- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special flanges

Results for

Special flanges - Import export

IGUS® GMBH

Germany

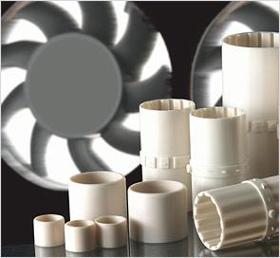

iglidur® L250: For fast rotations Bearings for fast rotary motions like, for instance, in fans and small motors. iglidur® L250 is available as cylindrical bearings and plain bearings with flange. specially developed for fast rotating applications Very low coefficients of friction Excellent wear resistance

Request for a quote

IGUS® GMBH

Germany

iglidur® flange bearing d1 [mm]: With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. When to use iglidur® flange bearings? When you want a screw flanged bearing When a clip bearing solution is not satisfactory as a sheet metal feedthrough When there is a housing with very rough tolerances When the tight fit of a press-fit bearing is not sufficient as an axial securing When not to use them? When an additional angle compensation is required igubal® flange bearing When a screw connection is not possible iglidur® clip bearing When a large guide length is necessary iglidur® G General features With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered. Installation Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation. Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X The mounting of the iglidur® flange bearing: Simple and safe iglidur® flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

MDM Double flange bearing b1 [mm]: When to use it? When the axial safety of the iglidur® clip bearing is not sufficient When there is a housing with very rough tolerance When high axial forces must be absorbed When not to use it? When an automated assembly is required iglidur® MKM When the iglidur® clip bearings offer adequate tightness iglidur® clip bearing When a large guide length is necessary iglidur® MKM MDM Double flange bearing b1 [mm]: Special features Large flange surfaces Symmetrical flange Easy installation Easy to clip on Undetachable after cataphoretic painting process Special option possible

Request for a quote

IGUS® GMBH

Germany

Special features press fit Both sides axially mounted Tolerance compensation of the sheet thickness Easy installation Axially prestressed Special option possible MKM Double flange bearing d1 [mm]: Special features press fit Both sides axially mounted Tolerance compensation of the sheet thickness Easy installation Axially prestressed Special option possible Press in, flange, finished: loss secure, axially mounted When to use it? When a flanged bearing is needed When the housing bore is more than 4 mm long When the axial safety is not ensured by press fit When a two-side flange is required as a thrust surface When not to use it? When maximum compressive strengths are required iglidur® G When a simple press-in bearing is needed iglidur® M250 When a clip-on sheet metal feedthrough is sought iglidur® G MKM Double flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]: iglidur® clip bearings are especially intended for the shaft bushing through plates. For this reason the bearing has a flange on each of the two front sides. After the clip-on the bearings are secured on both sides in the plate. The clip bearings have chamfered slot on the side that enables the mounting of the bearing on one side. After the mounting the bearing straddles and lines the bore in the plate. The shaft prevents the clip bearing from slipping out of the bore. The bearing cannot slip out of the bore even in axial movements. Extremely simple mounting through lateral slot Maintenance-free and self-lubricating Good flexibility in punch hole Good abrasion resistance Quiet operation Suitable for rotary and linear movements Extendibility through the slot Undetachable through double flange Special dimensions possible Plate thicknesses from 3 mm to 4 mm available from stock Material: iglidur® M250 Special properties of the iglidur® clip bearings iglidur® clip bearings are made from the most abrasion-resistant material, iglidur® M250. iglidur® M250 is a bearing material for rugged, wear-resistant bearing systems for medium loads. The bearings are self-lubricating and can be used dry. If required the bearings can also be lubricated. The material iglidur® M250 is resistant to all common lubricants. The iglidur® clip bearings are the ideal solution for bearing functions with low loads. The easy mounting makes it ideal for applications with difficult bearing locations. Compressive strength The permitted static surface pressure of iglidur® M250 amounts to 20 MPa at room temperature. Due to the good adaptability to uneven surfaces of the bearing housing, a high pressure load capacity of the clip bearings persists even in punched holes. For the most small bearing surfaces, the good vibration dampening properties and the insensitivity to misalignment are of primary importance. Surface speeds Clip bearings are particularly wear resistant in slow rotating, oscillating and axial motions. You can find the maximum gliding speeds for the various motions for the iglidur® M250 material under the materials data link shown below. A lubrication at installation or continuous lubrication raises the permitted surface speeds. Clip bearings are available from stock in dimensions of 3 to 25 mm. Fixation Triflex RS For mounting, the bearings are laterally pressed together with the large flange. The chamfered slot makes the bearing spiral-shaped, whereby it can be easily inserted in the plate. The remaining slot in the attached clip bearing can compensate for linear expansions of the circumference. Thus narrow bearing clearances are possible with clip bearings. The bearing clearance is dimensioned in such a way that in a housing bore with a nominal diameter, a shaft made with the same nominal diameter turns easily. The clip bearing can be used in H-tolerance housings up to H13. The turning of the clip bearing in the bore is also permitted. Operating temperatures The wear resistance of the iglidur® clip bearings are excellent with operating temperatures till 80°C. Even at low temperature the bearings remain elastic and abrasion resistant. When to use it? When a sheet metal feedthrough is required When the bearing should be captively clipped on in a drill hole with rough tolerance For rotating, linear and pivoting movements When a quick-mounting bearing solution is sought Clip bearings application examples When not to use it? When constant temperatures of more than +80°C occur iglidur® G When a high-precision bearing is needed iglidur® J When the housing bore is more than 4 mm long iglidur® Clips 2 iglidur® MKM When very high surface pressures occur iglidur® G iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]:

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAISER-MOTOREN GMBH

Germany

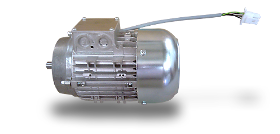

Unexcited synchronous motors Reluctance motors are used in textile machinery as drive for godets and spinning pumps. In general they are used in inverter application as single drive or group drive. Reluctance motors can be realised for any voltage/frequency ratio U/f. Speed >15.000min1 is possible. A great no. of variations concerning special shaft, flange bearing and housing is available. Reluctance motors are available for hazardous locations in flameproof design.

Request for a quote

FÖHRENBACH GMBH

Germany

The series of RT2A distinguishes by compact design with integrated precision roller bearing and worm drive. The rotary tables are sealed, IP 50 and can be driven in all fitted positions. For the mounting, standard drilling plans and special mounting flange and clamps can be used. Different limit switches are available: Standard: reference impulse, PNP-NC, 2 channel.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

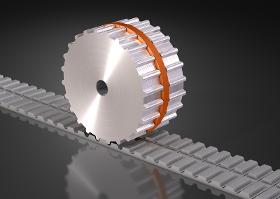

easy drive® track timing belts can be made from the complete range of polyurethane and neoprene timing belts: in open lengths, endless welded, for form belts, endless Flex or wide timing belts, in almost any length and width. The directional guiding, with groove in tooth, is either already integrated in the timing belt during production or added later. These timing belts exhibit the same properties as standard timing belts. However, in addition, axial movement is prevented and the zero-play guiding leads to high directional stability. Advantages • Universal application instead of flanged pulleys or special toothed belt guides • Can be used with any tooth shape or belt pitch • Can be combined with any material – steel, aluminium, grey cast-iron or plastics • For polyurethane and also for neoprene timing belts • Maximum directional stability, without lateral play, inaccurate running or drift

Request for a quote

KULLEN-KOTI GMBH

Germany

Our sealing brushes are available in many forms and with a wide variety of profiles. These profiles can also be used as mounting flanges. The special types consist of 11 types of sealing brushes which we can produce in a large range of variations on your request. You can choose: - All fill types, e.g. natural bristles and hair, plant fibres, synthetic filaments and wires.- The quality of the backing material, e.g. galvanized steel, stainless steel (1.4301; 1.4571) or brass.- The trim height (BH) (free bristle length- The overall length from a few centimeters to the maximum length which can be transported. We also can supply all sealing brush types with fixing holes in the holding flanges, e.g. 22 available sizes of round holes and 13 sizes of elongated holes. Don't hesitate to ask us for other dimensions of fixing holes, too.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

KB Schmiedetechnik GmbH in Western Germany has decade long experiences in the production of forgings for the energy market. Examples: •Forgings for nuclear power plants and hydrogen technology •Forged valve parts for nuclear and hydrogen applications •Forges components for nuclear fission and fusion reactors •Non-standard flanges and fittings of stainless steel like 316L or duplex •Special materials resistant against neutron or hydrogen embrittlement •Acid-resistant forgings for molten salt applications like fluid reactors or solar thermal power plants. In addition to this KB hold 5 certifications for the international maritime industry: •American Bureau of Shipping (ABS) •Bureau Veritas Marine & Offshore (BV) •Det Norske Veritas (DNV) •Lloyds Register (LR) •Nippon Kaiji Kyōkai (ClassNK) Examples are forged parts for industrial valves, boiler and pipeline construction. This includes various valve components, pipe connecting elements and special flanges.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

We supply from our existing stock Kalefeld elprom- aluminium flameproof motors / hazardous motors Ex de IIC T4 in frame size 56 - 132 ( 2- and 4- poles ) 0, 12 - 1 1 kW . All motors on stock are with Ptc thermistors and fixed bearing . Other frame sizes and versions are available within 4-5 weeks after receipt of order . Special applications Mechanical variants Protection IP56, IP65, IP66 Special flanges and shafts Without terminal box Uni-directional bearings, locked bearings or special bearings Terminal box on side SPM-vibrations measurement

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

RAEL, founded in Genoa in 1969 as a electric motors repair and rewinding company, has become an established name in project and production of electric motors for potentially explosive atmosphere. Since 1986 the company grew considerably and moved itself to Predosa where both production and offices are actually located. We supply from our existing stock Kalefeld RAEL- aluminium flameproof motors / hazardous motors Ex de IIC T4 in frame size 56 - 132 ( 2- and 4- poles ) 0, 12 - 1 1 kW . All motors on stock are with Ptc thermistors and fixed bearing . Other frame sizes and versions are available within 4-5 weeks after receipt of order . Special applications Mechanical variants Protection IP56, IP65, IP66 Special flanges and shafts Without terminal box Uni-directional bearings, locked bearings or special bearings Terminal box on side SPM-vibrations measurement

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

Cemp offers custom-made solutions. The main customers are the chemicals industry, pharmaceutical industry, power plants and minings. Further fields of application are the on-shore- and off-shore plants as well as the shipbuilding industry. The name Cemp stands everywhere for guaranteed security against explosion of dangerous dusts and gasses . We supply from our existing stock Kalefeld cemp- flameproof motors / hazardous motors Exd(de) IIC T4 in frame size 63, 2-poles up to frame size 160, 2-poles (0,18 – 18,5 kW) and frame size 63, 4-poles up to frame size 180, 4-poles (0,12 – 22 kW). All motors on stock are with Ptc thermistors. Other frame sizes and versions are available within 2 -8 weeks after receipt of order . Cemp Explosion Proof Motors / hazardous motors available in IE1 and IE2 High Efficiency Special applikations Mechanical variants Protection IP56, IP65, IP66 Special flanges and shafts Without terminal box Uni-directional bearings, locked bearings or special bearings SPM-vibrations measurement Electrical variants Special voltage and frequency Heaters Bimetallic thermal protection (NC, NO), thermistor (PTC), platinum resistor (PT100) Single-phase with permanent capacitor Single-phase with centrifugal switch Accessories Forced ventilation (IC416) Encoder 100 - 10000ppr Bearing sensor Breaks D.C. disk brake A.C. disk brake Hand release of brake Reverse braking function (braking when energized - frame size 63-100)

Request for a quoteResults for

Special flanges - Import exportNumber of results

14 ProductsCountries

Company type