- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screw system

Results for

Screw system - Import export

ROLLON GMBH

Germany

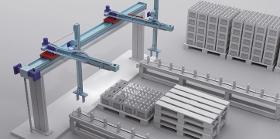

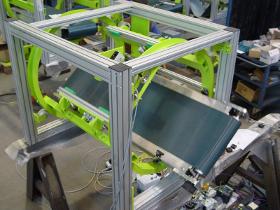

Multiple X/Y/Z Cartesian systems with belt, rack and pinion, screw, and hybrid handling. Utilizing the modularity offered by the full range of our linear actuators (Actuator Line), highly customizable Cartesian systems are available to meet the specific needs of our customers. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Modline linear modules are toothed belt or ball screw driven systems with high accuracy, speeds and load performances. Our experience in the fields of the automotive plants, painting, plate working, manufacturing machines and palletization systems has allowed us to widen our product range with the most advanced technical solutions. Our products stand out for their: high quality and competitive performances; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; no play transmissions achieved by high torque couplings; beams with transversal stiffening ribs and preset for threads on profile ends; accurate scaling and consequent reduced maintenance; fast and accurate belt or without play screw drives; the most complete range of accessories. The Modline linear module strong points are: toothed belt or ball screw driven linear modules; rolling on trapezoidal or recirculating ball guides; payloads from 3 to 2000 Kg; up to...

Request for a quote

ROLLON GMBH

Germany

The PRECISION SYSTEM series of linear units are self-sustaining profile systems made of extruded aluminum and steel for the TK series, able to ensure excellent precision. The motion is achieved by means of precision rolled recirculating ball screws with preloaded or non preloaded ball nuts, depending on the models. Using the recirculating ball bearing technology for the screws and the rails ensures great performance to the linear actuators, such as: High precision and high axial forces High mechanical performance Low wear and tear Low resistance to movement High speed (for long pitch screws) The Precision System series consists of 4 distinct products with different features: TH, TT, TV, TK. PRECISION SYSTEM - TH TH linear actuators are rigid and compact, ball screw driven linear units, enabling high positioning accuracy and repeatability in all process phases with optimal performance assured, with a repeatability within 5 µm. Thrust force transmission is achieved by means of...

Request for a quote

ELKON GMBH

Germany

ELKON Bag Cement Feeding System consists of cement feeding bunker, intermediary cement feeding screw and control panel. The operator puts the cement bag into the cement feeding hopper and tears it by means of the cutters on the hopper. Then the cement is transferred to the cement silo by cement screw. This system can be used to feed 1 unit of cement silos as well as 2 units of silo by using distribution valve.

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

The genius tool for quick installation of bolt screws with power driver Quickest installation through new put - on system. Suitable to screw in and out Simply put on the screw - turn - and take off We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

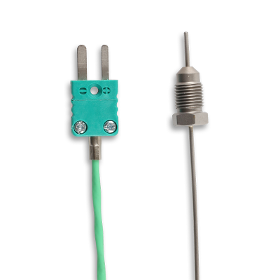

The braking fluid thermocouple from Therma convinces not only with its compact construction but also with its simple installation. Just screw it in in-place of the air vent screw to measure the temperature of the brake fluid. The subsequent sheathing line can then be comfortably bent in the required direction. When the thermocouple is screwed in, the braking system is then vented through its thread. The temperature measurement of the brake fluid, along with the brake disc surface measurement, also supplies important control values for a successful and safe race. During long races or races with many downhill routes, the brake disc overheats over-proportionally. The accruing radiation heat during this has a direct effect on the brake fluid, respectively heats it up. Depending on the type of brake fluid being used, it already reaches its boiling point at approx. 140–260 °C.

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Ideal for crumbly and porous building materials • All-purpose character: also holds in mixed masonry, as is often the case in old buildings • Spreads in several directions and thus ensures secure anchoring and high holding values • Extra deep seating in masonry • Extending rotors prevent rotation in the drill hole • 100% nylon • Altbaujoker + screw: perfectly matched system Description & Area of Application • Multiple spreading by means of 2-way separated spreading elements offset by 90° • Movable rotors • Flexible wall plug neck • Large anchoring depth • Altbaujoker + Screw: Screw with TX drive

Request for a quotePWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application The internal transport of residuals and recyclable fractions, e.g. sievings, screenings and material from grit chambers in waste water treatment plants, as well as various media within production processes, is effected for many years now by belt, spiral and screw conveyors. These systems have proven as very reliable and versatile. As a “connecting element” the PWL GmbH & Co. Anlagentechnik KG supplies the optimal suitable conveyor technology for your specific application. We recommend the encapsulated design of spiral conveyors for process and waste water technology. The spiral conveyors impress with their compact design, the robustness towards clogging and the option to be equipped as a spiral press for simultaneaous dewatering of the conveyed material.

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you suitable systems for filling and/or emptying tank trucks - both for dry bulk materials and for liquids. For this purpose, screw conveyors, pneumatic conveying systems or pumps are for instance used. We consider your individual requirements and build customised tank filling systems and tank emptying systems for you. We develop holistic solutions that are tailored to your requirements and can be integrated into the control of your production process with the appropriate sensor technology. This enables optimum functionality and operating safety.

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Large container / handling stations (tubs) are semi-automatic system components for separating, filling, sealing and capping tubs and canisters and can be used individually or in combination. This enables the precise and modular realisation of your specific tasks on the basis of tried and tested stations. Container separating stations Filling positions with filling valve(s) or manual filling stations Sealing stations with head space gassing or evacuation Capping and screwing systems We would be delighted to integrate these or other handling stations in your production process. A common, unified transport system is only one reason for the reliability of each station and the interaction with the upstream and downstream processes. Buffer sections and synchronisation devices are standard here, and can also be combined with our stockpiling systems.

Request for a quote

ROLEC GEHÄUSE-SYSTEME GMBH

Germany

The principle of profilPLUS allows for time-saving assembly. For this, ROLEC designers have come up with "one-screw adjustment". Suitable adapters for existing connections to panels from leading manufacturers such as Siemens, B&R, CRE Rösler and Beckhoff have also been designed. All system couplings have also been pre-fitted with a support profile as standard, saving time. The ducts in the interior of the system provide space for multiple cables such as e.g. HDMI, DVI or a network adapter. Cable protectors are integrated into all rotating system elements as standard. The integrated equipotential bonding protects humans and machinery. A set screw system in the joints serves to adjust to any pivoting range in 30° steps. For larger loads, a reducer adapter also enables connection of profiPLUS 50 to the larger profiPLUS 70 system.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

EHG electromagnetic holding rods are used in fixture construction, for gripper systems and for a wide variety of tasks in mechanical engineering. EHG holding rods consist of a screwed, two-part system, are double-coated and sealed to IP 65. Max. Operating temperature 60°C Standard voltage 24,48,110V DC Protection class IP 53 ED 100%

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Compact filters are characterised by the fact that they essentially unite fan, filter element and discharge or dust collection facility in one. The capacity range of the compact filters extends up to 20,000 m³/h. Different systems and modes of operation are available for the individual assemblies, resulting in a large number of possible variants. This allows us to offer a large range of solutions for dedusting tasks. Based on our many years of experience, we select the filter media from those available on the market that are best suited for the most diverse types of dust and tasks. Filter hoses, filter bags, filter tubes and filter cartridges are used as filter elements. Cleaning takes place using compressed air impulse, low-pressure purge-air or shaking. Fans from own development and production enable us to design a highly efficient and precise layout. Discharge usually takes place directly into collecting containers, such as dustbins with snap fasteners, or into containers, big bags, or via discharge mechanisms into automatic disposal systems. Screw conveyors, drag conveyors, rotary systems, cellular wheel sluices, double-gate sluices and slidegate valves are available as discharge mechanisms. Intelligent control systems, piping elements, silencers and pre-coating devices for auxiliary dusts are standard items in the range. Naturally we also use our know-how to create needs-based custom solutions.

Request for a quote

ABS SAFETY GMBH

Germany

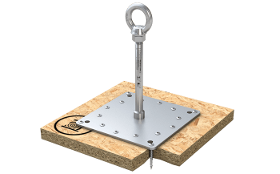

This anchorage point (Ø 16 mm) has been awarded national technical approval ("abZ"). It is equipped with a base plate (200 x 200 mm) and is screwed straight onto the wooden panelling. Our standard package includes 16 high-quality screws which - like the whole system - are manufactured from weather-resistant stainless steel material. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 National technical approval (“abZ”): OSB ≥ 22 mm, or similar, e.g. tongue and groove boards or glulam planks EN 795: Wood ≥ 24 mm, OSB ≥ 18 mm Optionally, the device can be installed using an additional 12 mm OSB board: Wood ≥ 20 mm, OSB ≥ 12 mm Incl. installation set Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Current Controlled Torque System suitable for screw fastening work Easy fastening setting by controller Lowvoltage brushless motor ESD (electrostatic discharge) protection structure For both handheld / automatic machines Nine speed settings available Automatic three step speed control function Two types of measuring methods (Time/Motor rotation signal) Seven color indication LED (At the tip of the screwdriver) Two external I/O signal connection ports (NPN PNP switchable, RS232C) Controller has built in counting function Preventing human errors Various settings can be configured via a PC (Pree setting software available on NITTO KOHKi website here) More infomation available on NITTO KOHKI website here)

Request for a quote

EISELE GMBH

Germany

- Metric thread- Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, but not designed for steady motion of the tube

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread- Chambered O-ring - Seals NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, not designed for steady motion of the tube - Not designed for steady motion of the tube

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EISELE GMBH

Germany

- Whitworth pipe thread- Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, but not designed for steady motion of the tube

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread- Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, but not designed for steady motion of the tube

Request for a quote

EISELE GMBH

Germany

— Metric thread with hexagon socket — Chambered O-ring — Sealing NBR — Material brass nickel-plated — Temperature range -4 to 176 °F (-20 to +80 °C) — Working pressure range -14 to 232 psi (-0.95 to 16 bar)

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread with hexagon socket - Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, but not designed for steady motion of the tube

Request for a quote

EISELE GMBH

Germany

— Whitworth pipe thread- Chambered O-ring — Sealing NBR — Material brass nickel-plated — Temperature range -4 to 176 °F (-20 to +80 °C) — Working pressure range -14 to 232 psi (-0.95 to 16 bar)

Request for a quote

EISELE GMBH

Germany

- with shut-off valve - M5 thread - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range 0 to 232 psi (0 to 16 bar)

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread - Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar)

Request for a quote

EISELE GMBH

Germany

- R-thread - Whitworth pipe thread conical - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar)

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

FUNCTIONAL PRINCIPLE The SOMOS® Gramix TwinDos dosing system supplies twin screw extruders in the "underfed" mode required for such extruders. Optimized hardware and control software ensure extremely short system response times, the weighing electronics operating with 24 bit signal resolution. For example, the system even responds automatically to changing regrind consistencies and optimizes itself by appropriately readjusting the metered components. No software adaptation (e.g. using appropriate material characteristic curves) is required for this purpose. The closed dosing system releases little dust and can be installed directly on the processing machine, so saving space.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

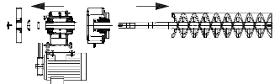

Characteristics, Function The new refiner feed screw bearing system is designed in a very maintenance-friendly wayThe bearing components, specifically the feed screw can be exchanged in no time at all and thereby increases the availability of the system.It is also possible with this design to provide the feed screw with a mechanical seal. Advantages Low downtimes Significantly increased system availability Available with mechanical seal Old feed screw can still be used

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The smartLine covers the entire spectrum of travelling table grinding machines. From simple reciprocation surface grinding through speed-stroke, slot and profile grinding all the way to creep-feed grinding. This machine concept solves every grinding task. The machine‘s versatile building block system is designed to allow almost any combination in table drive systems from belt drive to ball screw system in combination with table mounted and overhead dressing units to solve your specific grinding task. The Kombi-version of the smartLine allows individual configurations all the way up to a complex creep-feed grinding machine. Grinding width, grinding height, type of drive and spindle power as well as all variations of dressing units from simple table-mounted dressing diamond to CD-grinding with a headmounted roll dressing unit as well as an automatic tool changer for grinding wheels and dressing tools can be selected to meet specific requirements.

Request for a quoteResults for

Screw system - Import exportNumber of results

31 ProductsCountries

Company type

Category

- Hydraulic equipment (9)

- Internal transport systems (3)

- Connectors, pneumatic (2)

- Screws (1)

- Conveyor systems (1)

- Adjustment - machine tools (1)

- Concrete mixers (1)

- Electromagnets (1)

- Fastening devices (1)

- Goods handling systems, continuous (1)

- Inductive sensors (1)

- Mechanical engineering - custom work (1)

- Metal joinery, wrought-iron - machinery and equipment (1)

- Weighing and dosing equipment (1)