- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sleeve processing

Results for

Sleeve processing - Import export

SPANSET SECUTEX GMBH

Germany

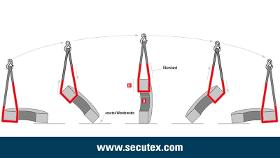

secutex protective sleeves are vital when turning over coils. The lifting strap is attached to a crane hook and attached to the load with the secutex protective sleeve. During lifting, the strap moves freely through the protective sleeve while the latter remains motionless against the load. This means that turning the load 90° is possible without any problem whatsoever. If the load is paced to the other side according to the same principle, it can be also be turned by 180°. The lifting strap can slide through the protective sleeve during the turning process. The protective sleeve and load, however, remain in constant contact. Our tips for safe turning – The lifting strap is exactly at „12 o‘clock“ over the centre of the coil. – Only individual, unpackaged and cleanlywrapped coils may be turned. – A nonslip surface, such as the secutex turning mat (cf.p. 102] must be used. – The coil must be prevented from rolling in or sliding perpendicularly to the lifting strap.

Request for a quote

PRESSTECK S.P.A.

Germany

Thermostatic valves - i.e. the temperature controls on the heating system - are found in just about every home. In the head of a thermostatic valve there is a metal bellows, a corrugated tube that expands according to the room air temperature. For these metal bellows, the manufacturer needed deep-drawn, very long and thin-walled sleeves. The challenge: the sleeves must be matched to the customer's downstream process under very tight tolerance specifications. Why? Because the sleeves cannot be further processed if the geometries vary. Absolute precision is therefore required. We can offer absolute precision. The customer commissioned us with the production of the sleeves. On the one hand, because we fulfil the special deep-drawing requirements. On the other hand, because we can offer an associated, targeted heat treatment for material stress relief in-house.

Request for a quote

DSMART GMBH

Germany

Production Process of shrink sleeve labels A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Slitting or folding F: Shrink sleeve making/cutting G: Final inspection H: Delivery Other information of shrink sleeve labels A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quote

MERA BELLOWS C/O ANSCHÜTZ VERWALTUNGS GMBH

Germany

Deep-drawn tubes from stainless steels (with a closed side or open) Deep-drawn tubes from non-ferrous metals as bronze, brass,... Seamless sleeves made with stamping processes Ultra thin-walled tubing in Beryllium copper or other special alloys Annealing services in vacuum furnaces Washing technologies for soap and oil The precision tubing is needed at Mera Bellows to manufacture seamless metal bellows.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sleeve processing - Import exportNumber of results

4 ProductsCountries

Company type