- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sandwiches

Results for

Sandwiches - Import export

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The special lightweight aluminium design and silicone inserts of STRATE sandwich non-return valves SB makes them ideal for: Conveying air and gases up to temperatures of 200 °C Working pressures up to 4 bar Special applications with other valve insert materials on request

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

for perforating thin aluminum sheets (eg heat protection sheets) and foils

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

SAE Blanking Flange and Counterflange BFX-CP / BAS-CP ▪ 3000 PSI Standard Pressure Series (based on ISO 6162-1:2006): 1/2" (DN13) ... 5" (DN127) ▪ 6000 PSI High Pressure Series (based on ISO 6162-2:2006): 1/2" (DN13) ... 2" (DN51) ▪ Material: S355J0 / C45 or equivalent, Stainless Steel 1.4404 on request (W5) ▪ Surface: blank, oiled SAE Sandwich Plate - Female BSP Port SPL-G1/4-L ▪ e.g. for Test Couplings ▪ 3000 PSI Standard Pressure Series (based on ISO 6162-1:2006): 1/2" (DN13) ... 2" (DN51) ▪ 6000 PSI High Pressure Series (based on ISO 6162-2:2006): 1/2" (DN13) ... 2" (DN51) ▪ Materials: S355J0 / C45 or equivalent, Stainless Steel 1.4404 on request (W5) ▪ Surfaces: blank, oiled SAE Blindplug CAG-BP SAE Blindplug (High Version) CAG-BPH ▪ 3000 PSI Standard Pressure Series (acc. to ISO 6162-1:2006): 1/2" (DN13) ... 4" (DN102) ▪ 6000 PSI High Pressure Series (acc. to ISO 6162-2:2006): 1/2" (DN19) ... 2-1/2" (DN64) ▪ Materials: S355J0 / C45 or equivalent, Stainless Steel 1.4571...

Request for a quote

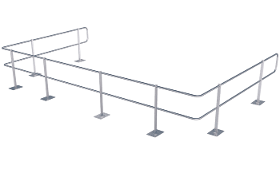

ABS SAFETY GMBH

Germany

This guard rail, which is made of aluminium and stainless steel, is simply riveted onto the profiles of a sandwich roof surface. This high-quality, collective protection system comes with a set of watertight blind rivets which have been awarded national technical approval. The handrail is 1100 mm high. EN 13374:2013, A Distance between the posts: Max. 2.50 m Specially designed for sandwich and trapezoidal sheeting (positive/negative) For steel plating ≥ 0.45 mm Distance between the holes:: 180/250 mm or 280/333 mm

Request for a quote

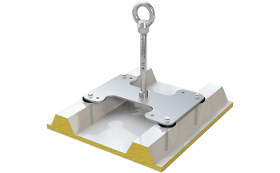

ABS SAFETY GMBH

Germany

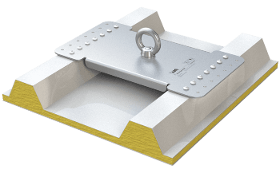

This anchorage point (Ø 16 mm) for sandwich sheeting is simply installed from above using 4 special toggle bolts. The anchorage eyelet, rod and base plate (372 x 200 mm) are all manufactured completely from stainless steel material. The special toggle bolts needed are included in the package. EN 795:2012, A + CEN/TS 16415:2013 Sandwich and trapezoidal sheeting (negative) For steel plating ≥ 0.5 mm Distance between the bores: 280 to 333 mm Installation materials included Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

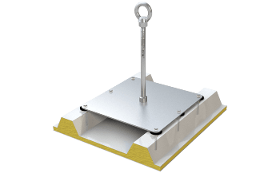

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) for aluminium sandwich sheeting is equipped with a base plate which can be supplied in custom sizes (standard: 370 x 370 mm). It is easily installed using the 6 special toggle bolts supplied. EN 795:2012, A + CEN/TS 16415:2013 Sandwich and trapezoidal sheeting (positive/negative) Aluminium ≥ 0.8 mm Distance between the rows of pre-drilled holes: 335 mm Installation materials included Upgrade with a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

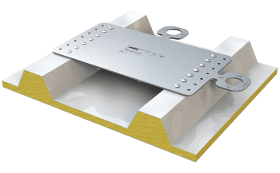

ABS SAFETY GMBH

Germany

This extremely flat stainless steel anchor does not get in the way when stacking containers. Combine 2 ABS-Lock X-Flat devices to create a temporary lifeline system. The anchor is riveted onto the subsurface from above using 14 watertight blind rivets. The integrated sealant tape prevents water from seeping in. EN 795:2012, A + CEN/TS 16415:2017 Specially designed for sandwich and trapezoidal sheeting (positive/negative) For steel plating ≥ 0.5 mm Distance between the rows of pre-drilled holes: 180-250mm / 280-333 mm Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

This stainless anchorage point can be installed on a range of different seams and is available in two models. Simply install this anchorage device from above using the stainless steel blind rivets provided. We also supply models for usage as an intermediate bracket or T-junction in a lifeline system. EN 795:2012, A + CEN/TS 16415:2017 Sandwich and trapezoidal sheeting (cold roofs) For steel plating ≥ 0.45 mm; Aluminium ≥ 0.8 mm Distance between the holes: 180-250 mm / 280-333 mm Installation materials included

Request for a quote

PANEL SELL GMBH

Germany

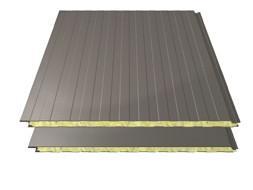

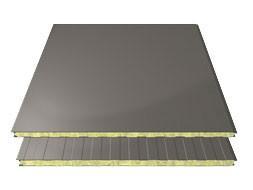

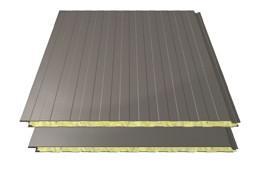

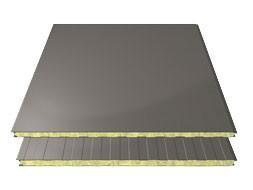

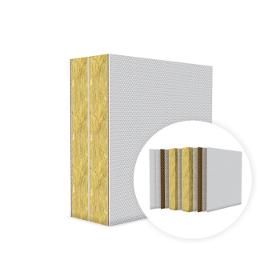

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

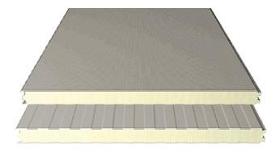

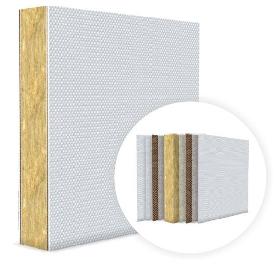

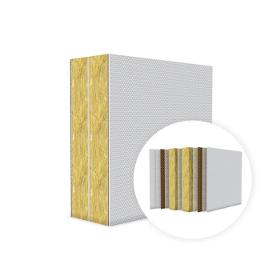

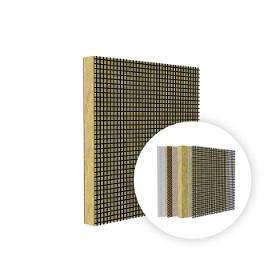

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

CBG COMPOSITES GMBH

Germany

Composite sandwich panel on basalt and ceramic basis for the production of fire-resistant building constructions. CBG-SeaPan-OEM-50/60 offers completely new solutions for heat, sound and fire protection application. The use of lightweight composite materials makes it possible to reduce the total weight of a construction considerably. - 100% of natural origin, chemically neutral — corrosion resistant — non-flammable — non-combustible — resistant to humidity — antibacterial — recyclable — no smouldering — dimensionally stable

Request for a quote

CBG COMPOSITES GMBH

Germany

Fire-resistant composite sandwich core panel on basalt and ceramic basis for the production of fire-resistant constructions and refractory building structures in the field of building construction and container construction, as well as comparable applications ✓ 100% natural and chemical neutral ✓ antibacterial ✓ corrosion-resistant ✓ thermoresistant ✓ pressure-resistant ✓ water-repellent ✓ reducevibration ✓ fire-resistant ✓ nonflammable ✓ recyclable

Request for a quote

CBG COMPOSITES GMBH

Germany

Fire-resistant composite sandwich panel based on basalt and ceramic. CBG SeaPan WP 25/15 offers completely new solutions to the manufacture of cabin walls and bulkheads in shipbuilding, residential and office containers in construction sphere. The use of lightweight composite materials (e.g. with only approx. 7.99 kg/m2 for a wall panel of fire class A-30) makes it possible to significantly reduce the total weight of a construction. ✓ 100% natural and chemically neutral ✓ antibacterial ✓ corrosion-resistant ✓ thermoresistant ✓ pressure-resistant ✓ water-repellent ✓ reduce vibration ✓ fire-resistant ✓ nonflammable ✓ recyclable

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CBG COMPOSITES GMBH

Germany

Industrial insulation panel as composite double core panel on basalt and ceramic basis. CBG-SeaPan-OEM-57/150 offers completely new solutions for heat, sound and fire protection application. The use of lightweight composite materials makes it possible to reduce the total weight of a construction considerably. — 100% of natural origin, chemically neutral — corrosion resistant — non-flammable — non-combustible — resistant to humidity — antibacterial — recyclable — no smouldering

Request for a quote

CBG COMPOSITES GMBH

Germany

Industrial insulation panel as composite double core panel on basalt and ceramic basis. CBG-SeaPan-OEM-54/120 offers completely new solutions for heat, sound and fire protection application. The use of lightweight composite materials makes it possible to reduce the total weight of a construction considerably. — 100% of natural origin, chemically neutral — corrosion resistant — non-flammable — non-combustible — resistant to humidity — antibacterial — recyclable — no smouldering

Request for a quote

CBG COMPOSITES GMBH

Germany

Industrial insulation panel as composite double core panel on basalt and ceramic basis. CBG-SeaPan-OEM-51/100 offers completely new solutions for heat, sound and fire protection application. The use of lightweight composite materials makes it possible to reduce the total weight of a construction considerably. — 100% of natural origin, chemically neutral — corrosion resistant — non-flammable — non-combustible — resistant to humidity — antibacterial — recyclable — no smouldering

Request for a quote

CBG COMPOSITES GMBH

Germany

CBG SeaPan WP 25/G offers completely new solutions to the manufacture of cabin walls in shipbuilding. The use of lightweight composite materials makes it possible to significantly reduce the total weight of a construction with e.g. only approx. 7.8 kg/m2 for a wall panel of fire class B-15. A special feature of this panel is its excellent sound insulation. — 100% natural origin, chemically neutral — non-combustible — no smouldering — no smoke emission in case of fire — antibacterial — corrosion-resistant — pressure-resistant — vibration damping — recyclable — water repellent — good air permeability — thermoresistant

Request for a quote

CBG COMPOSITES GMBH

Germany

CBG SeaPan WP 15/G offers completely new solutions to the manufacture of cabin walls in shipbuilding. The use of lightweight composite materials makes it possible to significantly reduce the total weight of a construction with e.g. only approx. 5,25 kg/m2 for a wall panel of fire class B-15. A special feature of this panel is its excellent sound insulation. — 100% natural origin, chemically neutral — non-combustible — no smouldering — no smoke emission in case of fire — antibacterial — corrosion-resistant — pressure-resistant — vibration damping — recyclable — water repellent — good air permeability — thermoresistant

Request for a quote

DSMART GMBH

Germany

Production Process of food storage jar shaped bags A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of food storage jar shaped bags A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Professional flexible packaging bag manufacturer Good quality and competitive price Welcome to visit our factory

Request for a quoteResults for

Sandwiches - Import exportNumber of results

24 ProductsCountries

Company type