- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel manufacturing

Results for

Stainless steel manufacturing - Import export

HS UMFORMTECHNIK GMBH

Germany

We manufacture stainless steel branch pipes as well as stainless steel T-pieces with the following characteristics: 30°, 45°, 90° degrees (standard) material-no. AISI 304 / 304L at request also in aluminium at request also forming gas welded

Request for a quote

BÜRKLE GMBH

Germany

The micro spatula can be used for reliably measuring, sampling or processing small amounts of powder, chemicals, pastes, creams or active ingredients. The laboratory scoop is made of stainless steel and is manufactured entirely without edges, crevices or undercuts. This excludes the possibility of impurities or cross-contamination, since no product residue or cleaning agents can be deposited. The micro spatula is ideal for use in the pharmaceutical industry as well as food & beverage and cosmetics.

Request for a quote

FLEXOMAT GMBH

Germany

Flexomat know-how is the customer specific manufacturing of stainless steel corrugated hoses in various formats and dimensions. Flexomat stainless steel corrugated hoses are universally applicable and suitable for various media such as e.g. steam, water, oil, gas or chemical media. Corrugated hoses are applied to absorb movement and vibration or to compensate assembly inaccuracy. type SE: corrugated metal hoses, single-wall, medium wall thickness, standard pitch, one braid Typ SZ: corrugated metal hoses, single-wall, medium wall thickness, standard pitch, double braid Typ SEF: corrugated metal hoses, single-wall, medium wall thickness, low pitch, one braid Diameter DN6 up to DN300 Materials 1.4404 / AISI 316L oder 1.4541 / AISI 321 for the hose and 1.4301 / AISI 304 for the braid delivery length as standard length from stock or customer-specific-length after sprcification all common connectors according customer-specification DIN EN ISO 10380 DIN 3384 (DIN DVGW)

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

The blueglobe CLEAN Plus is the first cable gland to be certified to the high EHEDG standard and therefore can be used without risk in the food, pharmaceutical and chemical industries and in clean room technology applications. BGN also confirmed conformity of this cable gland with the relevant applicable testing specifications in test certificate NV 13132. The cable gland blueglobe CLEAN Plus has no cavities, gaps or external threads but has a smooth surface (roughness Ra < 0.8 μm) and rounded surfaces in contact with the wrench. PFLITSCH uses high-grade stainless steel 1.4404/AISI 316L to manufacture this product. All seals are made from plastics that comply with FDA 21 CFR §177.2600 and are suitable for being in contact with food.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Force-of-gravity separators, which are used as pre-filters or for the separation of large quantities of dust and swarf. Cyclone separator Cyclones are force-of-gravity separators. The separation principle is based on centrifugal force, which is produced by the tangential injection of the raw air. Cyclones are used as pre-filters or for the separation of large quantities of dust and swarf. The degree of separation of a cyclone is not normally sufficient to meet the usual environmental protection requirements. The cyclone exhaust air must be post-filtered in most cases. Product description A cyclone essentially consists of three parts: the intake cylinder, the cone and the immersion tube. In the intake cylinder, the raw air is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air stream and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube. Cyclones are usually welded sheet steel structures. Cellular wheel sluices or, in individual cases, double-gate sluices are used for the pressureless discharge of the material. In order to increase the cyclone effect, or the degree of separation, counter-spirals with a pipe connection can be placed on top of the immersion tube. Further options are, for example, wearing devices, explosion pressure relief devices, control flaps, level monitoring devices and manufacturing in stainless steel or galvanised sheet steel.

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel rod, which is manufactured completely from stainless steel (Ø 42 mm), is used to install building components and (sub)structures on a roof surface. Our ABS UniMount is a flexible solution which can be used to install solar panels and photovoltaic modules, air conditioning systems and similar components. It can can either be installed on a concrete or steel surface. Base plate (130 x 130 mm) + welded-on mounting rod (Ø 42 mm) Female thread (M 10) at the top end For steel surfaces with a depth of at least 5 mm For horizontal and vertical loads of max. 3 kN Incl. stainless steel installation set

Request for a quote

SERVOLIFT GMBH

Germany

Lifting, transporting and tilting drums and bins is a typical task especially in the chemical and pharmaceutical industrie as well as in food manufacture. SERVOLIFT, the original handling system, has been manufactured for approximately 30 years. It provides decisive advantages thanks to its two arms: unhindered view of the transport materials, exact and safe operation, uncompromising compliance with all hygiene requirements as well as a higher degree of reliability and cost effectiveness. Strong, maneuverable and easy to operate: the new SL 250 Technical description Free view of the carried load Loads up to 350 kg Explosion protection for zones 1/21 and 2/22 Lift up to 4,250 mm GMP-compliant construction, easy to clean and completely manufactured of stainless steel Faster and easier exchange of the gripper system for various drum types Space-saving due to its very compact design Very maneuverable in confined spaces Can be used everywhere due to its low weight Extendable versions...

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001. This high performance Hinge from EMKA is precision engineered for single door cabinets. The advanced hinges are manufactured from stainless steel for prolonged durability and feature a 180° freedom of movement for and 20 mm door return. The hinges are an ideal partner for a cost effective increase in productivity.

Request for a quote

JOSEF JASPER GMBH & CO. KG

Germany

We manufacture pressure vessels and process engineering apparatus from steel, stainless steel and aluminium. The design, manufacturing and acceptance comply with the common national and international regulations.

Request for a quote

AUWEKO GMBH

Germany

Public spaces require high-quality, durable solutions which fit elegantly into the overall picture. AUWEKO's CAPITAL series of bins are an elegant solution for getting litter effectively under control. The containers are manufactured in stainless steel or galvanised steel with powder coating and are available with an optional information space. CAPITAL litter bins are available as wall-mounted or floor-standing models with a capacity of 50–120 litres. Ashtrays can be integrated into the cover or on the side.

Request for a quote

MERA BELLOWS C/O ANSCHÜTZ VERWALTUNGS GMBH

Germany

Due to change in weather (wind, sun, snow...), pipe systems of solar thermal systems are subject to thermal expansion, to vibration, to make in short; various movements that have to be compensated in order to keep the system stable. Mera Bellows manufactures stainless steel expansion joints, formed from thin-walled seam-welded tubes, that are widely used for this scope of application.

Request for a quoteMÜLLER GMBH

Germany

The filling of drums and the transfer of their contents are special situations, since each time the product comes into contact with the environment. We manufacture stainless steel hoppers for different industrial processes. Symmetric and asymmetric hoppers with shut-off butterfly valves in nominal diameters up to 300 mm make the complete operation dust-free and waste-free, and are not restricted only to Müller drums. Various cones and discharge aids, from rotary hooks to pneumatic vibrators, contribute to a problem-free emptying process.And the beauty of it is that the stainless steel hopper is only fitted when and where it is needed. This saves space and is highly cost-effective. 3.0 Info Stainless steel hoppers Hoppers (modules to fit lidded drums) Size: To fit all Müller drums, available in Ø 120 mm to Ø 1200 mm Application: Filling, emptying, mixing, charging reactors, feeding production lines and tablet presses Product: Powders, liquids Shape: The right angle for your...

Request for a quote

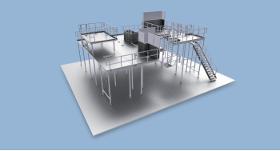

EDELSTAHL WEIMAR GMBH

Germany

Machine, work and operating platforms from stainless steel for aseptic and hygienic application - for example in the food, beverage, pharmaceutical or chemical industry. We offer the complete package including design and static calculation, manufacturing and assembly. We guarantee stainless steel manufacturing quality made in Germany, quick throughput times and competitive pricing. We are your reliable partner for stainless steel platforms and mezzanines!

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® Bend 30° with plain ends

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® pipe Bend 90° female/male

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan-ECO pipe 6 m rods

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® Bend 90° F/M-thread

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan Bend 90° M-thread/nut

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® Bend 90° female/male - long

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteResults for

Stainless steel manufacturing - Import exportNumber of results

159 ProductsCountries

Company type