- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- semi-automated labelling machines

Results for

Semi-automated labelling machines - Import export

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

For precise labelling, products with an accessible cavity are manually placed on a format mandrel. By actuating the foot switch or the optionally available 2-hand control, the labelling process is triggered, the product is rotated, and the label is applied precisely to the circumference of the product. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Optionally, the labels can be aligned using a welding seam or other product features (such as opening tabs or lid recesses for tubes). A pneumatic ejection makes the removal process superfluous and blows the well labelled products into a collection box

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The TNC-DS series is used to label cylindrical products on the circumference. For this purpose, the product is manually placed in the product turning station. The labelling process is triggered by actuating the foot switch or the optionally available 2-hand control. The product is rotated, and the label is applied precisely to the circumference of the label. As standard, the model is available with different roll widths (100 to 300 mm) and different label applicators (60 to 250 mm wide) or print- and apply systems. Optionally, the labels can be aligned using a welding seam or other product features. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Depending on the operator, the output of this model is between 10 and 15 products/min.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

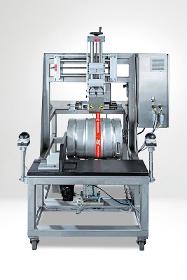

The TNC-GG model series was developed to apply one or more labels to large cylindrical containers at the circumference. Instead of using „die-cut“ labels, it is also possible to handle continuous label material from the roll. Depending on the size of the product, the material is cut inside the system. The largest area of application for these systems is in the beverage industry, where beverage barrels (KEGs) are provided with a deposit banderol on the circumference and thus clearly indicate the owner of the returnable containers. Highly permanent label material is used for these applications, which can no longer be removed from the product without leaving residues. We also offer fully automated solutions for this.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Thanks to the TNC-F model series, semi-automatic labelling of shaped bottles becomes very easy. The front and back labels should be on a carrier material. The product is inserted into a product pickup device. As soon as the 2-hand operation is activated, the system starts to pick up the product in the two format pucks, rotates and aligns the product before the front and back labels are applied exactly to the desired positions. By exchanging the format parts of the product pick-up device, cylindrical or angular products can also be processed and labelled with several labels in addition to the shaped bottles.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

With the TNC-L model series, cardboard boxes and small cartons are provided with sealing or closure labels. The system can be infinitely adjusted to different formats. We determine the format range together with the customer. Optionally, labelling can also take place at several points - for this purpose, the product must be relocated in the system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HERMA GMBH

Germany

Benefits of the HERMA 414 at a glance: Semi-automatic top labeling designed for a wide variety of formats on both flat and curved surfaces. For label dimensions of up to 100 mm in length and 160 mm in width. The heart of the system is the powerful HERMA 500. Entire machine is controlled by the HERMA 500’s basic drive unit. All necessary parameters can be conveniently set on the integrated operator display. Can be adjusted to different product diameters in no time at all. No control box or PLC required.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quoteResults for

Semi-automated labelling machines - Import exportNumber of results

8 ProductsCompany type

Category