- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- series

Results for

Series - Import export

ALPHA LASER GMBH

Germany

The laser welding systems of the AL series can be used universally. They might be integrated into existing machine structures or used with an application device for manual welding. In combination with our NC-controlled laser machining table AL-T you get a real professional solution. We offer the required performance class for every application. You can choose between 75 and 900 W. There is a wide range of processing lenses and equipment options for these laser systems. Regardless of whether you use a simple 90 ° deflection lens, the tilt-swivel lens or our circular welding lens - the laser beam always reaches the desired point on the workpiece with pinpoint accuracy. Additional equipment options are optionally available for the AL, such as: • Micro welding device for a welding spot diameter <100 µm • Rotary axis module for cylindrical welds • automatic wire feeder • Workpiece holder • camera system •…and much more

Request for a quote

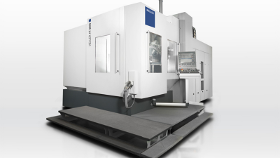

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

4-axis horizontal machining centres for highly productive machining in all disciplines Tailor-made off the peg for you: modular machine series offering unbeatable productivity at unique load capacity. Highlights Unrivalled long tool life, reduced energy consumption and costs due to realistic dynamic rates High performance and precision from light-metal machining through to heavy-duty machining For varying batch sizes and a variable range of parts and materials HighSpeed Cutting, heavy cutting, dry or MQL machining at full productivity Advantages Fully customisable to your requirements in terms of spindle, spindle taper, tool magazine and chip disposal Attractive price/performance ratio Highest load capacity and reliability High availability thanks to sophisticated safety concept and HELLER services

Request for a quote

IGUS® GMBH

Germany

Overview of E4.1 benefits Additional information Series E4.21 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm E-Chain® with crossbars at every link Series E4.28 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series E4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series E4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series E4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series E4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every link Series 1640 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.112 series Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.162 series Inner height hi: 162 mm Inner widths Bi: 200 - 600 mm bending radii R: 250 - 1000 mm Pitch: 200 mm E-Chain® with crossbars at every link Series 800 Inner height hi: 200 mm Inner widths Bi: 200 - 600 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series 840 Inner height hi: 204 mm Inner widths Bi: 100 - 563 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series E4.350 Inner height hi: 350 mm Inner widths Bi: 400 - 800 mm bending radii R: 500 - 1000 mm Pitch: 470 mm E-Chain® with crossbars at every link Series H4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series H4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series H4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series H4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every other link Series H4.112 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R4.28 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R4.56 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R4.80 Inner height hi: 80 mm Inner widths Bi: 150 - 460 mm bending radii R: 200 - 1000 mm Pitch: 111 mm E-Tube, swivel lid Series R1608 Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 600 mm Pitch: 143 mm E-Tube, swivel lid R4.112 series Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA classification -Report IG 1303-640, tested E4.32.10.063.0 41 dB(A) determined at the igus® laboratory, v = 1.8 m/s unsupported ESD classification: Electrically conductive ESD/Atex versions on request System E4.1 proven in long travels e-tubes available as special design with HT material for 850°C hot chips Overview of E4.1 benefits Additional information Series E4.21 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm E-Chain® with crossbars at every link Series E4.28 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series E4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series E4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series E4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series E4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every link Series 1640 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.112 series Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.162 series Inner height hi: 162 mm Inner widths Bi: 200 - 600 mm bending radii R: 250 - 1000 mm Pitch: 200 mm E-Chain® with crossbars at every link Series 800 Inner height hi: 200 mm Inner widths Bi: 200 - 600 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series 840 Inner height hi: 204 mm Inner widths Bi: 100 - 563 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series E4.350 Inner height hi: 350 mm Inner widths Bi: 400 - 800 mm bending radii R: 500 - 1000 mm Pitch: 470 mm E-Chain® with crossbars at every link Series H4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series H4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series H4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series H4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every other link Series H4.112 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R4.28 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R4.56 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R4.80 Inner height hi: 80 mm Inner widths Bi: 150 - 460 mm bending radii R: 200 - 1000 mm Pitch: 111 mm E-Tube, swivel lid Series R1608 Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 600 mm Pitch: 143 mm E-Tube, swivel lid R4.112 series Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA Classification Report IG 1303-640, tested series E4.32.10.063.0 E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Assembly instruction video Assembly video with accurate description for joining, splitting and opening e-chains® and e-tubes. Installation instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E 4.1 E4.1-E-Chain® with 4-piece structure Smooth, cable friendly inner surfaces Low noise operation through integrated "brake" on the radial stop dogs Sound dampers as an additional noise-reducing option Wide application range Numerous interior separation options Large accessory kits Widths up to 2000 mm through extension links To open on both sides Max. travel distance: Over 200 m Typical industrial sectors and applications: Krane Indoor Cranes Composting systems Sewage treatment plants Machine tools General mechanical engineering Materials-Handling Technology Refrigeration engineering Construction machinery Wood working Robotics and handling systems IPA classification -Report IG 1303-640, tested E4.32.10.063.0 41 dB(A) determined at the igus® laboratory, v = 1.8 m/s unsupported ESD classification: Electrically conductive ESD/Atex versions on request System E4.1 proven in long travels e-tubes available as special design with HT material for 850°C hot chips

Request for a quote

GSW SCHWABE AG

Germany

electric compact control with one or two 10l pressure tanks pressurized dispensation made especially for high viscosity lubricants pulsedependent flow control (0 – 99 pulses/min) dispensation time and delay after the incoming signal electrically adjustable via initiator

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The AQUACHEM LCM 320 (pocket press membrane) is ideal for mobile deployment on site on a suitable trolley and can be operated with up to 15 bar loading and 15 bar membrane squeezing. This machine can also be used as a testing filter press in the case in order to decide on the right fabric or to check the filterability of the suspension. Fully equipped, this compact press can manually implement functions that our fully automatic machines can do. The AQUACHEM LC 320 (pocket press chamber) is identical in design to the LCM 320 and differs only in its function as a chamber filter press (without membrane). The LC 470 is the more affordable, low-cost version of the EC-series. Main feature is the restriction of the feeding pressure to 7 bar. All other features are the same as the EC-series. This series is built in a compact design with a feeding pump and discharge manifold.

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

In the tried-and-tested, gasketed design, the EC-series offers many benefits to the user on top of its ease of operation. Due to the internal drainage, use in even the most hygienically clean areas is possible. The press lock is performed by an automatically self-regulating pneumatic/hydraulic closing system. The automatic closing pressure maintenance ensures that the plate pack always remains closed. An adjustable pressure switch with a potential-free contact is provided for integration into the customer's control system. This prevents the feeding pump from running uncontrollably. Also, as with all AQUACHEM filter presses, the discharge manifold can be generated here at the customer's request. Due to the gasketed design, the seamless backflushing of the filter media in the filter press is possible. The filter press frame is phosphated and powder-coated, offering a high level of protection against external influences.

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The BC-series impresses with its simple and robust technology, while at the same time offering the user many features to simplify work. The optionally available semi-automatic plate shifting allows the user to shift the filter elements conveniently. The hydraulics are controlled via the HMI control system with touchscreen. This allows any feeding pump of your choosing to be integrated and controlled. There are plates available in the formats 800, 1,000 and 1,200 mm, allowing for filtration surfaces of up to 178 m². Thanks to the gasketed design, a clean environment is ensured, even during the internal flushing of the filter elements with aggressive media. The individual discharge manifold enables many functions such as displacement air drying, turbid flow, clear flow, flushing and also cake washing. The standardised hydraulic unit is used in both the BC-series and the AF-series.

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The AF filter presses from AQUACHEM are a further development of conventional chamber filter presses, which have been tried and tested in the industry for over a century. However, due to the degree of automation required and the increase in efficiency necessary nowadays, the technology we have had up until now is often no longer up to date. The design of the AF filter presses is based on the optimum interplay of the ?? individual assemblies of the filter press to ensure reliable, efficient and permanent operation without personnel being present. The automated flexibility of the product enables autonomous adjustment to changing conditions, such as concentration or even specific filter properties. We guarantee these properties and also availability. This is only possible because AQUACHEM and the AF-series possess the knowledge, an intelligent control system and the technology for maximum flexibility. Yes, this is a product with unique selling points – test it out yourself.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

We are specialized in the production of precision parts and assemblies for the medical technology, automotive, telecommunications, metrology and renewable energy industries. We use our own equipment and technologies and undertake in-house fixture construction. Laser machining, electrochemical metalworking and mechanical manufacturing are our core competencies. We manufacture quantities from 50,000 up to several million per year. You will find further information in brochure at our homepage.

Request for a quote

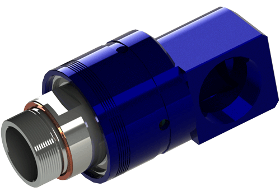

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal use ballbearings (can be relubricated) robust and less influence of dirty media self supportingno additional support necessary housing aluminium, brass or stainless steel rotor stainless steel PRESSURE MAXIMUM vacuum 0 bar DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") air 10 bar DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") hydraulic oil 40 bar DN 50 (2") 50 bar DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") TEMPERATURE MAXIMUM 120 °C air hydraulic oil vacuum SPEED MAXIMUM 750 1/min DN 50 (2") 2500 1/min DN 32 (1 1/4") DN 40 (1 1/2") 3000 1/min DN 25 (1") 3500 1/min DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") SIZEDN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2")

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The MP Linescanner Series from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field-of-view and up to 200:1 optics, each spot on the target surface is capable of being sampled up to three times, ensuring an accurate temperature reading. Each linescanner also includes a built-in line laser for rapid

Request for a quote

GSW SCHWABE AG

Germany

This small yet complete system with reservoir, controls, valve and tubing as well as all other necessary components can be very easily installed and is quickly set to use – even for 3 mm strip thickness

Request for a quote

GSW SCHWABE AG

Germany

manual control with 3l or 10l reservoir made for low viscosity lubricants mechanical locking valve with manifold optional electropneumatic locking valve

Request for a quote

GSW SCHWABE AG

Germany

ideally suited for large coil widths and thicknesses dual arbors for minimal deflection hydraulic wedge type expansion systems highestquality Reel Arbor with maintenancefree bearing and minimal deflection integrated hydraulically powered coil loading system for narrower coils even onesided use possible coil reels as seperate movable components proven support of large rollforming applications especially for the manufacture of welded tubes SHZR Series with variable speed drives via threephase motors and frequency inverter

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Large selection of manual directional control valves with different actuating elements. With lever at 90° / 45° or on the front. With adapter system for mushroom buttons, push buttons or rotary switches. Available in sizes 1/8 and 1/4 to 3/2, 5/2 and 5/3.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIC - KLAUS CZERWONKA

Germany

A classic. The VI series valves comply with the specifications of ISO 5599/1 in sizes ISO 1 and ISO 2 with various configurations and base plates.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Our 15 mm valve series type VA. Valves controlled electrically and pneumatically, completely in aluminium. Available as a single valve or on modular manifolds for maximum flexibility. Core items: Reduced dimensions (15mm) Low power consumption (1 W) Modern design and compactness, for easy installation. Insensitive to pollution. Solid metal construction to ensure long runtime even in demanding environments Flexibility: The valve can be easily wall mounted, manifold mounted and multipolar connection units 3 different connection types LED display manual override Connection strips with exclusive modular system

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The CQ series cylinders are manufactured according to ISO 15552 and have diameters between 160 and 250 mm. Standard version in single / double-acting, with magnetic piston and adjustable cushioning. A complete range of accessories for mounting and position sensing is available.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The CZ series cylinders are manufactured according to ISO 15552 and have diameters between 32 and 125 mm. Standard version in single / double-acting, with magnetic piston and adjustable cushioning. A complete range of accessories for mounting and position sensing is available. Also available in a special version, as a tandem cylinder or with Viton seals for high temperatures. Version with weight-optimized lightweight profile tube including practical slot for position sensors.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The CY series cylinders are manufactured according to ISO 15552 and have diameters between 32 and 125 mm. Standard version in single / double-acting, with magnetic piston and adjustable cushioning. A complete range of accessories for mounting and position sensing is available. Also available in a special version, as a tandem cylinder or with Viton seals for high temperatures. Version with robust and aesthetic profile tube.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Diameter 32-63mm. Standard version in single / double-acting, with magnetic piston and adjustable cushioning. A complete range of accessories for mounting and position sensing is available.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Series of cylinders entirely in stainless steel. Ideal for applications in the food industry and aggressive environments. Available in three sizes 16-20-25 mm.

Request for a quote

BIZERBA SE & CO. KG

Germany

The dynamic in-motion scales of the CWL series are specifically designed for the requirements in the logistics industry. Even in case of high speeds or high loads the verifiable checkweighers or catchweighers provide accurate weighing results. Design your individual solution with the variety of models and options. The CWL-L can be easily integrated in your intralogistic conveyor system, e.g. sorting application, infeed line or parcel shipping system. Efficiently configured and parameterized by means of the provided Bizerba software configuration tool it impresses as a catchweigher with its fast and exact weight determination ‒ even at high speeds of up to 3.1 m/s.

Request for a quote

BIZERBA SE & CO. KG

Germany

Optimize quality assurance of packaged goods with the CWFmaxx checkweigher series CWFmaxx checkweighers are mainly used in food processing companies which have to meticulously clean their systems. The stainless steel housing is suitable for use in hygienic environments. All components are easy to access, so that they can be thoroughly cleaned. The shape is designed to prevent the accumulation of dirt. The CWFmaxx controls the package flow by categorizing and sorting goods via freely definable or legally stipulated weight classes.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Improve process control with wide choice of spectral ranges and focus distances designed specifically for your application Reduce setup time with plug-and-play technology and integrated laser sighting Protect your process and employees with intrinsically safe ATEX/IECEx/CCC-IS certification Choose from options of analogue and digital communication protocols Designed for harsh environments, Thermalert 4.0 Series Pyrometers provide accurate, real-time temperature measurements for process control applications spanning metals, plastics, glass, oil and gas, food and more. This robust solution comes in a compact, integrated package that is easy to install and operate, so you can take your process control to the next level.The Thermalert 4.0 Series Pyrometers from Fluke Process Instruments include numerous integrated infrared temperature sensors with our widest selection of spectral ranges that can be used for a wide variety of process control applications.

Request for a quote

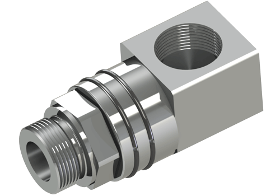

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1")

Request for a quote

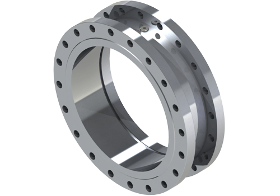

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed short length SIZEDN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") DN 350 DN 400 DN 500 DN 600 DN 700 DN 800

Request for a quoteResults for

Series - Import exportNumber of results

155 ProductsCountries

- Germany (155)

- Berlin and region (2)

- Bonn, Düsseldorf and North Rhine and Westphalia (25)

- Frankfurt am Main and Hesse (49)

- Hannover and Lower Saxony (3)

- Leipzig and Saxony (12)

- Munich, Nuremberg and Bavaria (22)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (40)

- Weimar and Thuringia (1)

Company type

Category

- Electric motors and parts (20)

- Machine tools, metal machining - parts and accessories (10)

- Cylinders, pneumatic (9)

- Hydraulic tools (7)

- Metal straightening machines (7)

- Lifting equipment (6)

- Metals - Machines & Equipment (6)

- Sawing machine tools (6)

- Filtering equipment and supplies (5)

- Mechanical engineering - custom work (4)

- Bearings - ball, needle and roller (3)

- Cameras, cinematographic (3)

- Laser - cutting and welding machines (3)

- Machine tools, metal shaping - parts and accessories (3)

- Terminals, computer (3)

- Compressed air tools and systems (2)

- Infrared tubes (2)

- Internal transport systems (2)

- Magnetic equipment (2)

- Measurement and control instruments (2)