- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- small batch

Results for

Small batch - Import export

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

IGUS® GMBH

Germany

igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations Delivery program: Delivery program: Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60 igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations igus® presents the first tribo filament for 3D printers The new 3D printing materials are up to 50 times more abrasion-resistant than conventional 3D print materials. Complete processing instructions for iglidur® I170-PF (PDF) Complete processing instructions for iglidur® I180-PF (PDF) iglidur® |180-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Excellent wear behaviour Material table Colour white Moisture absorption at 23 °C and 50 %r.h. 0,3 weight-% Max. water absorption 0,9 weight-% Max. long term application temperature +80 °C Max. short term application temperature +90 °C Minimum application temperature -40 °C Delivery program: iglidur® |170-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Outstanding wear behaviour of the tribo filaments Harder to process Material table Colour yellow Moisture absorption at 23 °C and 50 %r.h. 0,5 weight-% Max. water absorption 1,6 weight-% Max. long term application temperature +75 °C Max. short term application temperature +85 °C Minimum application temperature -40 °C Delivery program: Y = rate of wear [µm/km] * moulded Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Y = rate of wear [µm/km] * moulded Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Housing for satellite positioning devices TC designed and constructed a weatherresistant housing in a very small batch for highly sensitive satellite positioning measuring devices. Do you already have an idea of what we could do for you?

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

We are able to produce various shades of high-quality decorative polyester top coats in small and very small batches using a paste system – resulting in a very competitive pricing for our customers.

Request for a quote

HO-MA GMBH

Germany

With vibration sorting, small batches / quantities can be processed individually up to 200 pieces per minute. Depending on the type of object, we recommend different designs / types – conical, cylindrical or stepped. Surfaces are preferably glass bead blasted or metaline coated (both variants have FDA approval). Mounting types are medium voltage and external voltage.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Radome antennae TC is working with the customer to develop suitable solutions for antenna systems. This ranges from small batches all the way up to largescale production, naturally including the necessary mounting and connecting parts such as cover components with cable bushing, brackets for mobile phone masts, etc. The parts are processed on our highprecision 5axis CNC machinery.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Do you need safe and corrosionresistant access systems for your operations? And do these stairs also need to be movable? Then get in touch. We can design and manufacture special solutions as oneoff commissions or small batches, or a standard solution in larger quantities. Made of glass fibrereinforced plastic profiles, our mobile stairs are suitable for using in corrosive environments or for sites where a stairway needs to have an electrically insulating effect.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

The economic adjustment to small batch sizes, we meet with our turned parts for the direct assembly in plastics and die-cast products. Any thread forms such as, thread-tapping (DIN7500), thread cutting (DIN 7513-7516) or KTG for direct screw in plastics are realized cost-effectively. Advantage is the elimination of high tooling costs, since no counter-thread in the workpiece (eg threaded inserts, nuts, etc.) is required because the direct assembly takes place directly into the workpiece. Only a given tube is required in order to screw it directly. Our turned parts replace previously cold formed parts used (so-called multi-station presses) which require high output volumes in order to achieve a reasonable price parts.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

PT screws for thermoplastics: Thread rolling screws for direct screwing into plastics, Thread 30° or 60° KTG screws for thermoplastics: Single-start or double-start thread (high, low) Thread rolling screws are extruded for larger batch sizes and turned for small batch sizes (Turned parts for direct screwing) High tensile and highly stressable connection of thermoplastics with considerably longer life endurance Thread rolling without chips and loss of material Minimum radial tension, large thread coverage Process-reliable due to torsion strength Shorter and slimmer screws are possible. Materials: Steel, case-hardened Quenched and tempered steel 1.5523 tempered to 1000 +200 N/mm², high-grade steel 1.4567, other materials on request Length: 3 – 160 mm (at lengths from 60 mm only partial thread lengths 4 x d are possible) Thread diameter: 1.6 – 10 mm Special dimensions on request Batch sizes: Standard ex-stores Special screws from 30,000 pieces

Request for a quote

DIETZ GMBH

Germany

With laser generation, components are built up layer by layer from powdered metallic materials used in serial production such as 1.2709 steel or 1.4543 steel. Thanks to state-of-the-art technology, this enables us to transfer your computer-generated 3D/CAD models reliably over to their physical form. Here, thin coats of the powder materials are applied to a base object before being melted using a laser into the desired contour. This process is continued on a revolving basis until the workpiece is complete with the final geometric form and the relevant functional properties. Incidentally, we reclaim excess powder material during this process and use all of it for later productions again. Our services in sample development also include technical springs, which we produce in small batches for your sample application. Traditional sample development services are a new addition to our portfolio. Here, we produce a small-scale series of your bent strip parts from original materials.

Request for a quote

DIETZ GMBH

Germany

We can produce the parts you require using specific tools or on special-purpose machines. We produce complex forms and assembly parts with strip thicknesses of 0.10 to 3.00 and with strip widths of up to 100 mm – depending on the material used. The manufacturing processes that we offer include: Punching, forming, embedding, welding, bolting, riveting and mounting. We perform the assembly of small batches by hand, while larger volumes are performed automated if you so wish. Our hybrid sub-assembly production includes the over-moulding of punched parts made of wire or metal with a variety of plastics or silicones. In order to ensure that the desired braking element features optimum properties, we make use of both the temperature durability and the haptic advantages of silicone and the weight advantage of plastic when combining these materials in this fashion. Guide tube assemblies, a combination of springs and tubes, are part of the hybrid component portfolio.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

In the area of elastomer technology, the Zimmer Group uses the most modern production processes to manufacture sophisticated workpieces from elastomers. In addition to the transfer molding process, in which the elastomer is placed in a mold, pressed into shape with a die and vulcanized under pressure and heat, we also use the injection transfer molding process. Here, the starting materials are pressed into the mold on an injection molding machine and vulcanize out there. With these two processes, we process a wide range of elastomers such as NBR, silicone, EPDM, FPM or polyurethane. In terms of quantities as well as dimensions, the sky's the limit, because we can manufacture almost any quantity required, from special solutions in quantities of one to medium-sized small batches and large series of more than 10,000 units.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

We offer LED technologies for existing applications. With our modular concept, combined with our calibration laboratory and in-house production we offer decisive development advantages. POSSIBLE REASONS FOR CUSOMIZED UV-LED: The system already exists. Standard products can’t be installed due to limited space. Irradiation from one direction is not sufficient The determination of irradiation wavelength has not yet taken place You are looking for a competent and independent partner YOUR ADVANTAGES WITH OPSYTEC UV-LED CUSTOMIZED SOLUTION: Development and production from a single source Ideal for small batches, tests and prototypes Wavelength 275 nm, 365 nm, 385 nm, 395 nm and 405 nm available Further wavelengths are possible Suitable sensor? We offer customer-specific solutions, too Reliable results through our own calibration laboratory Special solutions are beneficial - even for small quantities. Ask us!

Request for a quote

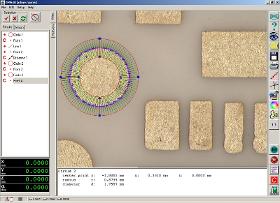

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The flexible, easy-to-learn measuring software for two dimensional measurements of primary samples and small batches by either hand-operated or motorized-operated measuring microscopes, for use in laboratories or production areas. OMS is available in english or german language. measuring in the video image by mouseclick easy manual measuring by mousclick directly in the video image automatic measuring functions intuitively usable tools are available for the automatic edge detection of point, line, circle and circle sector example of a manual measuring function flexible on-screen manual measuring functions scaled overlay masks different scaled overlay masks for direct shape and dimension comparison of products and prototype samples list of already measured elements list of already measured elements for further combinations

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The SV 30 is a small stand mixer with manual stroke adjustment and spring suspended lid for small batches that range in volume from 20 l up to 100 l and agitator drives of up to 1.5 kW. It is supplied with helical gear agitators of up to 0.75 kW or fast running agitators of up to 1.5 kW and the suitable mixing elements. Thanks to the H stand as well as two hook blocks, the SV 30 can be moved. The weight is balanced by means of a counterweight positioned in the stand column itself. The pneumatic supply is guided through a laterally mounted energy chain. Explosion-proof design ATEX 2014/34/EU feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

SV 30 - Small stand mixer The SV 30 is a small stand mixer with manual stroke adjustment and spring suspended lid for small batches that range in volume from 20 l up to 100 l and agitator drives of up to 1.5 kW. It is supplied with helical gear agitators of up to 0.75 kW or fast running agitators of up to 1.5 kW and the suitable mixing elements. Thanks to the H stand as well as two hook blocks, the SV 30 can be moved. The weight is balanced by means of a counterweight positioned in the stand column itself. The pneumatic supply is guided through a laterally mounted energy chain. Explosion-proof design ATEX 2014/34/EU feasible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The semi-automatic labeling machine TNC-R was developed for the all-round labeling of tubes. Small batches can be labeled quickly and precisely with the labeller. The tubes are placed manually in the labeling system. As soon as the 2-hand operation is activated, the automated labeling process starts. The product is rotated and shifted, then the wrap-around label is applied exactly to the product. A printing unit can be integrated for individual labeling of the tubes. You can easily print the labels yourself inline. The integration of a printing unit is suitable, for example, for laboratory tubes or sample vessels that have to be provided with individual data.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This manual labelling solution was developed to apply one or more seal labels to folding boxes in small batches - before fully automatic lines are changed over to the product, the products are already sealed with this device. The seal label can be applied to all closure flaps as required. An ultrasonic fork sensor enables the processing of transparent and non-transparent sealing labels. Label roll-on across corners is clean and accurate. The solution for smaller, decentralized labeling jobs: — suitable for transparent/non-transparent (ultrasonic label sensor) — reliable, handy with handle bar — non-slip stand — easy setup — repeatable application of labels — core diameter: 76 mm — max. outer diameter: 200 mm — max. label width: 80 mm — label winding: outer winding

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The LSS-PV model was developed to serialize small product batches cost-effectively and according to the requirements of country-specific FMD guidelines. The products are fed manually. A transport system with product carriers guarantees a precise and continuously accurate alignment of the products. After the printing process performed by a thermal inkjet printing system (TIJ), the print data is inspected. If the inspection result is positive, the products are either collected on the collection table at the outfeed of the system or glide over an optionally available transfer plate into an outer shipping case. Defective products are reliably separated from the GOOD products by the product reject station. This process is verified twice in the PLC.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory vacuum shovel dryer DRUVATHERM® is a system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production too. The Lödige laboratory vacuum shovel dryer DRUVATHERM® is a horizontal, batch vacuum dryer with a frequency-controlled mixing tool. This mixer consisting of mixing elements adapted to the process and arranged on a shaft according to a specific system - is installed in a cylindrical mixing drum equipped with a temperature control jacket. Rotation of the mixing unit generates a three-dimensional product movement, in which all of the product is constantly in motion. The contact frequency of particles with the heat exchange surface leads to shorter drying times. The chopper rotating at high speeds fitted to the side of the mixing drum is used to disperse the product . This leads to a significant increase in drying capacity and prevents moisture and temperature gradients.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Powder systems with robots can be effectively used even for small batches. In addition to the classic method of powder coating using manual spray guns or masts, the demand for robot systems has risen sharply. Rippert offers the entire spectrum here too. Both powder-coating systems with robots and wet painting systems are supplied with intelligent software solutions. This also allows the economical processing of small lot sizes. Automatable high-speed paint changing systems have also been available for some time. Rippert plays a leading role in automated powder-coating systems with industrial robots.

Request for a quote

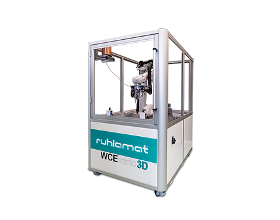

RUHLAMAT GMBH

Germany

Based on a single station concept with compact design and user-friendly handling, the WCEvario3D is ideal for wire laying on flat and uneven surfaces as well as for producing and processing prototypes and small batches. With a wide range of additional options that may be integrated, the system can be profoundly expanded. For safe and accurate handling of complex components, the workpiece is attached to a product-specific fixture. With constant pressure-force control, a flexible wire-laying unit is able to precisely follow convex and concave shapes. Parameters such as size and shape can easily be adapted to the respective tasks. Our comprehensive expertise in sonotrode technology for various substrate-wire combinations ensures the highest precision in wire embedding. Different versions for different requirements Basic System With the basic version shown on the right, which uses ultrasonic wire-embedding technology, heatable wires can be embedded with the highest precision and...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series V 630 - 1600 TC The classical HEINKEL top discharge centrifuges are a cost-effective alternative in chemical manufacturing. The centrifuge can be easily adapted to the product characteristics and is therefore suitable for companies that manufacture a variety of products in small to large batches. Special properties for the benefit of the customer: Flexible adaptation for difficult to filter products Lossless filter cake discharge Gentle solids discharge without particle destruction Excellent washing and extraction effect Simple centrifuge design Reliable system for removal of the filter bag Rugged and simple system for the detachable border ring

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series V 630 - 1600 TP The classical HEINKEL top discharge centrifuges are a cost-effective alternative in the pharmaceutical production. The centrifuge can be easily adapted to the product characteristics and it is therefore suitable for companies that manufacture a variety of products in small to large batches. Special properties for the customer´s benefit: Flexible adaptation for difficult to filter products Lossless filter cake discharge Gentle solids discharge without particle destruction Automatic CIP cleaning Easy accessibility of all machinery parts in contact with the product Excellent washing and extraction effect Simple centrifuge design

Request for a quote

KLN ULTRASCHALL AG

Germany

In our laboratory we have all options to supply you with tests, parts analysis and pre- or small batches productions. Our team of highly skilled experts will assist you, if you have any question about how to design your parts for optimal welding. In our plant in Heppenheim we have the option to do welding tests with all the welding methods we offer in order to give you the maximum reliability for your serial process.

Request for a quote

SIM AUTOMATION GMBH

Germany

Entire system solution from a single source: — from construction of the laser cell to integration of your chosen KEYENCE laser — self-contained and high-performance solutions for laser labeling small batches of individual parts Equipment variants SIM-Marker Classic: Basic — mechanical Z-axis, manual adjustment of the focal point with adjusting wheel — manual opening and closing of the lift door by hand, after safety release Advanced — electric Z-axis, adjustment of the focal point with operating button — Opening and closing of the lift door with operating button — Set up: directly on a desk or mounted onto the movable base frame Advantages of integrated optical three-axis technology: — focal point to be freely set and is especially impressive — mark on any shape with outstanding sharpness, including on slanted surfaces, cylinders and cones Size of the labeling field: between 120 x 120 mm and 330 x 330 mm.

Request for a quote

SIM AUTOMATION GMBH

Germany

Entire system solution from a single source: — from construction of the laser cell to integration of your chosen KEYENCE laser — self-contained and high-performance solutions for laser labeling small batches of individual parts Additional possibilities with the SIM-Marker Plus: — Focal point height adjustable within a range of 42 mm (±21 mm) — Autofocus with 3-axis laser control (simultaneous control of the X, Y and Z axes of the laser optics) — Distortion-free marking of 3D objects such as bevels, cylinders, spheres and cones — Set up: directly on a desk or mounted onto the movable base frame — Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: — focal point to be freely set and is especially impressive Size of the labeling field: between 120 x 120 mm and 330 x 330 mm.

Request for a quote

SIM AUTOMATION GMBH

Germany

Entire system solution from a single source: — from construction of the laser cell to integration of your chosen KEYENCE laser — self-contained and high-performance solutions for laser labeling small batches of individual parts SIM-Marker Mini Equipment options: Standard version — Manual setting of the focal point with mechanical lift table — Door opening by hand — Connection to PC via LAN or USB — Set up: directly on a desk or mounted onto the movable base frame — Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: — focal point to be freely set and is especially impressive — mark on any shape with outstanding sharpness, including on slanted surfaces, cylinders and cones Size of the labeling field: between 120 x 120 mm and 330 x 330 mm.

Request for a quoteResults for

Small batch - Import exportNumber of results

50 ProductsCountries

Company type

Category

- Automation - systems and equipment (7)

- Machine tools - metal machining (6)

- Screws (3)

- Pharmaceutical industry - machinery and equipment (2)

- Labelling machines (2)

- SMALL METAL PARTS (2)

- Measurement and control instruments (1)

- Adjustment - machine tools (1)

- Automation - advisory services (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Conveyor systems (1)

- Grinding - steels and metals (1)

- Joints, pneumatic (1)

- Laboratory equipment and instruments (1)

- Measurement - Equipment & Instruments (1)

- Milling - machine tools (1)

- Pad printing (1)

- Plastics - industrial machinery and equipment (1)