- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spot welding

Results for

Spot welding - Import export

WDM DEUTENBERG GMBH

Germany

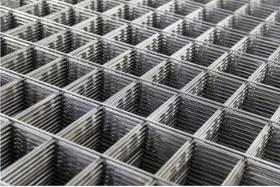

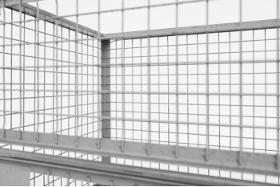

The central product of WDM Deutenberg are spot-welded wire meshes according to individual specifications. There are four different wire materials used to produce our wire meshes and wire mesh elements: bare wire, galvanized wire, aluminium galvanized wire and stainless steel wire. Our spot-welded wire meshes have different sizes from 300 x 250 mm to 8,000 x 2,400 mm depending on mesh width and wire diameters. Mesh widths between 20 mm x 20 mm minimum and 150 mm x 150 mm maximum and diameters from 2.0 mm to 18.0 mm are possible. The scope of application of our spot-welded wire meshes is very diverse. They are used in industries such as landscaping, agriculture, engineering, shopfitting, metalworking, food industry, electrical industry, construction industry or retail. Please call us for further questions under +49 (0) 38789 / 879-0 an or write us an e-mail to info@wdm-wolfshagen.de.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision machinery parts,Brass turning and milling.Electric zinc surface treatment

Request for a quote

SPANSET SECUTEX GMBH

Germany

Plastic for welding … Welding is often the simplest and best way of fastening. The range of different perforated plates offers a wide range of applications. Size and quantity of the welding joints depend on the substructure and must be defined on site. Please note that the perforated metal sheet can under no circumstances take over any static functions. The secutex buffer pad is simply disconnected by grinding away the welding spots. These are the advantages Simply weld onto the item to be welded No need for repeatable holes in the workpiece No holes in the secutex impact protection material Applications On all metal surfaces On thin metal walls Everywhere where screwing is not possible or screw holes are unwanted Examples Collecting basins Ramp protection metal boxes Container Forklift Gripper Girder protection Pallet truck 1. Perforated metal sheet, overhang at the side This version is suitable for welding onto flat surfaces and extrawide profiles of construction steel.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Touching-up damaged points on galvanised surfaces, for example after welding, drilling or cutting processes Priming of ferrous metals when zinc galvanising cannot be carried out. For example, in vehicle and ship repairs, in steel building construction, civil engineering and bridge building, in tank and overhead line construction, on grids, fence and traffic signal posts, exhaust systems, drain gutters Also suitable for spot welding thanks to the good electrical conductivity Advantages and benefits Highly effective due to active, cathodic corrosion protection Versatile use as durable corrosion protection at thermally stressed metal parts Highly economical due to low consumption and self-cleaning spray valve Supplements galvanising and forms a rough adhesive surface for subsequent painting

Request for a quote

KULLEN-KOTI GMBH

Germany

The STS-spiral roller brush range from Kullen-Koti contains all measurements from small to extra large and this unbeatable selection of diameters makes this brush a totally reliable tool for light brushing tasks. Due to the high fill density and precisely ground surface it achieves outstanding results. A flawless radial true runing is a requirement in most cases to achieve the desired brush effect. Therefore the brush cores are electrodynamically pre-balanced and re-balanced according to the required RPM after assembly of the spiral brushes. The balancing quality refers to quality grade G 2.5 as per ISO 1940. As core material we have available: mild steel, stainless steel, non-ferrous metal or plastic coated steel. Fixing of the spiral coils The coils are generally mounted onto the roller cores with pressure rings (PRB) in order to prevent the brush from roating on the core. Depending on the work and the rotation speed of the brush the coils can also be spot-welded or screwed...

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Cleaning discs FAPI-CLEAN provide very good results when grinding and cleaning metal, stainless steel, wood or plastic and can therefore be used as a preliminary stage for grinding/polishing. We will be happy to advise you by telephone or at your site whether the use of cleaning discs FAPI-CLEAN also makes sense in your company for your processes. Construction Cleaning discs FAPI-CLEAN consist of knitted nylon threads which have been soaked in synthetic resin and gently cured. They are available on fabric plates and for use on straight and shaft grinders. Applications The cleaning discs are suitable for cleaning and polishing all surfaces. Scratch-free removal of paint, rust, scale and welding spots from metal Cleaning wood and plastic Remove paint from wood Free stainless steel from blue colouring Dimensions For cleaning discs FAPI-CLEAN the principle applies that they may only be used in conjunction with a clamping shank. Notice: For cleaning discs, the principle applies...

Request for a quote

WDM DEUTENBERG GMBH

Germany

Spot-welded wire meshes from WDM Deutenberg offer the required stability, sustainability and safety regarding production, further processing and usage of your transport equipment.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Designed to be accurate, repeatable, and easy to operate IEC584 color standard (green) for type K thermocouples Strong crimped plug/cable attachment CLAMP thermocouples clip to non-ferrous components Clamp Surface for measuring substrate temperature Clamp Air for measuring ambient temperature ADHESIVE PATCH thermocouple Ultrafast response, single strand and PTFE coated Minimal thermal mass – ideal for small items or plastics EXPOSED-JUNCTION thermocouples for use on test pieces that are left permanently rigged Attached to the substrate by spot welding, soldering, use of high-temp tape or screw EXPOSED-JUNCTION THERMOCOUPLE – HIGH-TEMPERATURE featuring a glass-fiber cable Attached to the substrate by high-temp tape or screw, or spot-welded into position Placed at critical points on the product, thermocouples enable temperature profiling with a DATAPAQ Oven Tracker. All DATAPAQ probes conform to the highest standards and provide the most accurate data possible.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

With zippers it is possible to realize simple bag packages with re-sealing option. With the Zipper Crush module, Herrmann Ultrasonic provides a suitable solution for many different types of zippers, for fixing the zipper ends at the left and right sides of the bag by means of spot welding. Tools with high-quality finishing in combination with heavy-duty generators ensure great output quantity.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The most simple way of welding thermoplastic materials is to use the ultrasonic manual welding device. This is particularly well suited for applications in prototype design, for processing of single products, small series and repairs. Regardless of caulking, swaging, staking, cutting, or spot welding, the HSG ultrasonic manual welding device is easy to use, provides variable power rating, and can be equipped with all types of conventional sonotrodes (35 kHz).

Request for a quote

ALPHA LASER GMBH

Germany

The laser welding systems of the AL series can be used universally. They might be integrated into existing machine structures or used with an application device for manual welding. In combination with our NC-controlled laser machining table AL-T you get a real professional solution. We offer the required performance class for every application. You can choose between 75 and 900 W. There is a wide range of processing lenses and equipment options for these laser systems. Regardless of whether you use a simple 90 ° deflection lens, the tilt-swivel lens or our circular welding lens - the laser beam always reaches the desired point on the workpiece with pinpoint accuracy. Additional equipment options are optionally available for the AL, such as: • Micro welding device for a welding spot diameter <100 µm • Rotary axis module for cylindrical welds • automatic wire feeder • Workpiece holder • camera system •…and much more

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Copper zirconium for welding applications spot welding

Request for a quote

EWM AG

Germany

— Modular plasma/TIG welding machine with Comfort 2.0 P control — Plasma and TIG welding — Plasma and pulsed TIG welding — Plasma and pulsed TIG welding up to the kHz range allow a high welding speed with minimal heat input using a constricted arc — Plasma and TIG welding current adjustable in 0.1 A increments — Pilot arc current adjustable in 0.1 A increments between 2–15 A — The pilot arc current can be adjusted at four operating points during the welding process (beforehand, during, and following welding, as well as during pauses in welding) — Non-latched/latched operation — Spot welding/tack function (spotArc/spotmatic) — Spotmatic – reduce the time required for tacking by up to 50% (TIG only) — Adjustable up-slope and down-slope time — 3.5 m mains supply lead with 16 A shock-proof plug

Request for a quote

KLN ULTRASCHALL AG

Germany

For the assembly of plastic parts, which differ in size and condition and would therefore not be suitable for standard machines, we recommend the use of special equipment with several ultrasonic units for ultrasonic welding and processing methods. • Riveting • Welding • spot welding • punching • flanging • cutting • embossing • printing Multi-head systems These machines can also be used to accomplish complex tasks, e.g. the combination of different welding techniques, like spin welding and hotplate welding and for numerous automated processes

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The new CX series all-purpose large robots are equipped with a light and large arm with a hollow structure and a new universal control unit. They are large all purpose robots for a variety of applications for assembly, spot friction welding, machine loading, material handling, material removal, sealing/metering, spot welding, material handling, etc.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The new CX series all-purpose large robots are equipped with a light and large arm with a hollow structure and a new universal control unit. They are large all purpose robots for a variety of applications for assembly, spot friction welding, machine loading, material handling, material removal, sealing/metering, spot welding, material handling, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAWASAKI ROBOTICS GMBH

Germany

With the new model BX200X, Kawasaki Robotics is responding to the increasing demands of the European market - among others in the areas of spot welding and handling: The BX200X offers the same performance, hollow wrist design and load capacity of 200 kg as the BX200L - but extends the effective reach of the robot from 2,597 mm to 3,412 mm. A decisive advantage: The configuration of the BX200X is largely based on the BX200L and BX300L models - so the existing BX spare parts can also be used for the new model. Like the other robots of the B series, the BX200X also offers maximum performance on short distances, as is required especially for the automation of spot welding processes.“

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B-series from Kawasaki is a robot specifically manufactured for spot welding. Its compact, and robust design with a housing constructed out of durable materials is the combination of the sleek R-series and the robustness of the Z-series. This would make the B-Series capable of offering maximum performance and is highly resistant to vibration as well as utilizing a heavy-duty motor. It is capable of having a maximum payload capacity of up to 200 kg and a maximum reach ranging from 2200 up to 2597 mm as well as having a repeatability of ± 0,2 mm and a maximum linear speed of 5000 mm per second.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

Using Kawasaki's extensive experience in automation and advanced technology, the Z-Series heavy-duty robots were developed. The designs are robust and low-maintenance, being directly responsible for optimizing the efficiency of the production lines in general industry and automotive applications. They have a payload of 165 kg, a repeatability of ±0.3mm and a maximum linear speed of 2,500 mm/s. The horizontal reach is 2.651mm and the vertical reach is 3,415mm. They can be used for a variety of applications including assembly, dispensing, machine tending, material handling, material removal and spot welding.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The future is lightweight – with Flexweld®. Flexweld®, the unique joining process, offers countless benefits, with one of the biggest advantages being the considerable weight reduction in the age of lightweight construction. Moreover, no additional machinery is required to incorporate it into an existing car body assembly line. significant weight saving, which provides long-term reduction in CO2 emissions joins lightweight materials to high-strength metals can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment no additional qualification for workers needed complete system including full feeder and processing technology mixed production possible by adapting the spot weld gun software

Request for a quoteResults for

Spot welding - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Industrial robots (8)

- Automation - systems and equipment (6)

- Gratings, metal (2)

- Steels and metals - welding and brazing (1)

- Laser - cutting and welding machines (1)

- Foundries - copper, bronze and brass (1)

- Mechanical transmission - components (1)

- Radiators, engine (1)

- Sheet metal and strips, tinplate (1)

- Silicones (1)

- Temperature sensing devices (1)

- Ultrasound systems - Processing plastics (1)

- Welding, soldering and brazing - equipment and supplies (1)