- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shredded

Results for

Shredded - Import export

WHITE STEEL GMBH

Germany

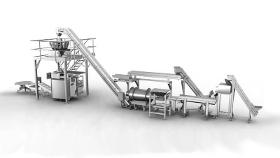

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Cheese chopping machine SCADA and HMI with a touch screen system Hardened stainless steel slicer and 3d chopping system Cups feeder system Antistick powder processing system Vertical conveyor transfer system Automatic suppress distribution system Electro pneumatic weighing cells 3 levels weighing cells Weighing tower Packaging machine Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

ERDWICH hammer mills are the answer to the challenge of selectively shredding hard and brittle materials. Then again, ERDWICH hammer mills also take the pelletisation of rubbery materials – as preparation for downstream separation systems – in their stride. A tough customer? Just so. ERDWICH hammer mills are especially suited to metal, electrical and electronic scrap or swarf from steel or aluminium – and many other materials besides. Simple adjustability during operation also makes short work of the pelletisation of non-ferrous metals. The final fragment size is variable and can be changed during operation. That’s also a great example of the product’s flexibility in catering to a wide range of applications. For the selective challenges in life. ERDWICH hammer mills.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

When processing electronic scrap, the aim is not merely to ensure the highest levels of process reliability and performance, but to salvage components such as capacitors and batteries intact where possible. Here, the the RM 1350/2 coarse shredder really struts its stuff: with the especially slow-running twin-shaft rotor/shredder system, the machine is especially resource-friendly and so ensures a large quota of intact capacitors and batteries. Two sizes of machine, with different shredder lengths and drive specifications are available to meet any challenge.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Reducing transportation costs, compressing material for feeding to existing pressed-waste containers or baling presses, or shredding of material for conveyor belt feeding are good reasons for deploying a cardboard shredder. With the EKZ cardboard shredder and FKZ paperboard shredder, ERDWICH’s two rugged machines offer 100% process reliability in a range of form factors. Whether you need to shred packaging or process cardboard waste for feeding into existing conveyor systems, ERDWICH can always offer you a perfect solution tailored to your requirements.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The uniform shredding of coarse materials: that’s the speciality of the ERDWICH three-shaft shredder. ERDWICH has created the three-shaft design especially for these requirements. Entirely free of clogging and jamming – even with solid materials. Clever, huh? Absolutely: after all, the three cutter shafts and their individual sets of blades rotate at different speeds, so as to continuously pull in and precisely shred the feedstock material. If the material is too large, the sweeper shaft simply transfers the material to the lower cutter shafts for further size reduction. Again and again – until the material is the exact size as specified. Tirelessly, and with perfect reliability. Fragment size selection itself is achieved by the perforated screen substructure through which the material exits after the shredding process. Precise shredding of large and solid materials. That’s what ERDWICH does.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Achieving precision material breakdown in just a single operation: that’s the proven capability of the Erdwich single-shaft shredder. How does it do it? The material is taken up by the cutting rotor and shredded repeatedly against the stator blade, using the tried-and-tested rotor/stator principle. This continues until the desired size has been achieved and the material can pass through the perforated screen underneath. The result is impressive: superior efficiency and optimum reliability for predefined fragment sizes. Choose the mature and highly economical technology of the ERDWICH single-shaft shredder for your application.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor: This means your expensive machine tool cannot attain its full productive potential. The key challenge here is therefore: PROCESS RELIABILITY But there is another way. In fact, there are several proven solutions – centralised and decentralised – to this problem. ERDWICH machines and plant for swarf shredding and processing offer the highest levels of economic viability, safety and efficiency. With the decentralised solution, the ERDWICH swarf breaker is set up directly next to the lathe or machining centre. The swarf is removed and transported away to a central processing point either manually using a swarf cart or by means of pneumatic extraction, pumping or some other conveyor system. With the centralised solution, the swarf is collected in swarf carts at each machining centre and then transported to the ERDWICH master processing plant. This...

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Shredded bark is burned as fuel to generate energy. It is indispensable to supply uniform particle sizes to energy plants. The degree of preparation is determined by the shape and arrangement of the beaters and size reduction elements as well as the rotor speed Key features Shredded bark is fed to shredder from above Rotor with vertical shaft and equipped with oscillating beaters Inside wall of lower housing equipped with size reduction elements and wear plates Gravity discharge of shredded material to below Easy access to lower part of housing for maintenance Advantages Suitable for almost all types bark High operational safety No risk of clogging, even with longer or wet bark pieces Insensitive to foreign matter of any kind Optimally adaptable to any feed material Maintenance friendly High throughput capacity Low energy requirement

Request for a quoteResults for

Shredded - Import exportNumber of results

9 ProductsCountries

Company type