- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- springs

Results for

Springs - Import export

PIERON GMBH

Germany

Dimensions Spring dimensioning according to customer request Material All spring materials Stainless steel Coating In-house phosphating Color code on the spring Additional coatings through external services Specialities Wave springs highly resistant against dynamic stress Wave springs highly resistant against static stress Minimal relaxation through heat treatment Automated setting- and force-inspection Customized dimensioning Axial installation space saving up to 50 % High spring rates with low tolerances

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,2 – 8,0 mm Outside diameter: > 120 mm after consultation All wire profiles feasible Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Clamping rings made of round wire or flat material Clamping rings with a stamp Rings with defined bendings Minimum burr cut-geometry Additional processing available after consultation Customer specific packaging Rapid prototyping

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,3 – 4,5 mm spring-hardened Wire diameter: 0,3 – 7,0 mm soft Profiles other than round wire after consultation Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels Additional coatings available after consultation Specialities Tight torsional tolerances Torsion springs with max. two coils (toggle springs) All kind of hook and leg configuration Rapid prototyping

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,2 – 8,0 mm Spring length up to 1500 mm Special profiles feasible Outside diameter max. 120 mm Customer specific spring shape Material All spring materials Coating All commonly coated spring steels In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Compression springs highly resistant against dynamic stress Compression springs highly resistant against static stress Minimal relaxation due to heat treatment Fully automated setting- and force-inspection Smallest force tolerances Customer specific packaging Assembling and mounting with other components Rapid prototyping

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: from 0,2 mm Spring geometry after consultation Material Stainless steel Copper alloy Customized solutions Coating Additional coatings through external services (e. g. gold-plated, silver-plated, tin-plated) Specialities Highest precision because of laser-welded spring ends Optimal contact properties because of inclined coils Automated manufacturing Customer specific packaging Rapid prototyping

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

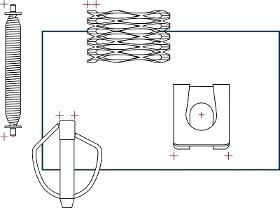

Compression springs is the most common type of springs. The majority of compression springs are cylindrical and linear, but to this group belongs also conical, barrel shaped, tapered out ends and more. The design can be adjusted to fulfill a wide range of requirements concerning spring characteristic.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Lesjöfors’ range of standard springs consists of over 10,000 different items. Our highly efficient store of standard springs guarantees high delivery reliability. All our standard springs have been posted as 3D CAD models, and are available for downloading.

Request for a quote

DIETZ GMBH

Germany

Wave springs developed to order: We work closely with you in the development of our wave springs for the intended application. Where necessary, we are pleased to assist you with processes ranging from dimensioning to verification to production. With the help of our specialist expertise, we will find the right solution for you together. We produce both single-turn and multi-turn designs with wavy and straight surfaces.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälische Drahtindustrie manufactures steel wire for springs for use in a wide range of applications automotive, mechanical engineering, window and door equipment, agricultural technology, furniture industry, screen wire for the filter industry, various industrial products.

Request for a quote

EM-TECHNIK GMBH

Germany

Check valves are used to prevent media from flowing back in systems or to protect equipment against media blow-back. The three types (with spring, without spring and COMPACT) allow for use in many different applications. The valve seat is supported by an O-ring and guarantees maximum safety and reliability.

Request for a quote

SPIROL

Germany

SPIROL offers Disc Springs pre-stacked in custom configurations (greased or ungreased) packaged in shrink wrap with a perforated tab for ease of insertion into the assembly. The Pre-Stacked Disc Springs are delivered intact which saves time, mistake-proofs the assembly process, and eliminates the mess associated with greasing the stack. Have an existing Pre-Stacked Disc Springs Application? If you have an existing Disc Spring Stack that you would like quoted, please Request a Quote. We are here to help!

Request for a quote

SPIROL

Germany

SPIROL offers a line of austenitic stainless steel Disc Springs in diameters ranging from Ø8mm to Ø71mm. Austenitic stainless steel is typically used for static and low cycle applications that require a heightened level of corrosion resistance. It withstands fresh water and atmospheric marine conditions very well, and is suitable for many other industrial conditions including acidic environments. This material will continue to work harden with use so cycle life is limited, but creep resistance is good. SPIROL supplies both single Disc Springs as well as Pre-Stacked Disc Springs in custom configurations, packaged in shrink wrap with a perforated tab for easy of assembly.

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

The mechanical back-up design uses SPIROL® Disc Springs. Under normal circumstances, the hydraulic system holds a constant pressure on Disc Springs stacked in series. If pressure fails to be maintained, the stack of Disc Springs decompresses to actuate the braking mechanism. A compression spring or wave spring is not capable of providing the force required (in the space available) to actuate the brakes. The reliability of this safety system is dependent on the consistent performance of Disc Springs. In this critical application, the Disc Spring’s performance and level of predictability improves product quality and ensures overall safety. SPIROL® Disc Springs have a high capacity to consistently store releasable mechanical energy. Visit www.SPRIOL.com to learn more!

Request for a quote

SPIROL

Germany

DEWALT’s lead design engineer for drills was tasked with designing a high power right angle drill that is lightweight, compact, and portable. The goal with the design was to maximize performance while minimizing the size of the tool. The design would incorporate a mechanical clutch built to limit maximum torque output to 70 ft-lbs. Absent the clutch, with the huge gear reduction of 75:1, the drill would be capable of producing a lock rotor torque at the spindle of 175 ft-lbs, transmitted directly to the operator of the tool. It was determined early on that the clutching thrust required in the space available could only be achieved by a Disc Spring design. Compared to conventional coil springs, Disc Springs offer a higher load capacity in less space. Additionally, longevity and reliability is a high measure of quality for professional tools used on a daily basis. The life and performance warranty of the tool was reliant on the Disc Spring design. Visit SPIROL.

Request for a quote

SPIROL

Germany

Disc Springs are conically-shaped precision components designed to be axially loaded. Disc Springs are often incorrectly referred to as belleville disc springs, belleville springs, belleville washers or simply conical washers. SPIROL offers the full range of DIN EN 16983 (formerly DIN 2093) Group 1 and 2 Disc Springs in Series A, B, and C. In addition to the DIN specified sizes, SPIROL stocks its own standard sizes with outside diameters ranging from Ø8mm to Ø200mm. SPIROL Standard Disc Springs were designed around the standardized calculations of DIN EN 16984 (formerly DIN 2092), and meet all material, dimensional tolerance, and quality specifications as laid out in DIN EN 16983 (formerly DIN 2093) yet offer an expansion in the diameter and thickness combinations that are not included in the DIN standard. Standard materials include carbon steel and alloy steel, both finished with a protective coating of zinc phosphate and oil.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Modern manufacturing faclilities using the latest in design and production technology ensure consistent, high quality, long life products that are competitive priced.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HFP BANDSTAHL GMBH & CO KG

Germany

Spring steel is a model of load-bearing capacity. Characteristic for this material group are homogeneous microstructures and optimal surfaces. It stands for above-average service life, dimensional stability and constant quality in every end product. Spring steel obtains its special properties through special treatment in the production process, whereby the even distribution of the carbon content is of particular importance. It undergoes several rolling processes and repeated heat treatments in numerous work steps - this is how we guarantee optimum quality for your products! C 67 S - C 100 S/➔ according to DIN EN 10132 - 4 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Multi-coil wave springs are made from flat-rolled spring wire that is coiled to a helical shape and the coils are at the same time given a sinus shaped wave form. The force-deflection relation is created by flattening out the wave form when the spring is compressed. The function is hence like a helically shaped leaf spring.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Many applications require two similar springs, but with one right-hand coiled and one left-hand coiled. In some cases, these two springs can be combined into a double spring, which has one right and one left-hand coiled spring body connected to each other.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Torsion bar springs is a good alternative to clock springs or helical torsion springs, when a rotational torque is needed in applications where the spring shall fit into a space that is limited radially, but with lots of space axially.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Most common ends are different types of end loops and hooks, there are also a wide range of other mechanical attachment possibilities such as coiled in and screwed in attachments. Examples are, half hooks, German loops, English loops, extended hooks, side hooks, side loops, screw plugs and screw shackles.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

The number of turns is individually determined and can be as much as 50. Different coiling techniques exist to give the material the desired curvature that matches the torque-rotation requirements. The spring has many similarities with clock springs, but have a much larger operating range in terms of number of turns.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Disc springs (also called Belleville springs) are geometrically a cylindrical washer with a slightly conical shape. It is used as compression spring and is the best solution when forces are high and travel relatively limited. This type of springs can or in parallel, which increases travel and/or force.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Constant Force Springs are manufactured from flat strip material and spooled to a specific curvature matching the needed pull force. There is practically no limit on extension speed and acceleration. The springs can be fitted in a number of ways and extended partly or completely.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Clock Springs – also called hair springs – is a torsion spring that is optimum for installation spaces that are limited axially, but with more space radially. They are made from strip material or flat rolled wire that is wound in a flat, spiral shape.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Flat springs are parts made of strip material where the material is stressed in the bending process and the relation between deflection and force is a vital part of the function. Their design can be varied extensively to fulfill both load-deflection and assembly requirements.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Dynamically dampened gas springs are commonly used in applications that do not allow the piston rod to be facing downward in the open position, while maintaining the ability for soft and controlled damping.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Lockable gas springs are commonly used in applications requiring the ability to lock out the stroke in a desired position without the need for external locking mechanisms. This is achieved by a unique piston design that separates the gas and oil chambers of the spring

Request for a quoteResults for

Springs - Import exportNumber of results

161 ProductsCountries

Company type

Category

- Springs (51)

- Disc springs (24)

- Import-export - steels and metals (21)

- Spiral springs (20)

- Screw cutting - steels and metals (20)

- Custom design springs (17)

- Helical springs (16)

- Coil Springs (13)

- Wire springs (9)

- Brakes, servo-brakes and accessories (8)

- Lifting equipment (5)

- Fasteners, metal (2)

- Wires and cables, steel (2)

- Components and parts for small household appliances (2)

- Electric motors and parts (2)

- Electrical & Electronic Components (2)

- Handling - Machines & Equipment (2)

- Measurement and control instruments (2)

- Metalworking - portable power tools (2)

- Hydraulic springs (1)