- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- smd components

Results for

Smd components - Import export

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

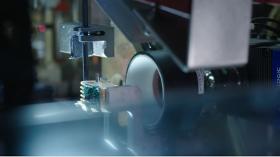

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. For components of the most varied shapes and with diverse electronics components, we will set up our AOI stations according to individual needs and provide reliable optical control of the overall assembly. Automatic optical inspection of your components is naturally part of our service range.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. The 3D automatic optical inspection of SMD components combines 2D and 3D inspection at maximum speed. Some of our machines allow an inspection in 360 ° steps. Depending on the machine, excellent dynamic properties and the highest positioning speed can be achieved on the basis of linear drives.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. So you want to achieve compact shapes for complex components? Our test and programming service is there for you. The system we use keeps line contact high, offers perfect access and ensures precise bonding. The advantages for you: flexible program selection until shortly before the start of production, no extra expenditure for external programming.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. High-performance placement machines by ASM with short setup times and high flexibility form the backbone of our automated SMD placement systems. Our services also include assembly of THR components (pin-in-paste technology). Extensive monitoring systems and built-in cameras ensure high precision in the placement process.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. Printing the soldering paste takes place using the latest soldering paste stencil printers. They are so exact that even the tiniest elements can be precisely placed. The faultless print result is reliably assured with a 3D paste inspection.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. We have the latest generation Rehm reflow soldering systems. In particular with regard to temperature zones, they are exceedingly efficient. The soldering process takes place in a protective atmosphere. In the reflow soldering process, we process through-hole and SMD components. The number of work stages, sources of error and thermal loads is reduced. In the reflow process we are also able to solder through-hole components, thereby reducing sources of error and repeated thermal load and work stages.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution Component supply and emissions over hand-operated turret Application Quality assurance in the electronics industry. Batch testing; Test equipment for testing and optimization of weld two part housings of SMD components. Batch testing; Test device for checking and optimizing the welded connection on two-part housings of SMD components. Test device for small SMD parts Documentation of the maximum torque achieved and the tear-off angle. Documentation of the maximum achieved torque and angle of demolition.

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

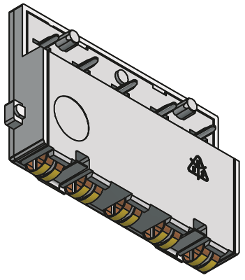

• Universal use with various enclosure types • High current (5 A per bus pcb-rail) • Quick and easy mounting in the DIN-rail • Contour and layout of the bus pcb can be according to customers' requirements e.g. defined by the customer • Designed for standard DIN-rail dimensions • Large stand-off to DIN-rail floor allows the mounting of SMD components on the bus pcb underside • The carrier profile is securely fixed by safety caps (left and right) on the DIN-rail • Pcb rail "breaks" are possible, e.g. for operation of bus signals inside instruments

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

• Universal use with various enclosure types • High current (5 A per pcb-rail) • Quick and easy mounting in the DIN-rail • Contour and layout of the bus pcb can be adapted according to customers' requirements e.g. defined by the customer • Designed for standard DIN-rail dimensions • Optional coding of the bus system to prevent incorrect assembly • Large stand-off to DIN-rail floor allows the mounting of SMD components on the bus pcb underside • The carrier profile is securely fixed by safety caps (left and right) on the DIN-rail • Pcb rail "breaks" are possible, e.g. for operation of bus signals inside instruments

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

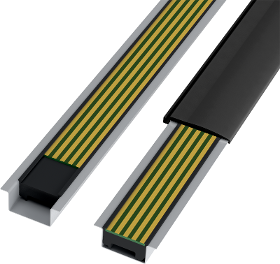

• Universal use with various enclosure types • High current (5 A per power cable) • Quick and easy mounting in the DIN-rail • Contour and layout of the bus pcb can be according to customers' requirements e.g. defined by the customer • Designed for standard DIN-rail dimensions • Large stand-off to DIN-rail floor allows the mounting of SMD components on the bus pcb underside • The carrier profile is securely fixed by safety caps (left and right) on the DIN-rail • Pcb rail "breaks" are possible, e.g. for operation of bus signals inside instruments

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

• According to DIN EN 61810-1, DIN EN 61810-3, DIN EN 45545 (fire protection on railway vehicles) • With forcibly guided contacts • Safe separation betwenn coil/contact and contact/contact for applications at pollution degree 2 with rated insulation voltage 250 V • Clearance and creepage distances contact - coil ≥ 5.5 mm contact - contact ≥ 5.5 mm • Low nominal and holding power • High mechanical service life • Extremly smallest height only 10.3 mm and minimum area • RoHS compliance • Placing SMD components between PCB and relay is possible

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

• According to DIN EN 61810-1, DIN EN 61810-3, DIN EN 45545 (fire protection on railway vehicles) • With forcibly guided contacts • Safe separation betwenn coil/contact and contact/contact for applications at pollution degree 2 with rated insulation voltage 250 V • Clearance and creepage distances contact - coil ≥ 5.5 mm contact - contact ≥ 5.5 mm • Low nominal and holding power • High mechanical service life • Extremly smallest height only 10.3 mm and minimum area • RoHS compliance • Placing SMD components between PCB and relay is possible

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

• According to DIN EN 61810-1, DIN EN 61810-3, DIN EN 45545 (fire protection on railway vehicles) • With forcibly guided contacts • Safe separation betwenn coil/contact and contact/contact for applications at pollution degree 2 with rated insulation voltage 250 V • Clearance and creepage distances contact - coil ≥ 5.5 mm contact - contact ≥ 5.5 mm • Low nominal and holding power • High mechanical service life • Extremly smallest height only 10.3 mm and minimum area • RoHS compliance • Placing SMD components between PCB and relay is possible

Request for a quote

E. DOLD & SÖHNE GMBH & CO. KG

Germany

• Universal use with various enclosure types • High current (5 A per bus pcb-rail) • Quick and easy mounting in the DIN-rail • Contour and layout of the bus pcb can be according to customers' requirements e.g. defined by the customer • Designed for standard DIN-rail dimensions • Large stand-off to DIN-rail floor allows the mounting of SMD components on the bus pcb underside • The carrier profile is securely fixed by safety caps (left and right) on the DIN-rail • Pcb rail "breaks" are possible, e.g. for operation of bus signals inside instruments

Request for a quoteResults for

Smd components - Import exportNumber of results

15 ProductsCountries

Company type