flasks (using PES adapters) , disposable, single-use or parallel reactorsthe BCP-CO2 PA is easy to install, doesn´t need much maintenance and offers an integrated, automatic pressure and temperature compensation. BCP-CO2 PA measures directly in the process. Additional pipes are not necessary.

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

Off gas analysis in bioprocesses delivers important informatione about respiratory activity like CTR from which actions for process optimization and scale-up can be deduced from. The BCP-CO2 sensor will help you to understand and control your processes better. The CO2 analyzer BCP-CO2 services for application in fermenters and bioreactors of any scale. No matter if you are working in big stainless steel tanks, shake flasks, disposable, single-use or parallel reactorsthe BCP-CO2 is easy to install, doesn´t need much maintenance and offers an integrated, automatic pressure and temperature compensation. BCP-CO2 measures directly in the process. Additional pipes are not necessary. The extremely robust sensor has a IP65 aluminium housing and is well applicable under harsh process conditions.

Request for a quote

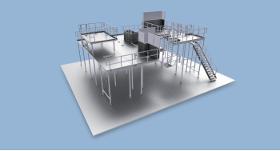

EDELSTAHL WEIMAR GMBH

Germany

Machine, work and operating platforms from stainless steel for aseptic and hygienic application - for example in the food, beverage, pharmaceutical or chemical industry. We offer the complete package including design and static calculation, manufacturing and assembly. We guarantee stainless steel manufacturing quality made in Germany, quick throughput times and competitive pricing. We are your reliable partner for stainless steel platforms and mezzanines!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The innovative SANHA installation system NiroTherm® combines high-quality NiroTherm® press fittings with a black sealing ring made from EPDM (=ethylene propylene diem rubber) and NiroTherm® stainless steel system tubes. The system is produced from the material 1.4301 (AISI 304). Due to the well-known corrosion resistance of stainless steel, NiroTherm® offers installers therefore a real alternative compared to conventional steels when it comes to closed systems in humid atmospheres such as screed. Since it needs considerably less isolation against humidity*, the installation is faster and labour costs accordingly lower. In addition to the system description, NiroTherm® system press fittings are marked on the outside with a red dot. * This does not affect thermal insulation necessitated by national energy efficiency laws.

Request for a quoteResults for

Stainless steel tanks - Import exportNumber of results

41 ProductsCountries

Company type