- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- solutions in

Results for

Solutions in - Import export

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Since 1934 working with elastomers, we have developed special know-how in development and manufacturing in the field of technical hose products. Hoses Hose systems Moulded articles Rubber-metal bonds Expansion joints Special Versions As individual components or as combinations. Here, our experts unleash their creative powers and problem-solving skills. The main features of these customer-specific versions are top quality and high degrees of innovation and individualisation, directly maximizing the benefits to the customer. The following pages give some insight into the wide range of technical hose products and possible solutions to problems. Please do not hesitate to contact our technical sales department for more information.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Smooth final assembly The many different processes included in final assembly require precisely timed provision of parts and ergonomic support for manual work. Your advantages using Lödige solutions during final assembly Ergonomic work platforms Connection to high-bay warehousing Efficient preparation of different assemblies Linked materials handling systems Quick access to assemblies in intermediate storage Automation

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Quality at every level Safe transport and short throughput times — Lödige‘s material handling solutions easily accommodate all the demands made on them whether within the paint shop or in provision and intermediate storage after the painting process. Your advantages using Lödige solutions in the paint shop: Materials handling in multiple dimensions Connection to intermediate store Connection to body shell store Work stations Internal and external materials handling systems Materials handling systems and control technology from one source

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Fully automated storage In the automotive industry, storage in high-bay warehousing and precise, sequential provision are a vital part of the production process. Your advantages using Lödige solutions for efficient storage and order picking Custom-made racking systems Optimum use of space Storage for every sort of component Connection to internal materials handling systems Storage, materials handling and control technology — all from one source Quick and safe storage

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Profitable turn-key systems Accuracy, reliability and throughput are essential for the success of any material handling in industrial processes. Lödige Industries provides integrated solutions for an efficient material flow from goods-in, through the production process and goods-out, including tracking and stock control functions throughout. We plan, install and commission these solutions and provide an effective life-cycle service support to strengthen your competitive edge. Working closely with our customers we plan, simulate and implement conveyor solutions and turn them into profitable turn-key systems. Thanks to our industry-specific expertise, we optimise your material flow operations, increase the performance of your system and help to reduce operating costs significantly. We are unique in providing the complete solution with in house expertise: System analysis, planning, design, manufacture and supply of material handling systems, management software, installation, commissi

Request for a quote

SITEMA GMBH & CO KG

Germany

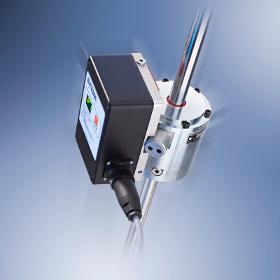

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

SITEMA GMBH & CO KG

Germany

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

SITEMA GMBH & CO KG

Germany

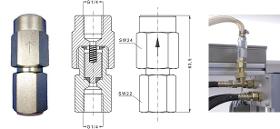

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

More space to work – let the rods out! In particular applications, it can be necessary that the rod leaves the clamping head, e.g. for reasons of accessibility or restrictions regarding space that do not allow a rod that is permanently in place. Especially in applications where moulds are closed and kept closed against high forces with the SITEMA PowerStroke, it is a big advantage when the rod can leave the clamping head. Thus, the rods are no obstacle when taking finished parts out of the mould or when handling parts. With certain modifications, most of our series can be adapted as special designs to allow the rod leaving and re-entering the clamping head. We have already realised a great number of such solutions for vertical and horizontal applications. Contact us for more information!

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quote

SITEMA GMBH & CO KG

Germany

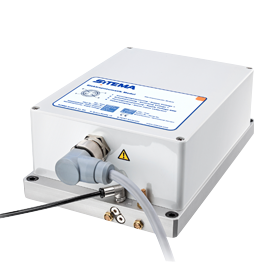

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

SITEMA GMBH & CO KG

Germany

In particular applications, it can be necessary to hold high axial forces and torque at the same time. For pneumatic operation, our Locking Unit series KFPD meets this demand. Depending in the size, forces / torques of 12 kN / 120 Nm or 30 kN / 500 Nm can be held securely. The “normal” SITEMA Locking Units KFH are already able to hold smaller torque. Example: 280 Nm with, at the same time, an axial holding force of 100 kN on rod diameter 56. In case higher torque needs to be held, SITEMA’s special design series KFHD can help. With this design, it is possible to hold torque with a factor of 10 higher compared to the standard KFH unit. Example: 2800 Nm with, at the same time, an axial holding force of 100 kN on rod diameter 56. Whether the operation is pneumatic or hydraulic, the application is limited to static holding. The KFPD and KFHD can prevent a rotation from starting, but are not suitable to brake rotating masses.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

For installation of pipe clamps with excellent optical characteristics Suitable for installation on walls, carports, winter gardens and dormers of roofs Can be used on concrete, wood, plastic and sheet metal surfaces Can be fixed with wood screws, screws for sheet metal or blind rivets Available surface: Zinc plated We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

MICRO-EPSILON

Germany

The rubber processing industry, as well as the tire production process is supported by Micro-Epsilon with a range of systems for inspection, monitoring and control of miscellaneous processes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICRO-EPSILON

Germany

In addition to pure color measurements, intensity measurements, completeness and presence checks or the evaluation of surface properties are also possible with the color sensors from Micro-Epsilon. These powerful colorSENSOR CFO sensors enable 100% control in demanding, industrial measurement tasks and provide precise measurement results.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Gas storage systems by Lipp have been successfully installed in more than 300 projects in Germany and worldwide. The gas storage capacity extends from 30 to 5,000 m³. The gas resistant PVC gas holder is protected by a galvanised steel cylinder. The self supporting roof is made of 1.4301 high grade stainless steel. The Lipp gas holder is offered as a complete system, including sensors and built in parts as well as steel construction, and can be easily integrated into an existing system. The main area of application of the Lipp gas holder is municipal waste water treatment plants and landfills which want to balance out fluctuations in gas production and at the same time need a buffer store for possible downtimes. A further gas holder may also be of interest for direct marketing of biogas, where feed in at certain times is necessary. The Lipp gas holder is especially attractive when considering the fact that electricity cannot be stored. But (bio) gas, which is used for power generation

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Depending on the industrial sector, more or less complex processes take place with more or less difficult media. These media are needed either for the production process itself or for supporting processes and can have very special properties. Thanks to the VERINOX used, Lipp can tailor the tank material exactly to medium and process and thus offer the best technical and economic solution. Parts and accessories can also be individually selected and installed according to the project. This means that Lipp system solutions can be considered both for simple solutions such as part of a fire protection system, but also for complex requirements, such as in the pharmaceutical and beverage industry. So much flexibility in terms of the possibilities for use is a powerful argument for cooperation with Lipp. Engineering offices gain a partner who covers a wide range of applications and provides the same high quality worldwide.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

ATMOSPHERIC PRESSURE, MAINTENANCE FREE AND PROTECTED AGAINST EXTERNAL EFFECTS The pressureless gas storage system of Lipp is used for the storage of gas produced on landfill sites, waste water treatment plants and also as external storage on biogas plants. The system is determined by its robust and technical advanced construction where the gas balloon is protected by a galvanized steel tank. This protects the balloon against UV light and also other external factors. The system is mostly utilized at landfill sites or WWTP to buffer the gas before its further processing. The experience gained during the past decades has improved the complete system and the single components and makes it a perfect choice for end users and general contractors.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR MUNICIPAL WASTE WATER TREATMENT Lipp has for many decades been an established partner of municipal waste water treatment plants, engineers and general contractors in the field of tank and system solutions for municipal waste water treatment. Due to their method of construction as well as flexibility in the choice of materials and ideal diameter – height ratios, Lipp tank and system solutions are especially suitable for the needs of small to large sewage treatment plants. They are ideally tailored to one another, but may also be embedded as individual island solutions into existing systems and are therefore equally popular with planners and end users alike. The stainless steels used and the double seaming guarantee maximum water tightness and durability with low maintenance for a wide variety of waste waters, slurries, process liquids and gases. The versatility in terms of the system solutions offered for municipal waste water treatment plants

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp tank and system solutions for municipal waste water treatment have been realised in close cooperation with well known design companies and end customers since the 1980s. In addition to municipal waste water treatment plants in Germany, Austria, Switzerland, France and other European countries, the Lipp system has already been successfully installed in many Asiatic projects. Lipp waste water tanks are offered in variable sizes and with individually adapted features (material, covers, additional equipment). Our success lies in professional management and close cooperation with all stakeholders over the entire project period. Reliable tank solutions, timely installation and numerous reference plants both in Germany and worldwide make Lipp an important partner in municipal waste water treatment.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

The search for solutions in the field of process engineering systems and methods presents us with new challenges every day. Electric heaters for the direct thermal treatment of incoming air in air conditioning systems or as preheater or afterburner for intake air in industrial equipment using intelligent processadapted control systems are gaining an increasing acceptance

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Settling and floating layers are avoided by horizontal and vertical mixing. Before plant construction, coordination takes place with the future plant operator to determine the optimum stirring technology based on the respective substrates. Operational safety is ensured by the closed reaction chamber, the external drive for the agitator and the externally mounted electric drives. Variable dimensions and substrate flexible stirring technology also allow the use of difficult substrates. The wall heating system, externally mounted on the fermenter wall, ensures optimum fermentation conditions and a high gas yield. FAST ASSEMBLY – LESS COST Low installation costs are possible by using the Lipp dual seam system and on site production. If the foundation slab is provided along with assistance during assembly, costs fall still further.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF SLURRY Following the further development of the Lipp dual seam system and the container material it was possible not only to build silos for bulk materials, but also silos for the storage of liquids, such as liquid manure. Since slurry is also rather more aggressive and can attack concrete or similar vessels, especially over the years, Lipp always offers its system solutions for the storage of slurry in principle in V2A stainless steel (1.4301), when it is clear that the tank will remain open. Possible changes are also taken into account with the customer during the planning process and in case of a future modification of the slurry tank consideration is given to an alternative material (V4A) or the possibility of a subsequent roof construction. Thus, the container retains its flexibility and can later be converted into a fermenter, secondary fermenter or other container.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF CEREAL PASTE AND SUGAR BEET Lipp plans and sells storage systems for biomass such as cereal paste or sugar beet under the brand names LIGAVATOR and BETAVATOR. These systems are generally gas tight and both roof and container base (optional) are made of solid stainless steel, since the stored media can give rise to very aggressive juices and gases. With this type of storage the substances are preserved and can be used over a very long period. Automatic withdrawal and substrate delivery can also be installed in the following systems by an appropriate control system. APPLICATION EXAMPLES AND REFERENCES In addition to pure crop storage, the Lipp LIGAVATOR / BETAVATOR systems are mainly used as substrate storage for agricultural or industrial biogas plants, and are installed before the fermenter for appropriate substrate supply. They allow largely automated control of a biogas plant, as there is no need for a regular manual substrate supply.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR SILAGE SILOS The Lipp dual seam system was and still is the basis for Lipp’s sustained success over the last few decades. Silage silos were already being built for agriculture with this system in the 1960s. The Lipp dual seam system is still employed today for the construction of silos and system solutions used for the storage of silage. In addition to pure container construction, system solutions for silage silos also include other components that go far beyond the scope of supply of a simple container manufacturer. APPLICATION EXAMPLES & REFERENCES Lipp system solutions for silage are used for storage and preservation of silage in an above ground, cylindrical container. Corresponding filling and extraction systems, roof and floor structures round off the scope of supply. A large number of the silage silos installed decades ago are still in operation today and provide proof of the high quality standard and extremely long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

BIOGAS FOR INDUSTRY, MUNICIPALITIES AND AGRICULTURE In addition to tank construction, LIPP built the first biogas plant in Germany in the 70’s. Furthermore, LIPP was one of the first companies to develop and sell small biogas plants in the early 80’s. By steady advancements in production technology and the materials used, as well as extensive experience in process engineering LIPP has installed in collaboration with its partners, hundreds of biogas plants in Germany and worldwide. The majority of these projects are still in operation and ensure proof of the high quality and the technical and economic performance of Lipp’s system solutions. LIPP provide system solutions for biogas production in the following areas APPLICATIONS anaerobic wastewater treatment plants waste fermentation plants sewage sludge digestion agricultural biogas plants

Request for a quoteResults for

Solutions in - Import exportNumber of results

185 ProductsCountries

- Germany (185)

- Berlin and region (24)

- Bonn, Düsseldorf and North Rhine and Westphalia (30)

- Frankfurt am Main and Hesse (12)

- Hamburg and region (1)

- Hannover and Lower Saxony (1)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (3)

- Mainz and Rheinland-Pfalz (4)

- Munich, Nuremberg and Bavaria (25)

- Saarbrücken and Saarland (2)

- Stuttgart, Freiburg and Baden-Wurtemberg (71)

- Weimar and Thuringia (11)

Company type

Category

- Cleaning and maintenance products, household (24)

- Tanks, metal (24)

- Labelling machines (15)

- Trolleys and trucks (12)

- Lighting, street, industrial and commercial (10)

- Electronic data processing - microcomputers (8)

- Pad printing (5)

- Sensors (5)

- Switching systems (5)

- Cutting - machine tools (4)

- Machine tools, metal machining - parts and accessories (3)

- Packing and packaging - machinery and equipment (2)

- Accumulators and batteries (2)

- Keyboards - computer (2)

- Software (1)

- Automation - systems and equipment (1)

- Laser - cutting and welding machines (1)

- Mechanical engineering - custom work (1)

- Steel & Metal Transformation (1)

- Air conditioning, aeration and ventilation equipment (1)