- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- soldering lasers

Results for

Soldering lasers - Import export

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

NANOSYSTEC GMBH

Germany

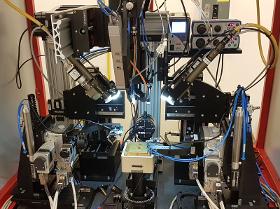

NanoHybrid provides a large degree of versatility. The active alignment, test and assembly station combines various assembly methods including gluing, laser welding or selective laser soldering. In addition, the station offers opto-electronic testing capability. Therefore, NanoHybrid is ideally suited for the development and small serial production in manufacturing companies or in research institutes. In such a product development area, an active alignment station needs to cope with opto-electronic and other precision devices with varying sizes and characteristics.

Request for a quote

NANOSYSTEC GMBH

Germany

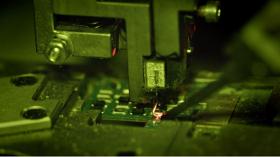

NanoSolder actively aligns optical components such as photonic circuits, waveguides, diode lasers and photodiodes. It uses selective laser soldering for the assembly. Compared to gluing with subsequent curing, much shorter assembly times will be achieved by selective laser soldering.

Request for a quote

NANOSYSTEC GMBH

Germany

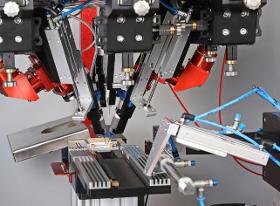

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

NANOSYSTEC GMBH

Germany

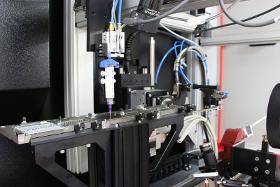

VersaSolder uses selective laser soldering for applications where other methods fail. A laser beam heats an area without impacting the surrounding the key advantage of this non-contact joining technique.A lens assembly focuses the laser power which melts the solder onto the working area. It is tailored exactly to the specific shape of the solder joint and the beam may be circular, elliptic or a straight line. An optional pyrometer measures the temperature in the melt pot and the electronic actively regulates the power profile. Multiple solder heads heat various areas at the same time and a symmetrical arrangement reduces shift. In order to achieve higher productivity, nanosystec developed the Multi Beam Optic (MBO). It generates a number of sub beams processing more than one connection in the same time – up to 40 individual spots have been demonstrated.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HERACLE GMBH

Germany

Our aluminum coated fiber are available for both operating windows in ultraviolett and visible/near infrared wavelength ranges. In addition, heracle offers a solarisation resistant version for ultraviolett region. The fiber features a wide operating temperature range from cryogenic up to 400° C and makes it ideal for Aircraft, missile, rocket, turbine & jet engine monitoring. The aluminum layer offers a hermetic coating. The fiber can be sterialized. Termination can be directly soldered for vacuum feedthroughs & laser diode pigtailing. Its radiation resistancy, low outgassing and resistancy to organic solvents allow for operation in radiation, caustic & corrosive environments.

Request for a quoteResults for

Soldering lasers - Import exportNumber of results

7 ProductsCountries

Company type